Flexible conductive composite film for sensor and preparation method thereof, and flexible sensor

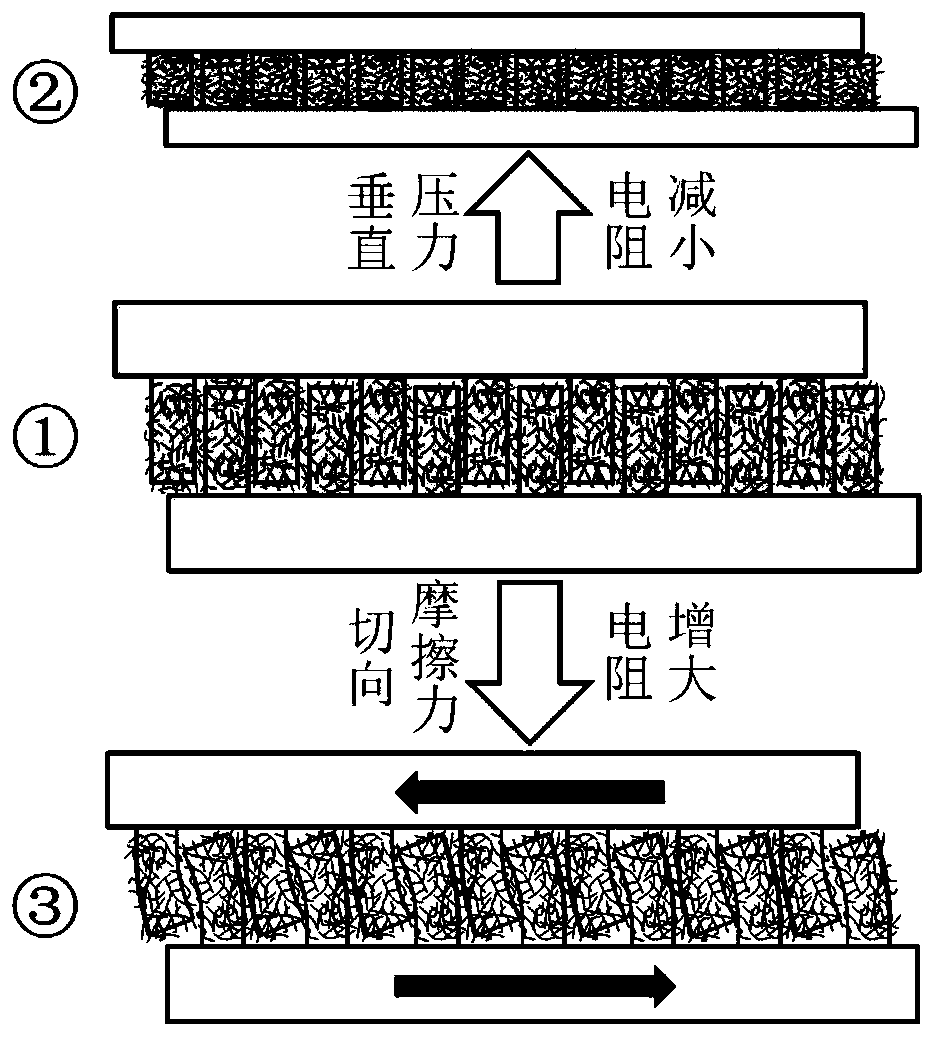

A flexible conductive and composite film technology, which is applied in the field of conductive composite films and flexible sensors, can solve the problems of flexible sensor sensitivity, poor mechanical tolerance and environmental tolerance, and achieve the effect of improving sensitivity and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

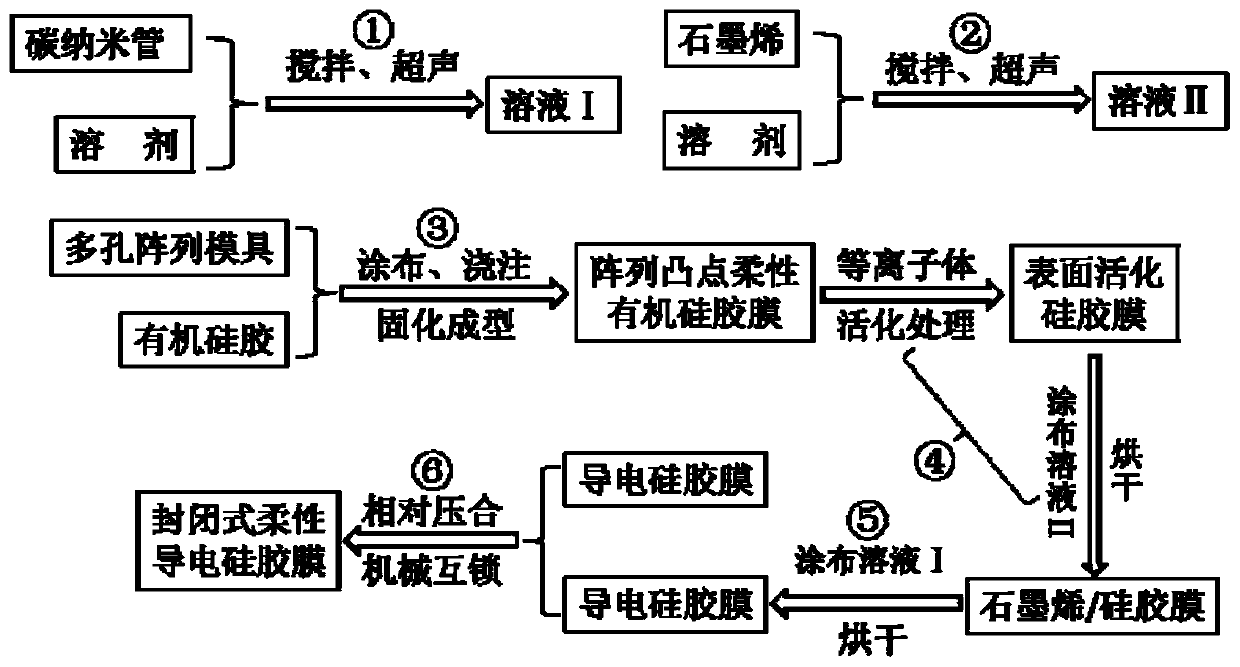

[0040] The preparation method of the flexible conductive composite film for the sensor of the present embodiment comprises the following steps:

[0041](1) Take 0.2 g of multi-walled carbon nanotubes; place them in 40 ml of N,N-dimethylformamide (abbreviated as DMF) solvent, and then undergo shearing and stirring for 30 min and ultrasonic dispersion for 1 h to obtain uniformly dispersed carbon nanotubes. nanotube dispersion. Take 0.2g of graphene and place it in 40ml of DMF solvent, then shear and stir for 30min, and ultrasonically disperse for 1h to obtain a uniformly dispersed graphene dispersion.

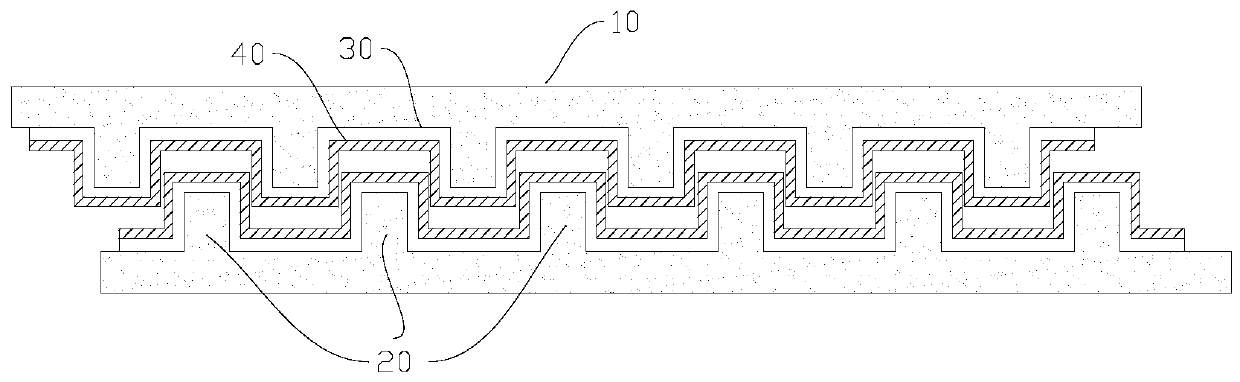

[0042] (2) Preparation of flexible bump array silicone membrane: the template cylinder used has a pore diameter of 100 microns, a depth of 100 microns, and a hole spacing of 125 microns. The silicone precursor solution was uniformly coated on the template, and then cured and stripped at 120° C. for 2 hours to obtain a silicone film with a bump array.

[0043] (3) After the orga...

Embodiment 2

[0047] The preparation method of the flexible conductive composite film for the sensor of the present embodiment comprises the following steps:

[0048] (1) Take 0.6 g of multi-walled carbon nanotubes; place them in 40 ml of DMF solvent, and then undergo shearing and stirring for 30 min and ultrasonic dispersion for 1 h to obtain a uniformly dispersed carbon nanotube dispersion. Take 0.6g of graphene and place it in 40ml of DMF solvent, shear and stir for 30min, and ultrasonically disperse for 1h in turn to obtain a uniformly dispersed graphene dispersion.

[0049] (2) Preparation of flexible bump array organic silica gel membrane: the template cylinder used has a pore diameter of 100 microns, a depth of 100 microns, and a hole spacing of 125 microns. The silicone precursor solution was uniformly coated on the template, and then cured and stripped at 120° C. for 2 hours to obtain a silicone film with a bump array.

[0050] (3) After the organic silica gel membrane is treated ...

Embodiment 3

[0054] The preparation method of the flexible conductive composite film for the sensor of the present embodiment comprises the following steps:

[0055] (1) Take 1 g of multi-walled carbon nanotubes; place them in 40 ml of DMF solvent, and then undergo shearing and stirring for 30 min, and ultrasonic dispersion for 1 h to obtain a uniformly dispersed carbon nanotube dispersion. Take 1 g of graphene and place it in 40 ml of DMF solvent, and then undergo shear stirring for 30 min and ultrasonic dispersion for 1 h to obtain a uniformly dispersed graphene dispersion.

[0056] (2) Preparation of flexible bump array organic silica gel membrane: the template cylinder used has a pore diameter of 100 microns, a depth of 100 microns, and a hole spacing of 125 microns. The silicone precursor solution was uniformly coated on the template, and then cured and stripped at 120° C. for 2 hours to obtain a silicone film with a bump array.

[0057] (3) After the organic silica gel film is treat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com