Pneumatic type jet flow washing and sucking desilting system for hydropower station overhauling gate groove

An overhaul gate, pneumatic technology, applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of high energy consumption and low efficiency of airlift dredging devices, and achieve large area, good dredging effect and high efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to facilitate the understanding and implementation of the present invention by those of ordinary skill in the art, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the embodiments described herein are only used to illustrate and explain the present invention, but not to limit it. this invention.

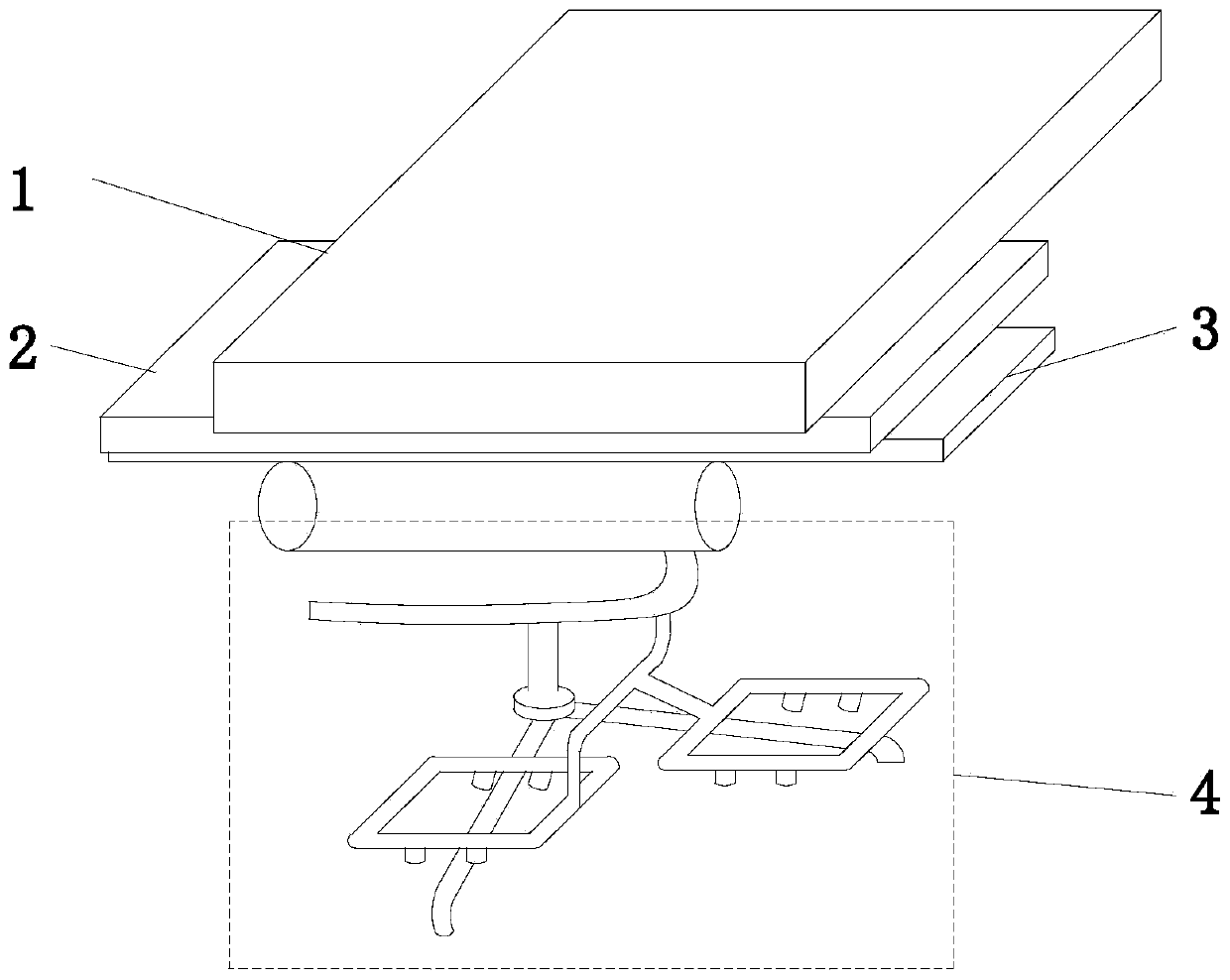

[0036] figure 1 Shown is the overall physical diagram of the embodiment of the present invention. A pneumatic jet flushing and silting dredging system for the maintenance gate slot of a hydropower station of the present invention consists of a large shelf 1, a small shelf 2, a slide 3 and a jet flushing and silting dredging system. The device 4 etc. are composed.

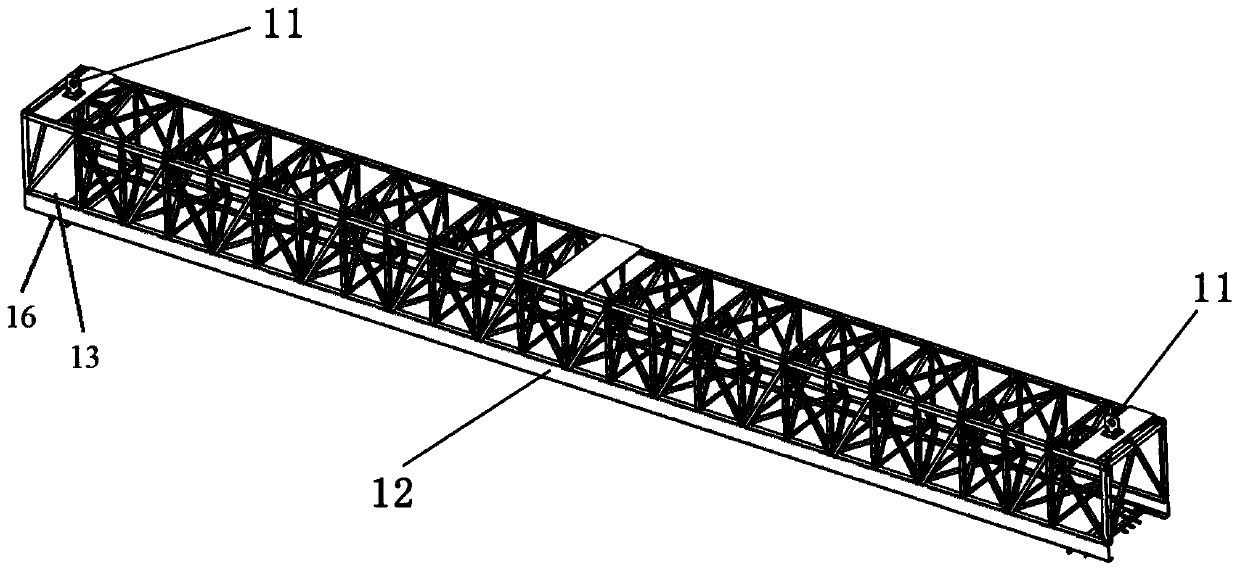

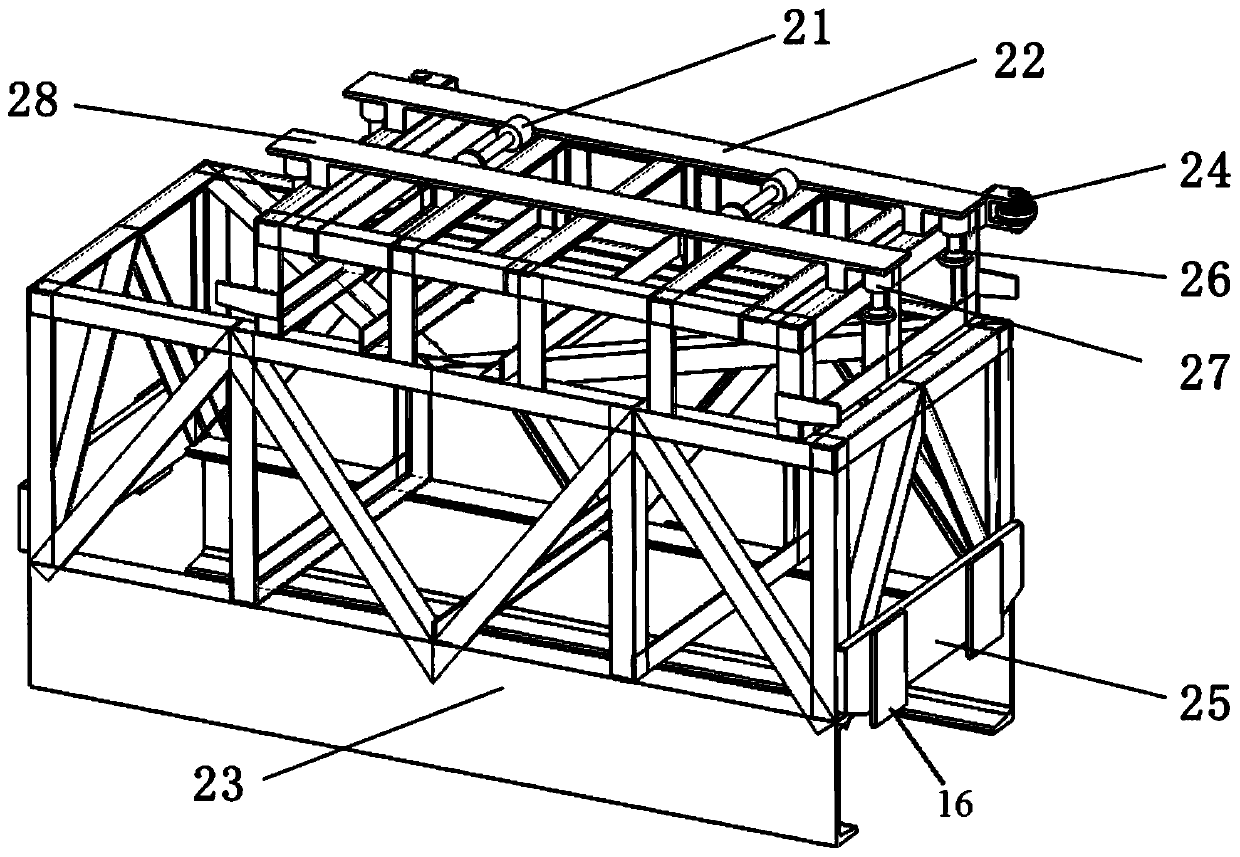

[0037] Large shelf 1 as a carrier, such as figure 2 shown. The large frame 1 is suspended by a crane through the hoisting base 11, and the jet scouring and silt removal device 4 is sent to the underw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com