Cross sliding roof type liner device for pipe welding

A padding and cross technology, applied in the field of padding devices, can solve problems such as narrow radial space, and achieve the effects of convenient operation, improved work efficiency and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

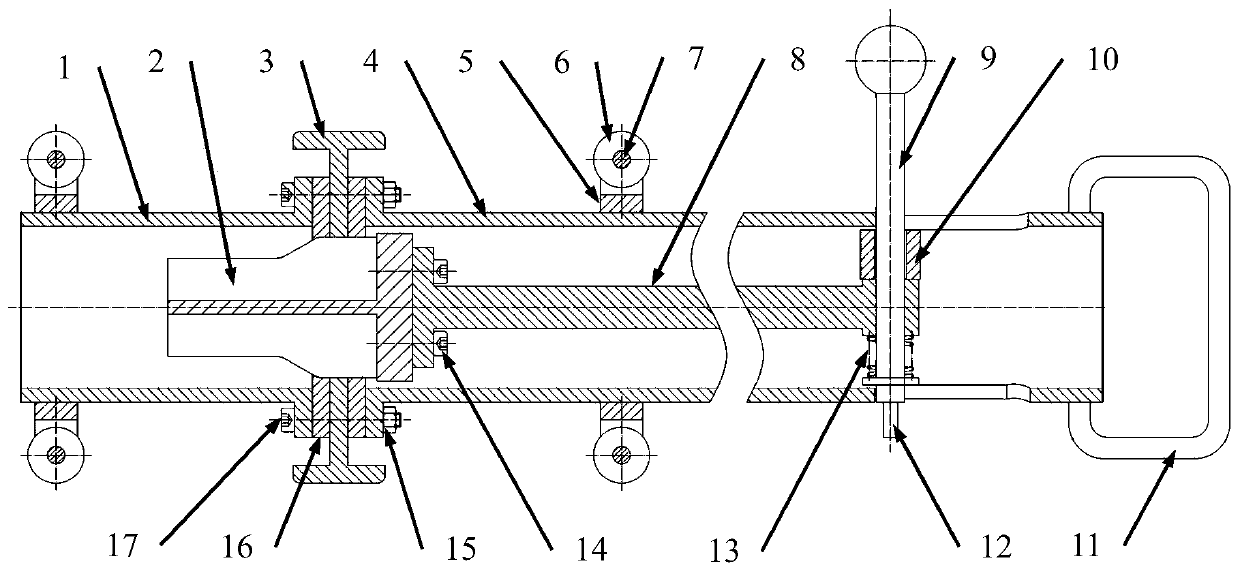

[0039] The present invention will be further described below in conjunction with accompanying drawing:

[0040] Depend on Figure 1 to Figure 21 As shown, the device consists of: front support cylinder, cross carriage, small arc liner, large arc liner, split slideway, slideway blocking plate, positioning pin, slideway screw, nut, slideway spring, guide Wheel seat, small guide wheel, small pin shaft, long connecting cylinder, push-pull rod, carriage screw, push-pull handle, wear-reducing ring, lock head, lock spring, fixed handle.

[0041] The front support cylinder is a short cylinder for supporting the front of the device; the rear end surface of the front support cylinder is flange-shaped, and is connected with the front flange of the long connecting cylinder through slideway screws.

[0042] The cross carriage is a cross-shaped sliding body, and the four cross-shaped ribs are divided into two groups, the upper and lower ribs form a group, and the left and right ribs form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com