High-precision multi-shaft automatic turning process of wood

A high-precision, automatic car technology, applied in wood processing equipment, woodworking lathes, manufacturing tools, etc., can solve problems affecting the processing accuracy of wood workpieces, and achieve the effect of ingenious structure and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

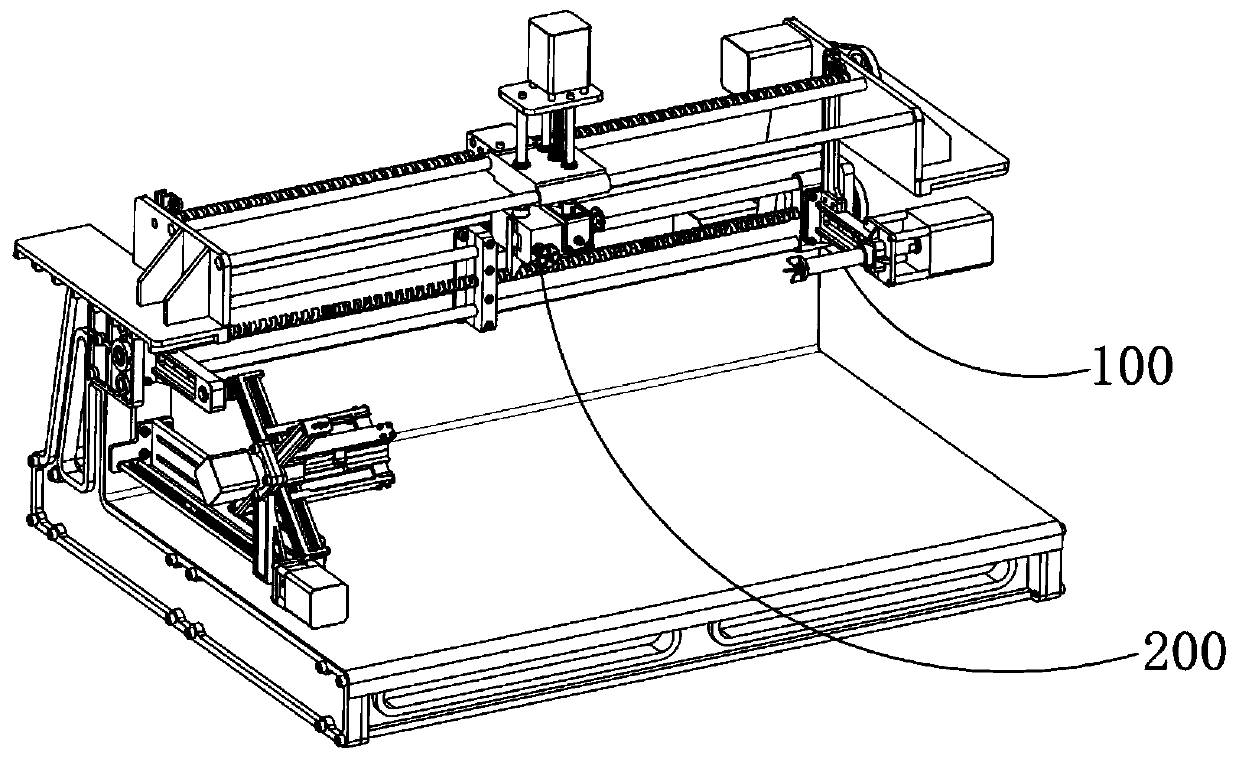

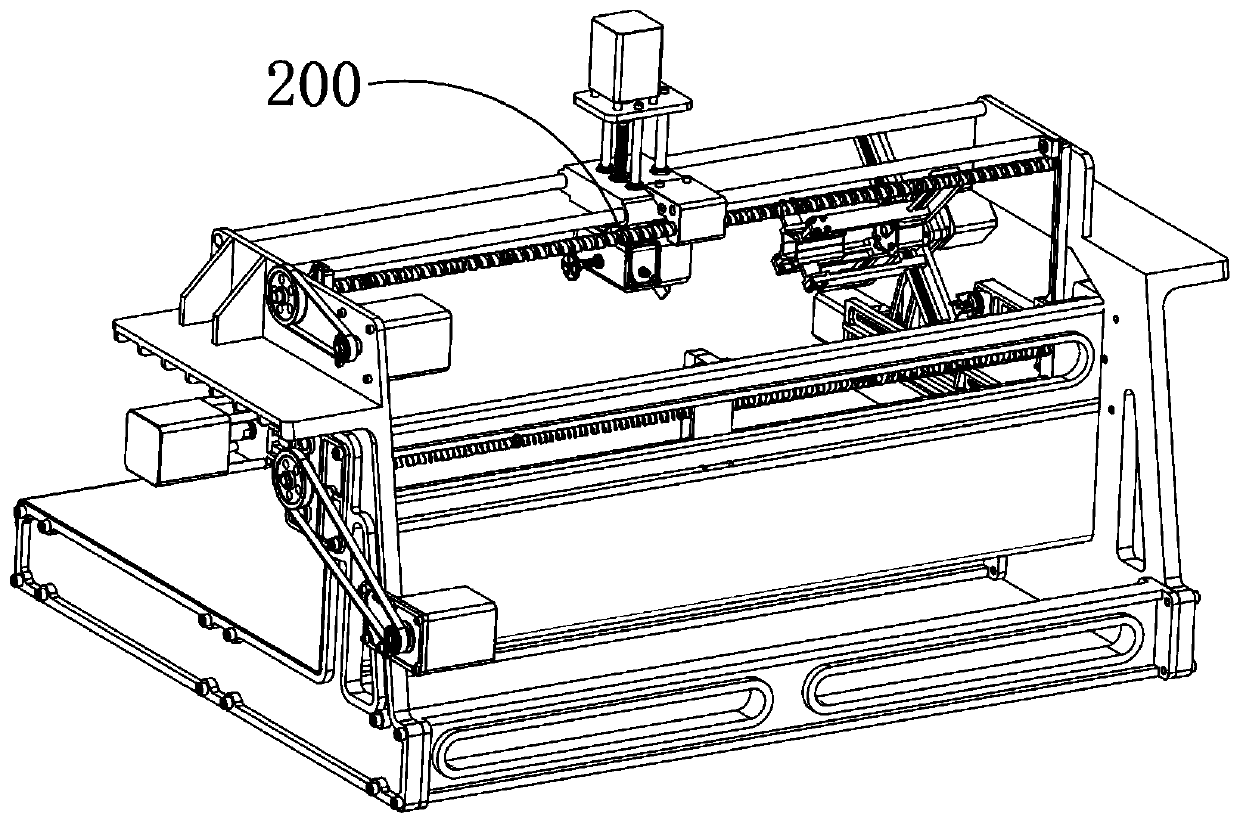

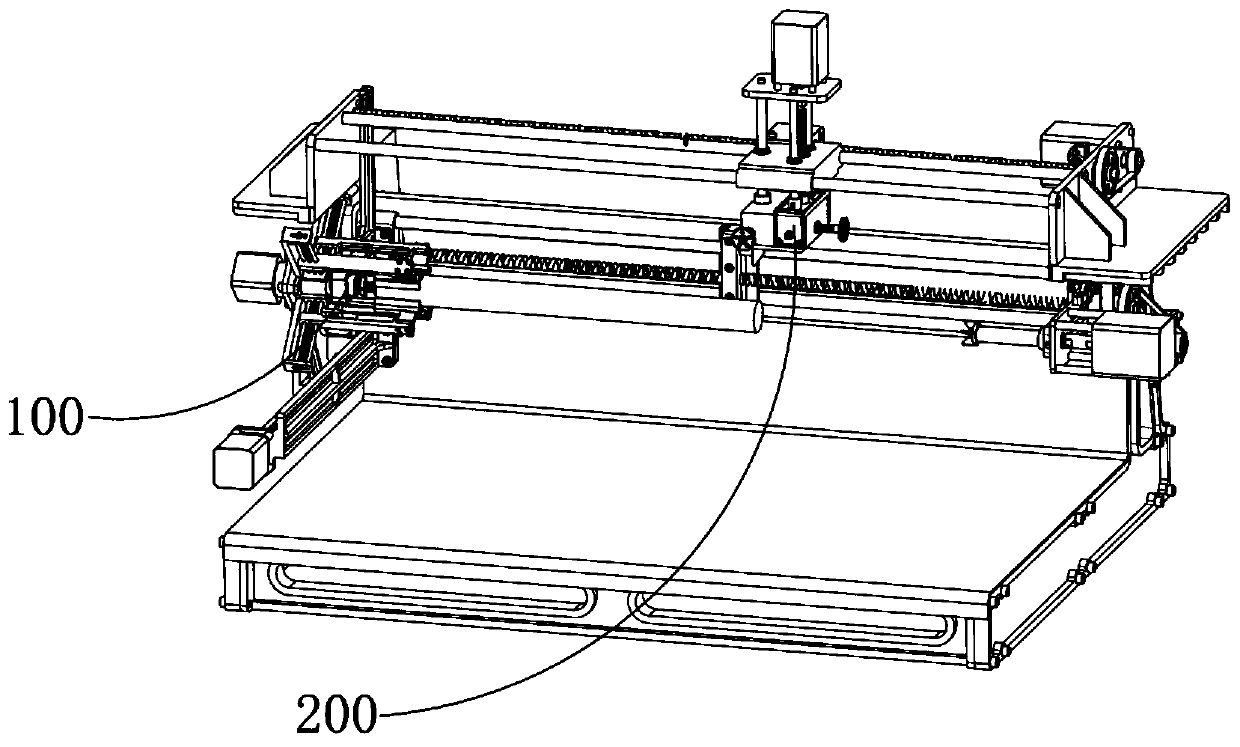

Image

Examples

Embodiment Construction

[0054] The high-precision multi-axis automatic turning process of wood, its steps are:

[0055] (1) Clamping self-centering stage;

[0056] S1: Insert one end of the rod-shaped wood workpiece between the clamping corner blocks 126d of the self-centering feeding mechanism 120, and the clamping corner blocks 126d move close to each other synchronously and perform self-centering clamping on the rod-shaped wood workpiece;

[0057] The self-centering feeding mechanism 120 includes a second mounting frame 121 fixedly installed on the lower end of the first slide block 115a and the second mounting frame 121 is arranged along the width direction of the bed 111. There are two feeding guide rods 122 in the width direction, and there are two feeding guide rods 122 arranged symmetrically along the width direction parallel to the bed 111. The feeding guide rod 122 is covered with a vertically upwardly arranged support frame 123 , the support frame one 123 is matched with the feeding guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com