Concrete placing boom

A concrete and placing machine technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of inconvenient work environment for workers to enter, high quality requirements for concrete pouring, etc., and achieve light weight, beautiful structure, and high control precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

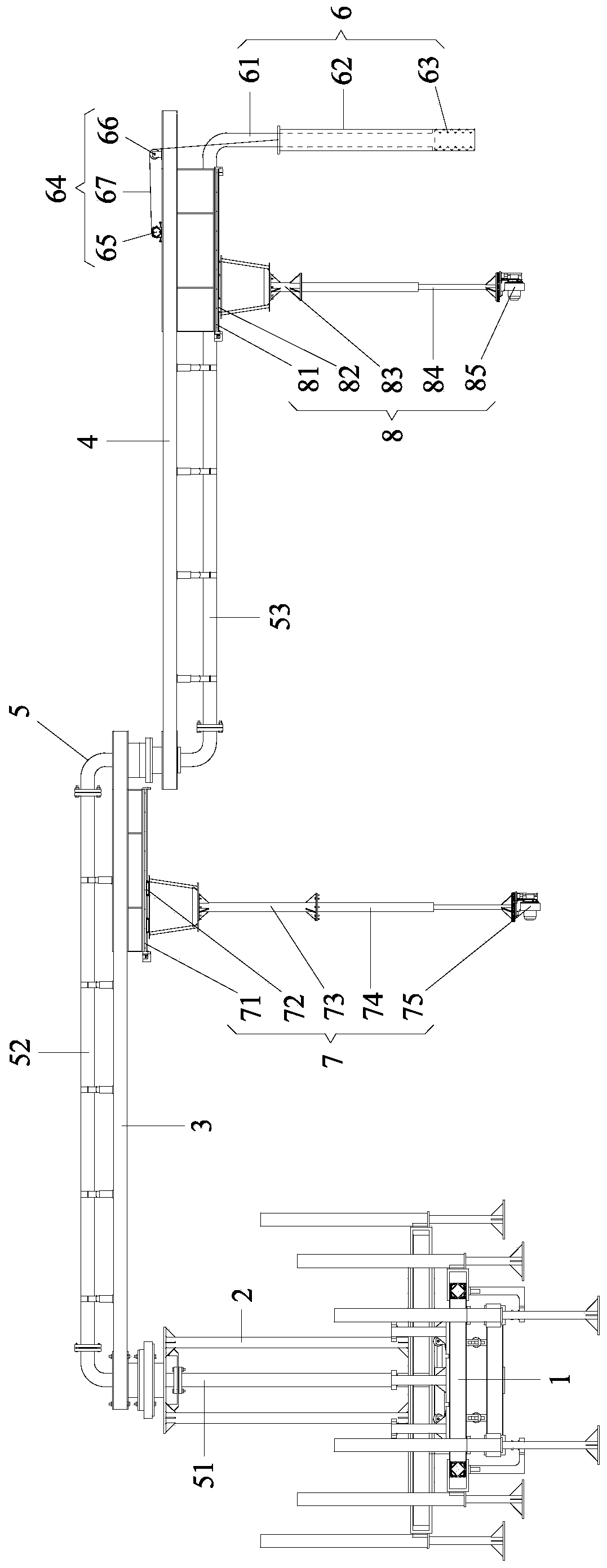

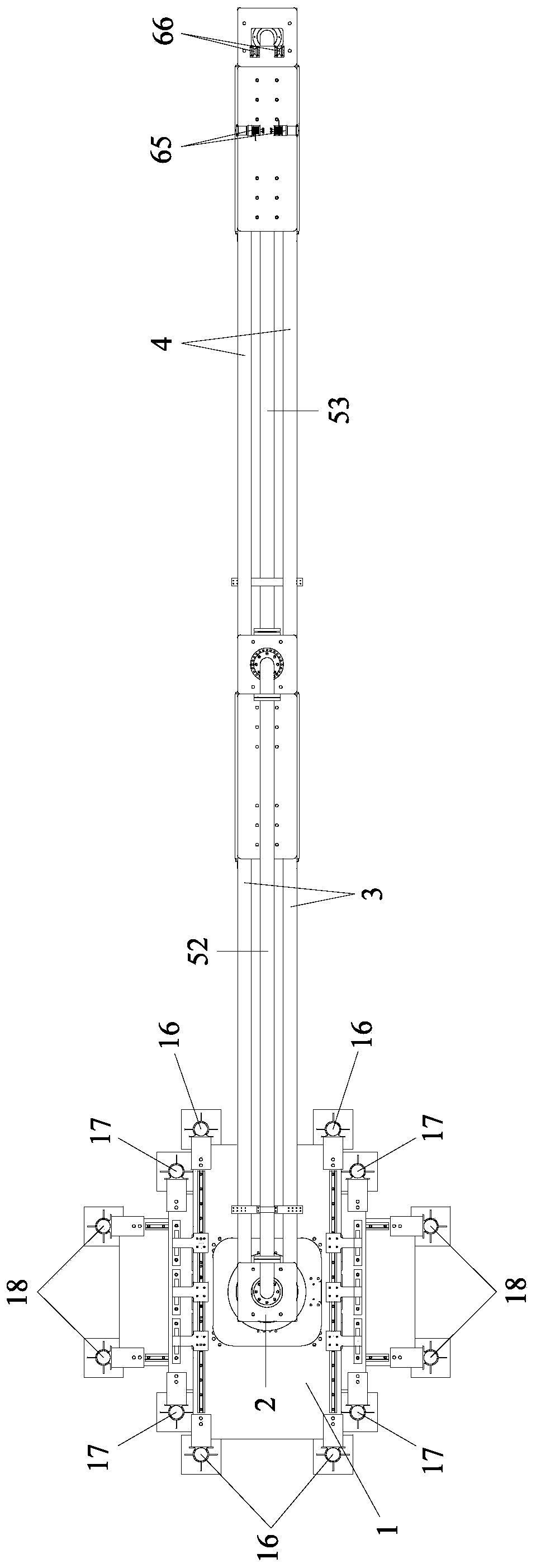

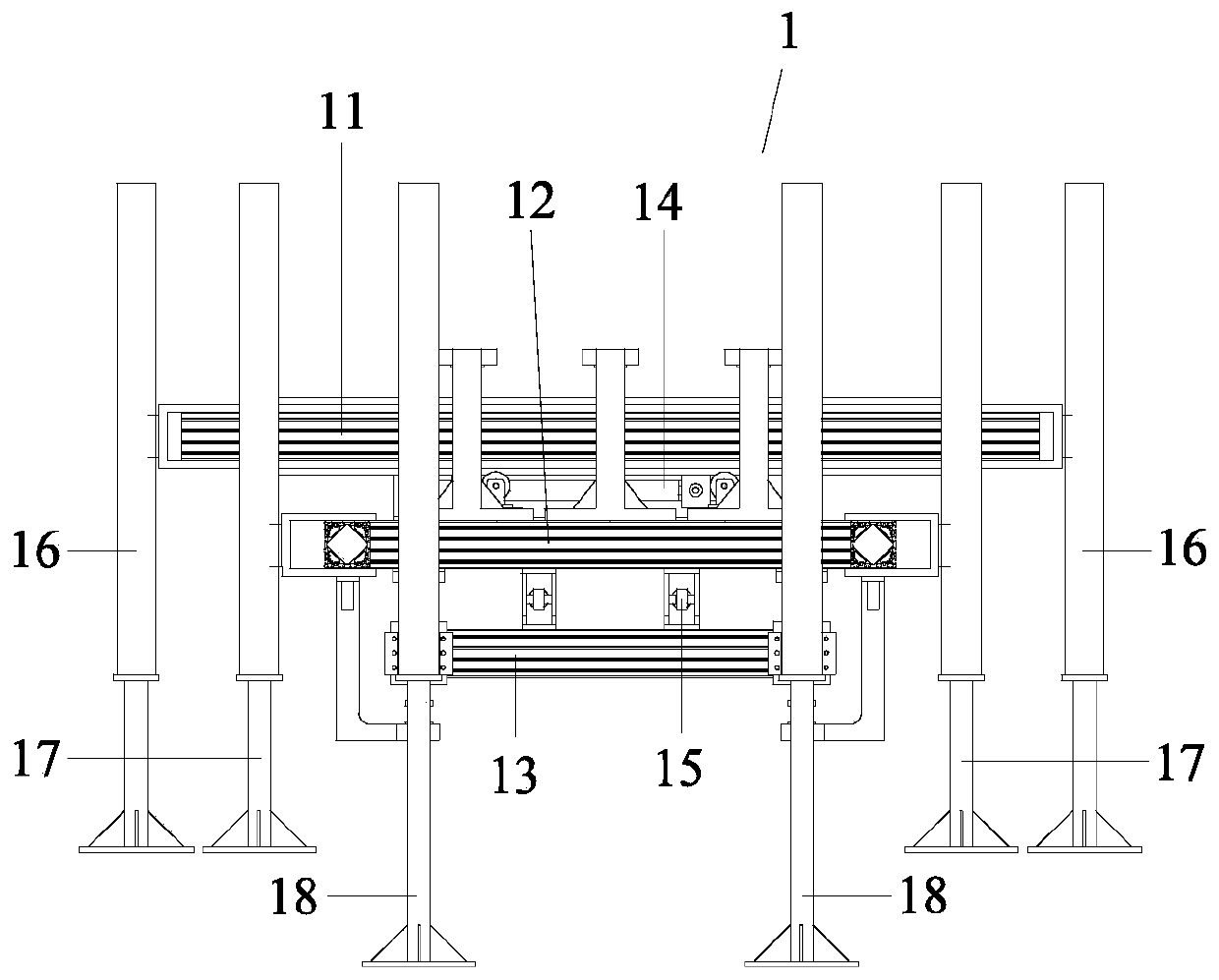

[0043] Such as Figure 1-3 Shown, a kind of concrete distribution machine of the present invention comprises:

[0044] The walking base 1 is used for lifting and walking of the concrete placing machine. The walking base 1 includes a top platform 11, a middle platform 12 and a bottom platform 13 arranged in sequence from top to bottom. The top platform 11, the middle platform 12 and the bottom platform 13 are rectangular plates, the bottom platform 13 is provided with a first sliding part and a first driving part 15, the first sliding part is connected to the bottom of the middle platform 12, the first The driving part 15 is used to drive the middle platform 12 to slide along the first sliding part in the horizontal plane, the middle platform 12 is provided with a second sliding part and a second driving part 14, and the second sliding part is connected to At the bottom of the top platform 11, the second driving part 14 is used to drive the top platform 11 to slide along the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com