Roller self-positioning device for bearing press-in machines

A self-positioning, press-in machine technology, used in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of cumbersome operation, time-consuming and laborious, etc., to reduce rigid damage, eliminate inconsistency, and pick and place rollers. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

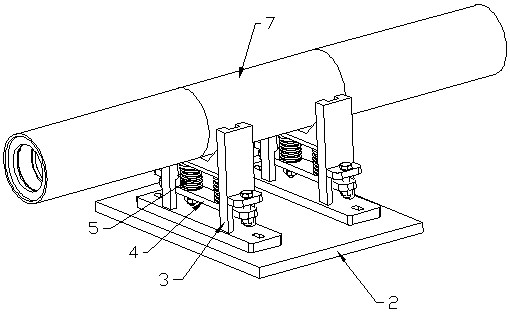

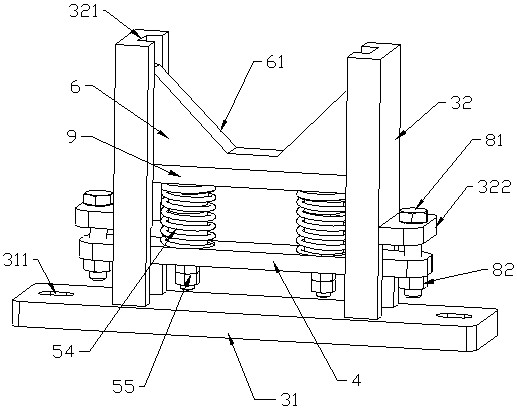

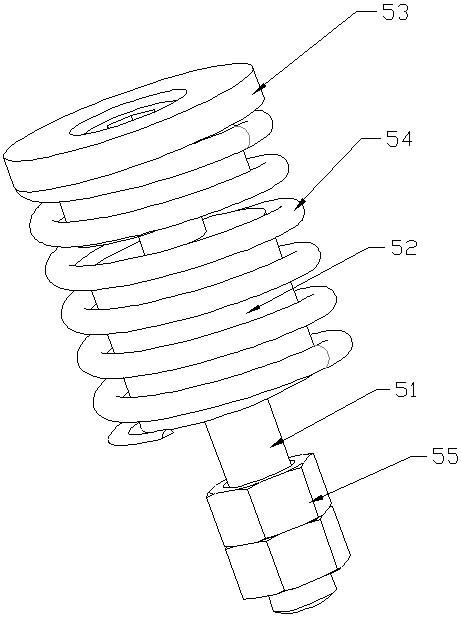

[0025] See attached Figure 1-5 As shown, a roller self-positioning device for a bearing press-in machine of the present invention is located between two bearing press-in mechanisms, and includes a base 2 fixed on the machine table, and the base 2 is provided with There is a frame 3 that can move laterally driven by the horizontal fine-tuning mechanism, and a clamping assembly that can move vertically driven by the vertical fine-tuning mechanism is arranged on the frame 3 . The clamping assembly includes a support plate 4 connected to the vertical fine-tuning mechanism, and an elastic buffer portion 5 for supporting the clamping portion is provided on the support plate 4 . The clamping part includes a V-shaped iron 6 slidably arranged on the frame 3 , and a V-shaped groove 61 for clamping the roller 7 is provided on the upper end of the V-shaped iron 6 .

[0026] It should be noted that the bearing press-in mechanism in this embodiment is a supporting mechanism of the roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com