Ventilation equipment for preparing chlorine gas in chemical laboratory

A technology for chemical laboratory and ventilation equipment, which is applied in the field of ventilation equipment for chlorine gas preparation in chemical laboratory, can solve the problems of casualties, no strong absorption and absorption effect of toxic gas, leakage of toxic gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0023] In order to make the technical solution of this application more complete and detailed, some supplements and explanations are made on the basis of the above-mentioned embodiment 1, so that the technical means adopted in this application are disclosed more fully. Specifically, the technical characteristics of the added part are as follows: , the two sides of the lower part of the equipment frame 1 are provided with leaf springs, the central upper end of the leaf spring is fixedly connected to the bottom of the equipment outer frame, and the two sides of the lower end of the leaf spring are respectively connected with rollers, and the shock absorption of the equipment is carried out through the leaf springs to prevent the blower from blowing when the fan is working. The resulting vibrations affect the experimental performance.

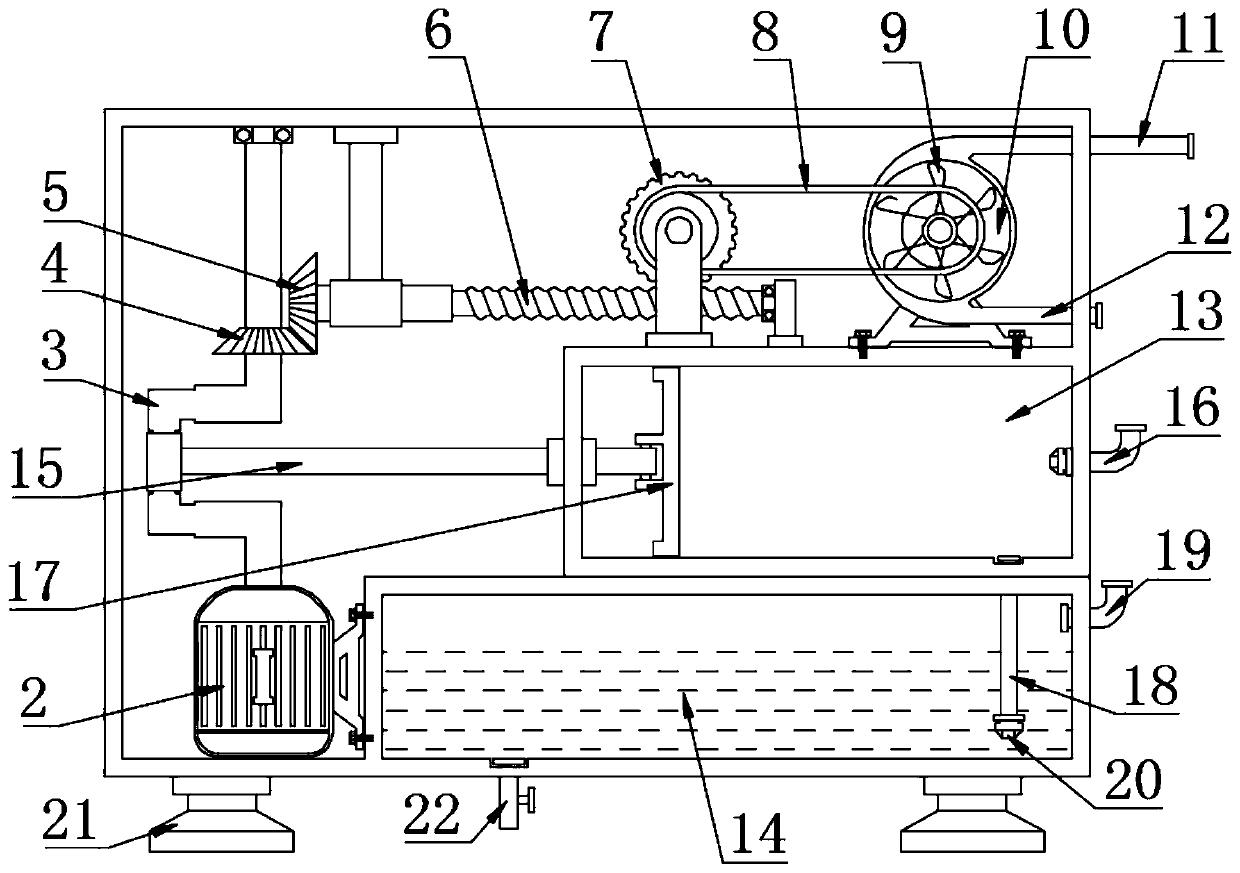

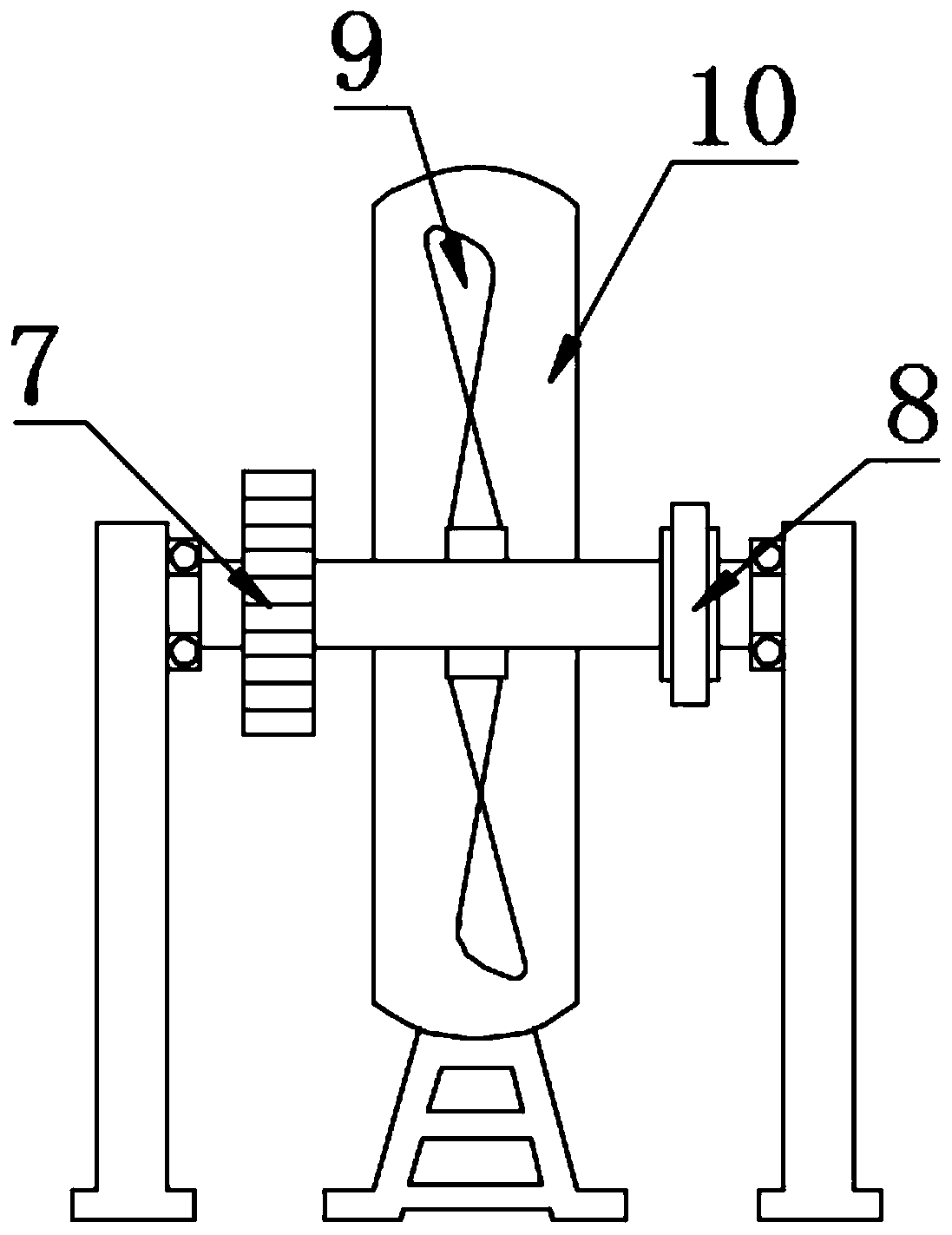

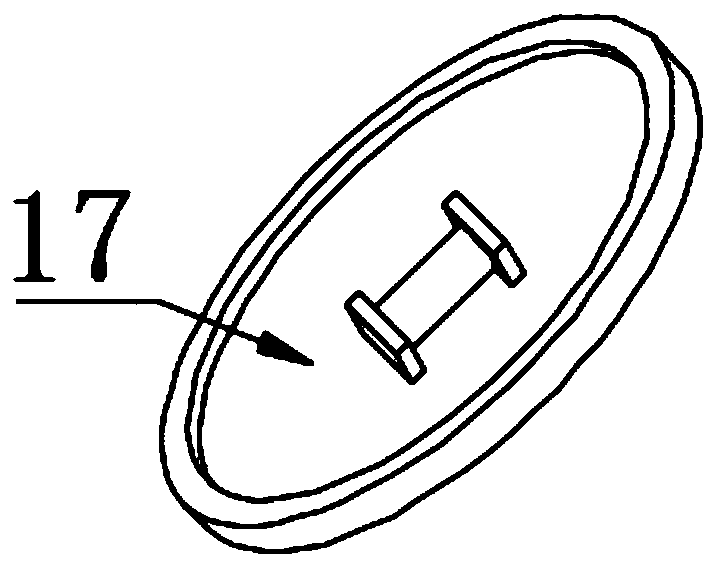

[0024] The working principle of the present invention is: press the switch so that the drive motor 2 is energized to drive the crankshaft 3 to rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com