Replacement method of inter-electrode insulating sleeve of generator collector ring

An insulating sleeve and inter-electrode insulation technology, applied in the direction of collector maintenance, etc., can solve the problems of inability to replace insulation in time, unqualified collector rings, and low frequency of replacement, so as to reduce construction difficulty, shorten the replacement period, The effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

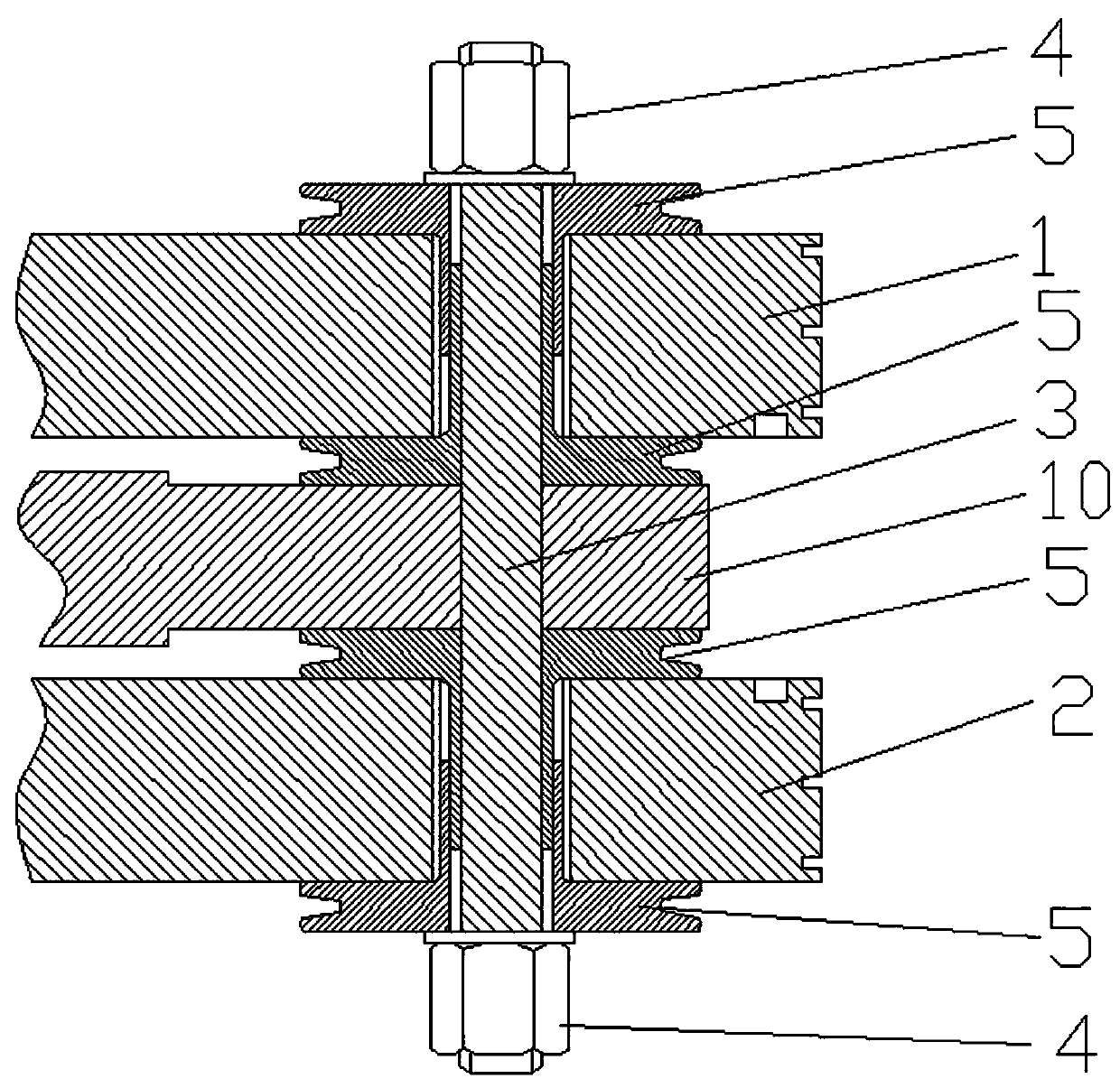

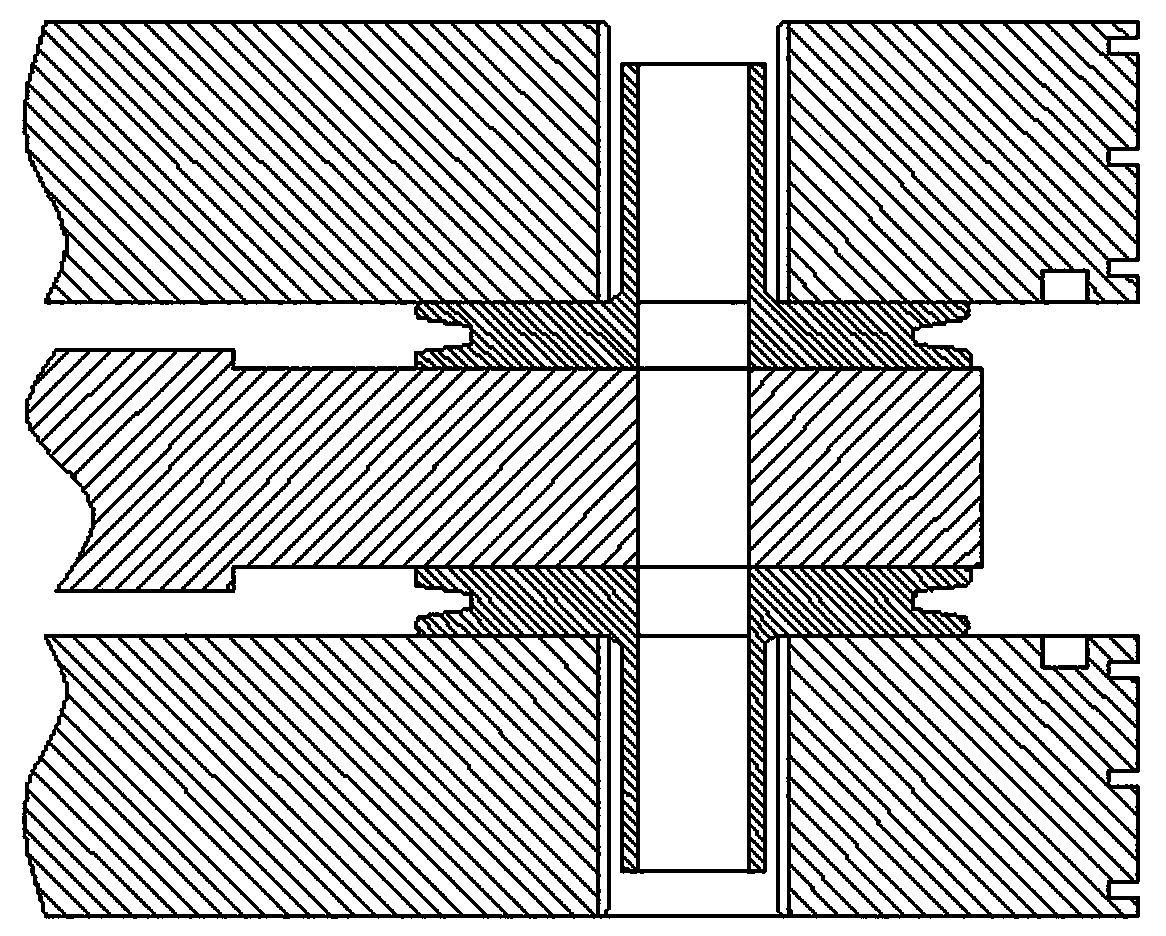

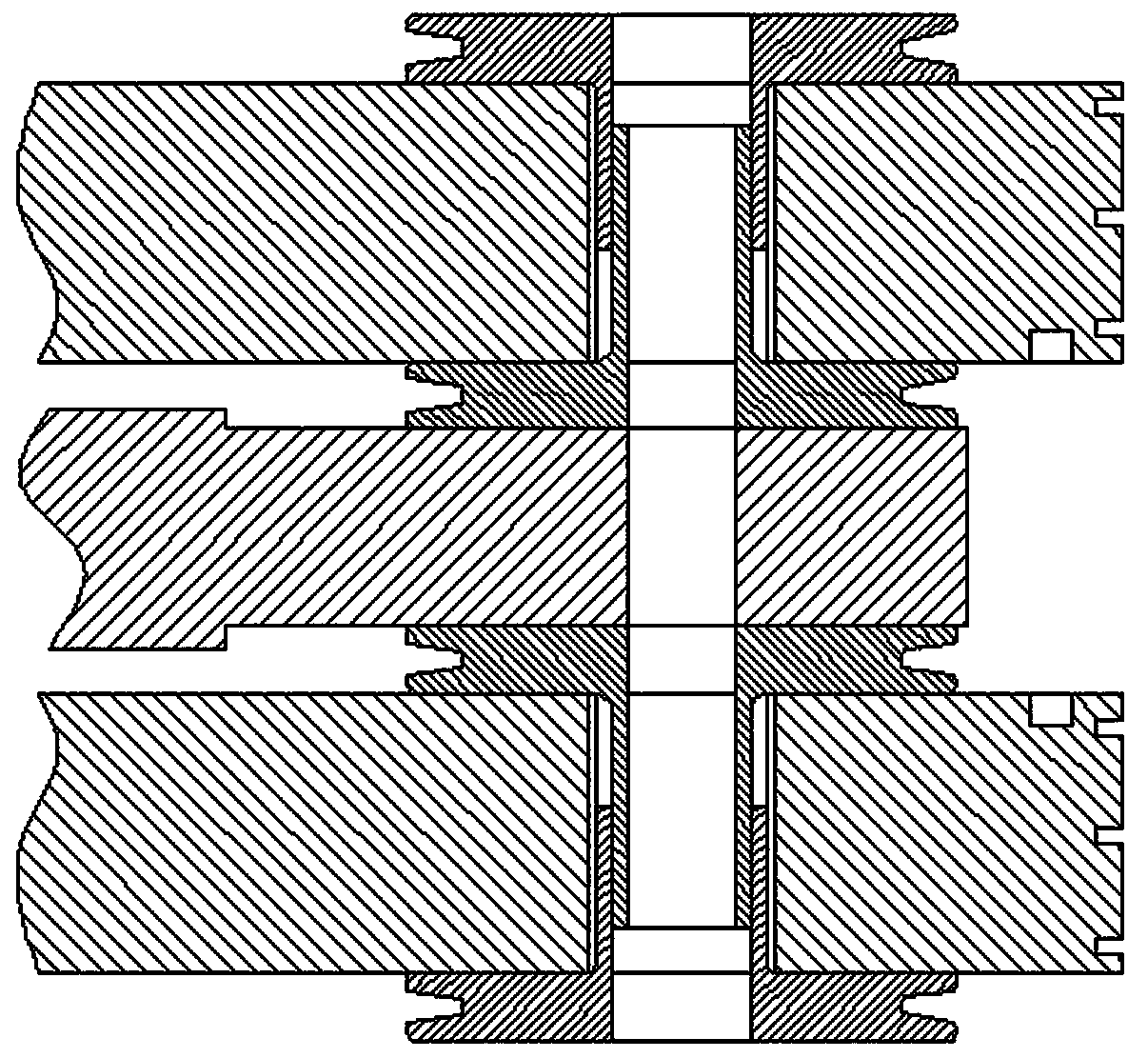

[0042] Such as Figures 1 to 14 As shown, a method for replacing the insulating bushing between poles of the collector ring of a generator, it includes the following steps:

[0043] Step 1): Remove part of the tension bolt 3 and the corresponding tension nut 4 between the upper collector ring 1 and the lower collector ring 2, and then place the upper surface of the upper collector ring 1 and the lower collector ring 2 One part of the insulating sleeve 5 on the surface is replaced;

[0044] Step 2): Install the operating screw 6 and the operating nut 7 on the upper collector ring 1 and the lower collector ring 2, and then remove the tension bolt 3 and the remaining part between the upper collector ring 1 and the lower collector ring 2 Tighten the nut 4, and replace the insulating sleeve 5 located on the upper surface of the upper col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com