Vehicle lamp driving method and device, and vehicle

A driving device and lamp technology, applied in the field of automobiles, can solve the problems of increasing the difficulty of designing LED modules, slowing the movement speed of mechanical structures, and increasing the cost of LED modules, so as to simplify the design difficulty, reduce the cost of the whole lamp, and improve Toggle the effect of responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0053] The present invention will be described in detail below with reference to the accompanying drawings and examples.

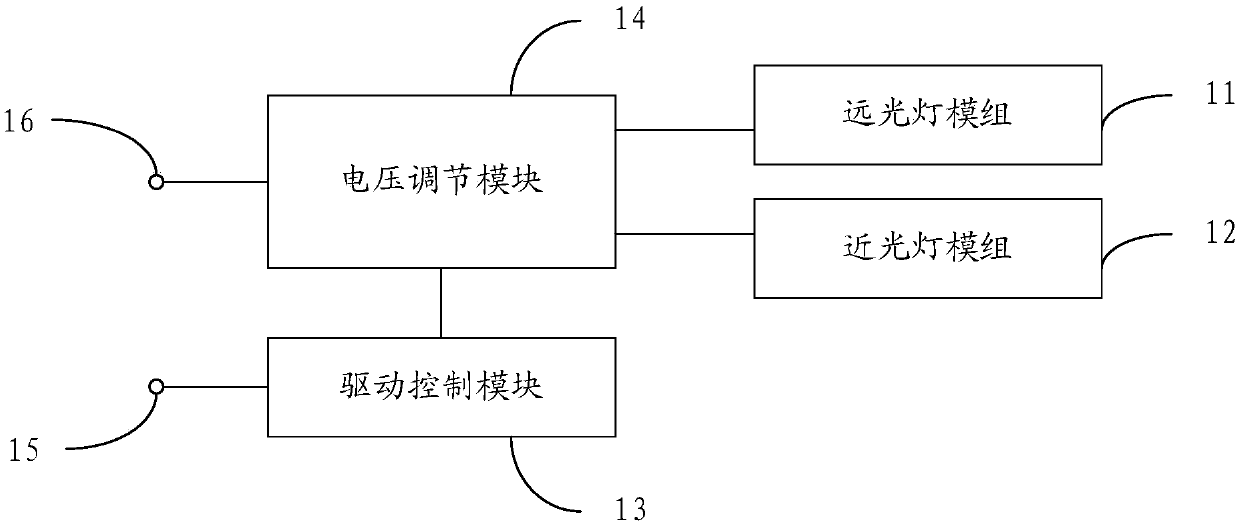

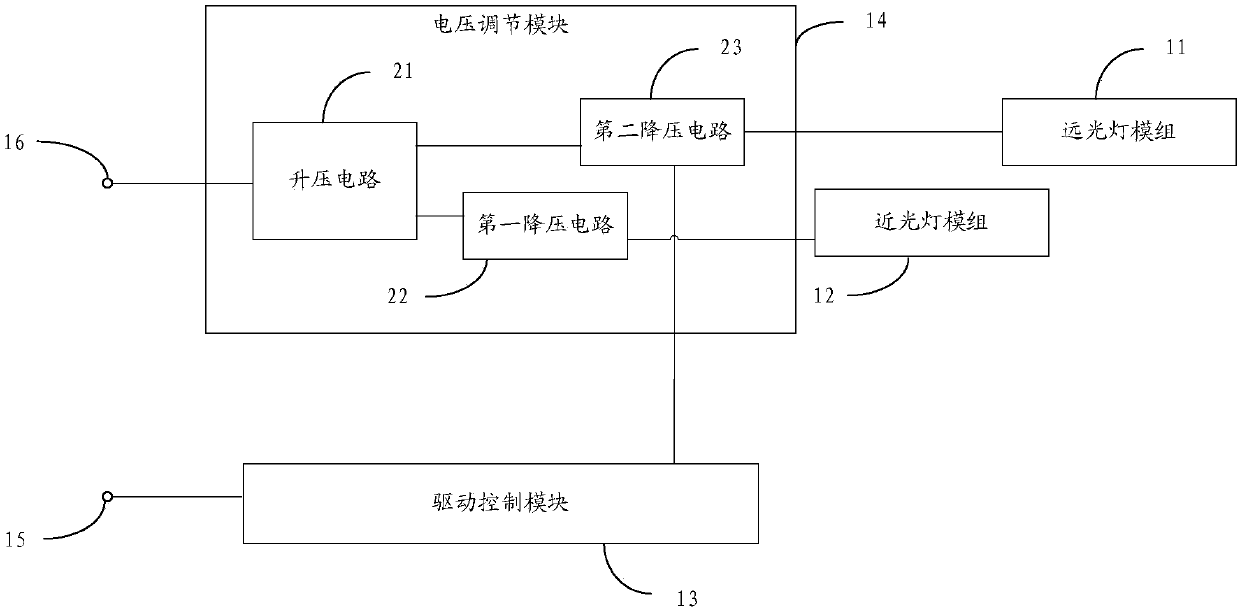

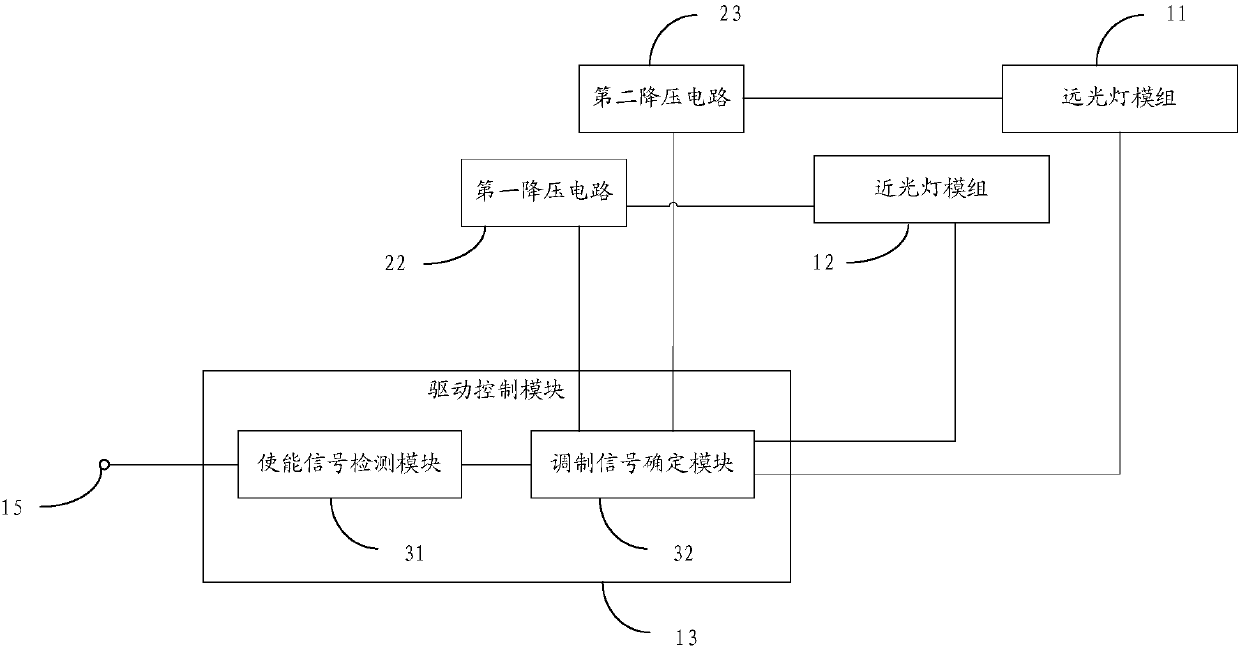

[0054] In an embodiment provided by this application, refer to figure 1 , shows a structural block diagram of a car light driving device, the car light driving device is used in a vehicle, the vehicle includes a high beam light module 11 and a low beam light module 12, and the car light driving device may include: a driving control module 13 and a voltage regulation module 14 . The drive control module 13 is connected to the enable signal input terminal 15 and the voltage regulation module 14 respectively; it is used for outputting a control signal to the voltage regulation module 14 when the high beam enable signal is detected. The voltage regulation module 14 is also connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com