Automatic cutting machine for non-woven fabric

A non-woven and cutting machine technology, which is applied in the cutting of textile materials, textile and paper making, metal processing, etc. Complete cutting and other problems to achieve the effect of improving cutting accuracy, good cutting effect and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

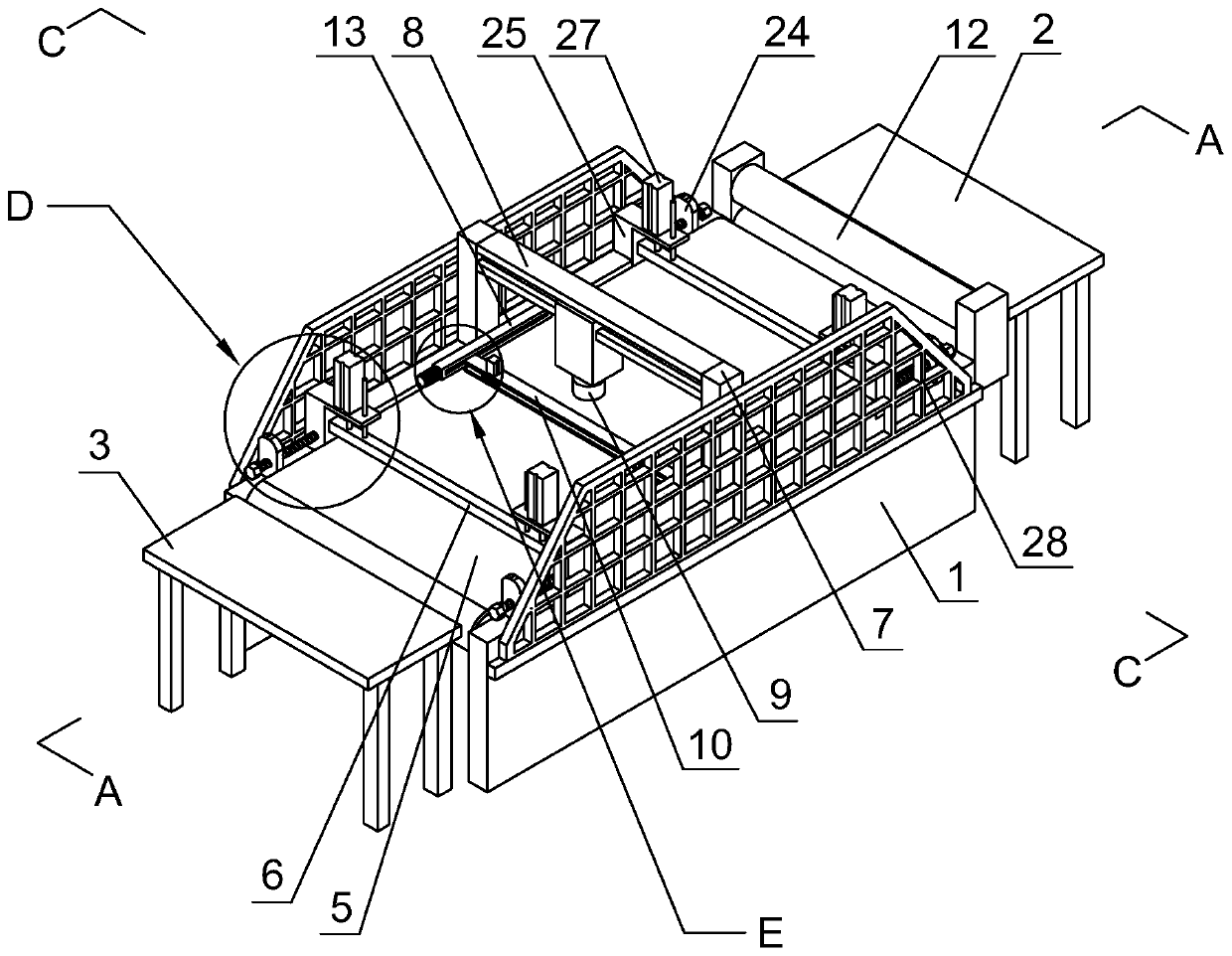

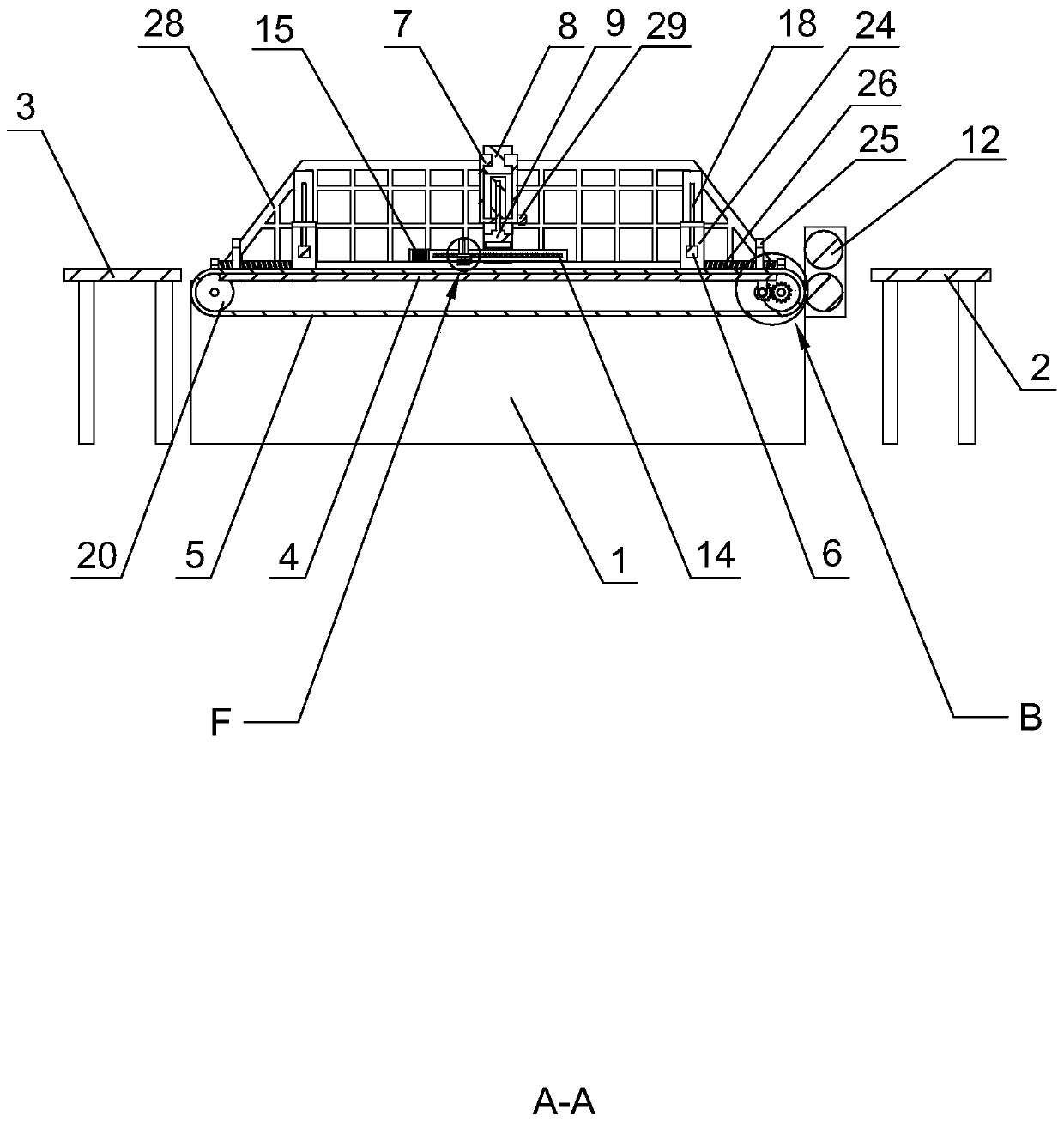

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0042] refer to figure 1 , is the automatic cutting machine of a kind of non-woven fabric disclosed by the present invention, comprises body 1, loading table 2, unloading table 3, refer to figure 2 , a workbench 4 is fixed inside the body 1, and the workbench 4 is in the shape of a cuboid.

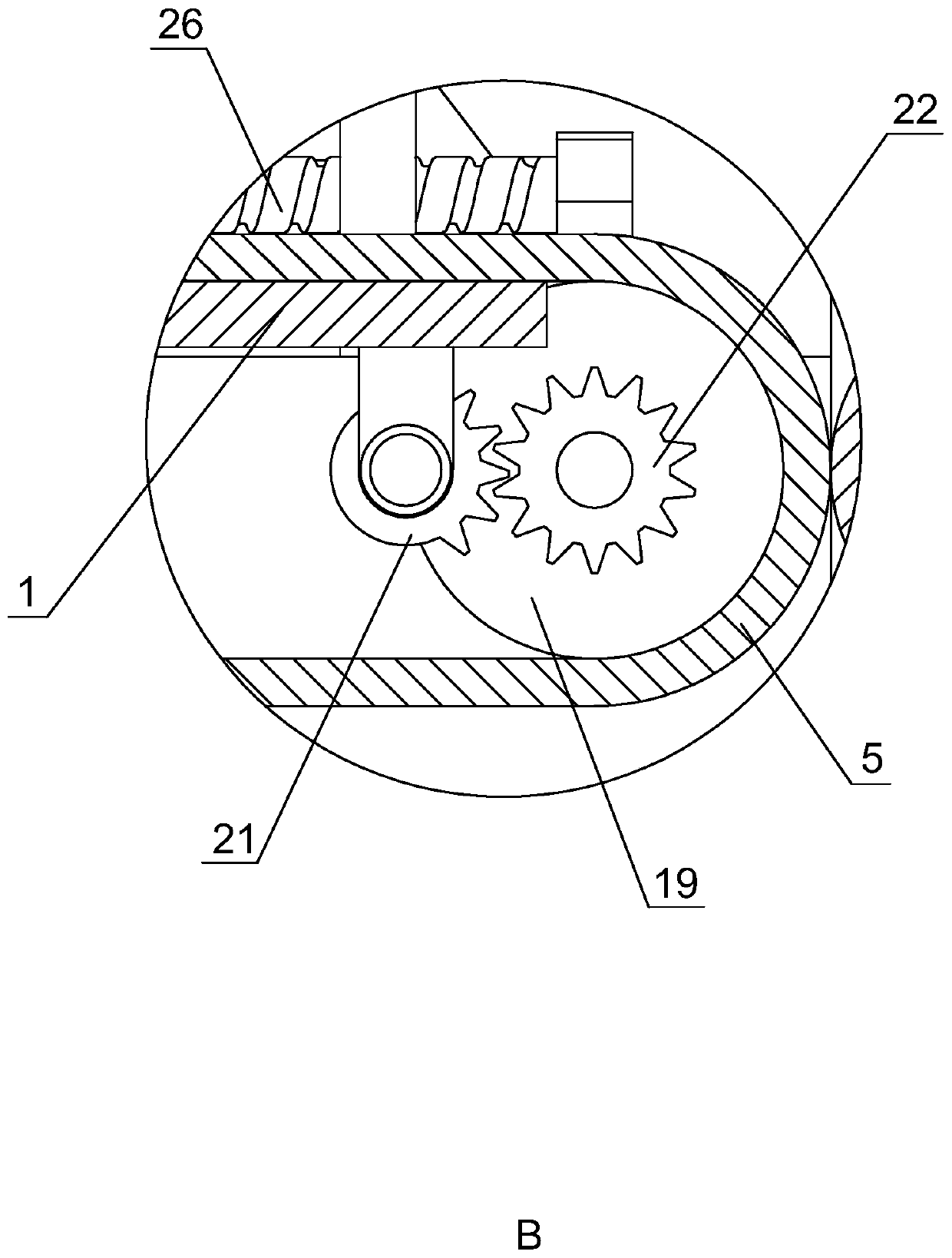

[0043] refer to figure 1 and figure 2 The side of the machine body 1 close to the feeding table 2 is rotated sequentially along the height direction of the machine body 1, and two flattening rollers 12 are arranged. The axis of the flattening rollers 12 extends along the width direction of the workbench 4. Arranged parallel to each other, the same ends of the two flattening rollers 12 are coaxially fixed with intermeshing power gears, and the body 1 is fixed with a servo motor driving the rotation of the flattening rollers 12 at the end of one of the flattening rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com