A 3D printed protective material with high negative Poisson's ratio interwoven structure

A technology of protective material and negative Poisson's ratio, which is applied in the field of new 3D printing protective materials of interwoven structures with high negative Poisson's ratio, to achieve good buckling strength, good attenuation characteristics, and good vibration isolation and sound insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

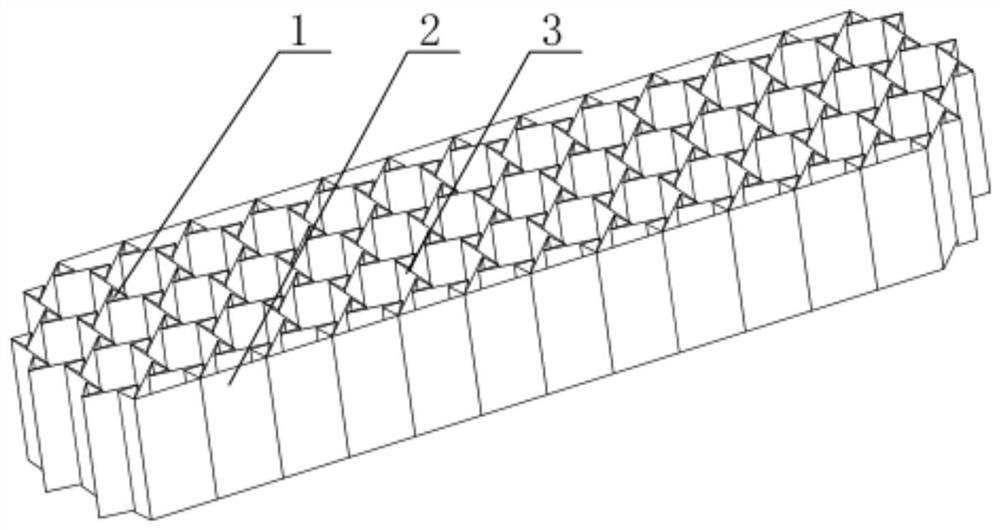

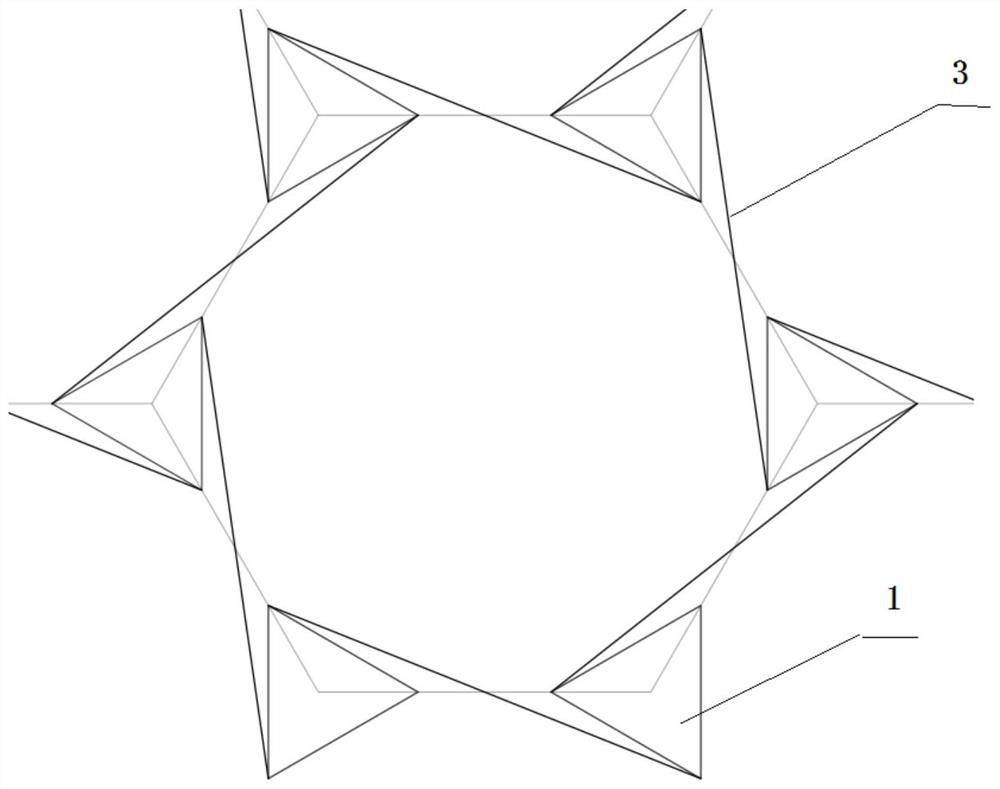

[0024] refer to figure 1 , use 3D-printable common material (silica gel) with good tensile properties on the straight line, use bisphenol F epoxy acrylate resin (containing thinner TPGDA, photoinitiator BDK) for triangular nodes, and use CAD to precisely design Produce the structure (the design parameter is that the center distance of the circumscribed circle of the triangle is 10mm, and the side lengths of the triangle are respectively 1mm, 2.5mm, and 4mm), and use 3D printing technology to form a complete composite structure with a high negative Poisson's ratio structure; finally By using ABAQUS software to test its mechanical properties, it is concluded that the Poisson's ratio of the high negative Poisson's ratio structure combined with shape memory materials can reach -0.6, and it has high specific strength, large specific modulus, and good fatigue resistance. The tensile strength is high, but at the same time the elongation at break has a certain decrease. At the same ti...

Embodiment 2

[0027] refer to figure 1 , use 3D-printable ordinary materials (rubber) with good tensile properties in the straight line, pentaerythritol triacrylate resin is used in the triangle nodes, and the structure is precisely designed by using CAD (the diameter of the inscribed circle of the triangle is 10mm, 15mm, 20mm ,), use 3D printing technology (object's connex series) to form a complete composite structure with a high negative Poisson's ratio structure at the same time; finally, by using ABAQUS software to test its mechanical properties, it is concluded that the shape memory The Poisson's ratio of the high negative Poisson's ratio structure combined with materials can reach -0.6.

[0028] The pentaerythritol triacrylate resin uses toluenesulfonic acid as a catalyst, adopts a polymerization inhibitor PMT, a decolorizing agent TSJ-1, and the amount of the catalyst is 4% of the quality of pentaerythritol, and the addition of the polymerization inhibitor is 4% of the quality of ac...

Embodiment 3

[0031] In the same way as in Example 2, the present embodiment adopts the modified octadecyl acrylate at the triangular node, which is the monomer octadecyl acrylate, crosslinking agent propoxylated neopentyl glycol diacrylate and diluted The photoinitiator is prepared by reacting under the action of a photoinitiator; the photoinitiator is a benzoin ether-sulfur salt initiator (6wt%); the mass ratio of the monomer to the crosslinking agent is 1:0.18.

[0032] By using ABAQUS software to test its mechanical properties, it is concluded that the Poisson's ratio of the high negative Poisson's ratio structure combined with the shape memory material can reach -0.53.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com