Textile yarn tension control mechanism and method thereof

A technology of tension control mechanism and thread yarn, which is applied in the textile field, can solve the problems of cumbersome operation, poor flexibility of use, and large space occupied by the control mechanism, and achieve the effect of simple operation and reduced floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

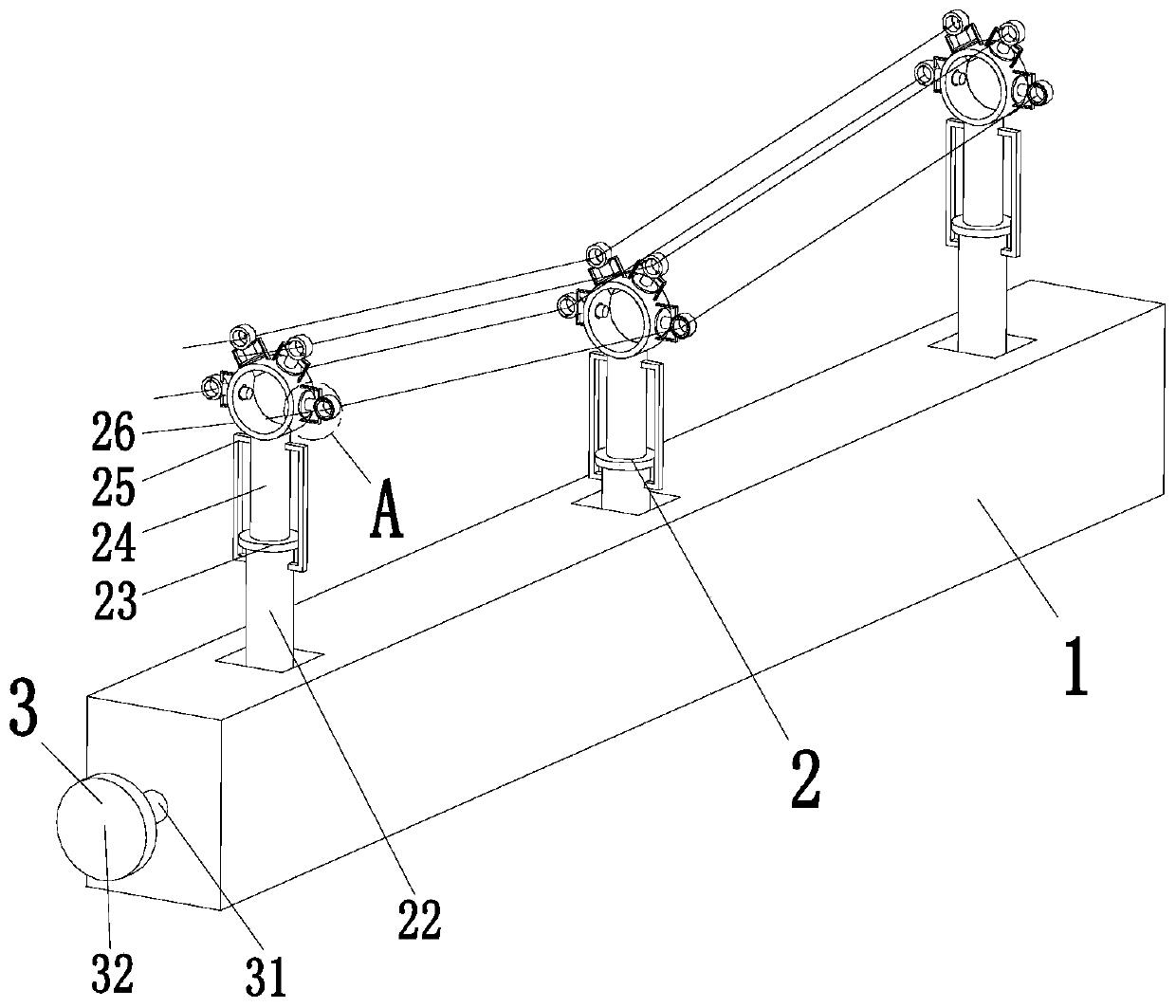

[0050] Embodiment one: if Figure 4 Said, is a state of use of the present invention, according to Figure 4 As shown, the adjusting dial 32 is rotated in the opposite direction, and the adjusting dial 32 drives the adjusting mechanism 33 to work through the adjusting rod 31. Due to the reverse rotation, the control adjusting devices 3 on both sides are lowered, and the control adjusting device 3 in the middle is raised, showing as follows: Figure 6 The usage status shown.

Embodiment 2

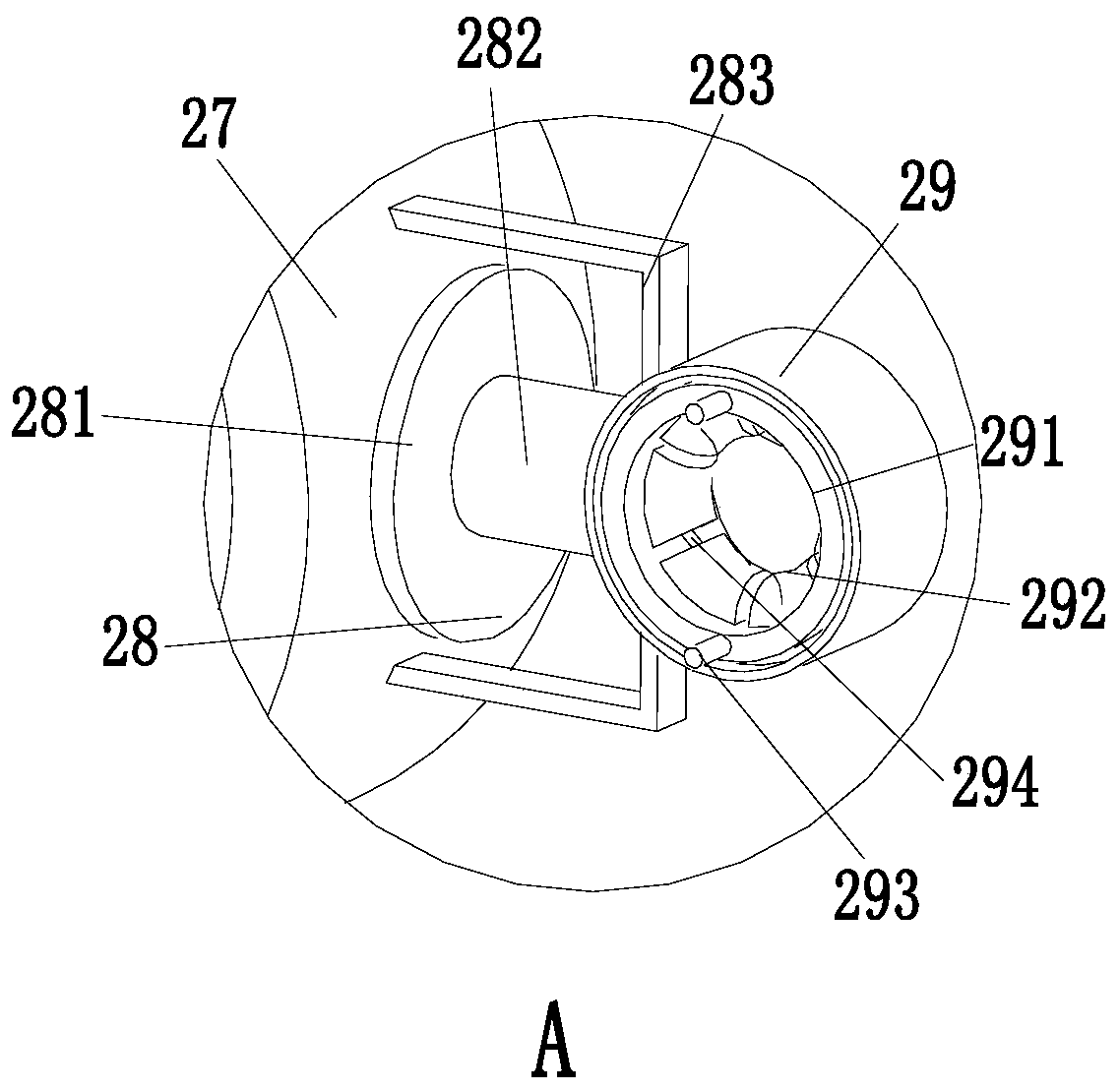

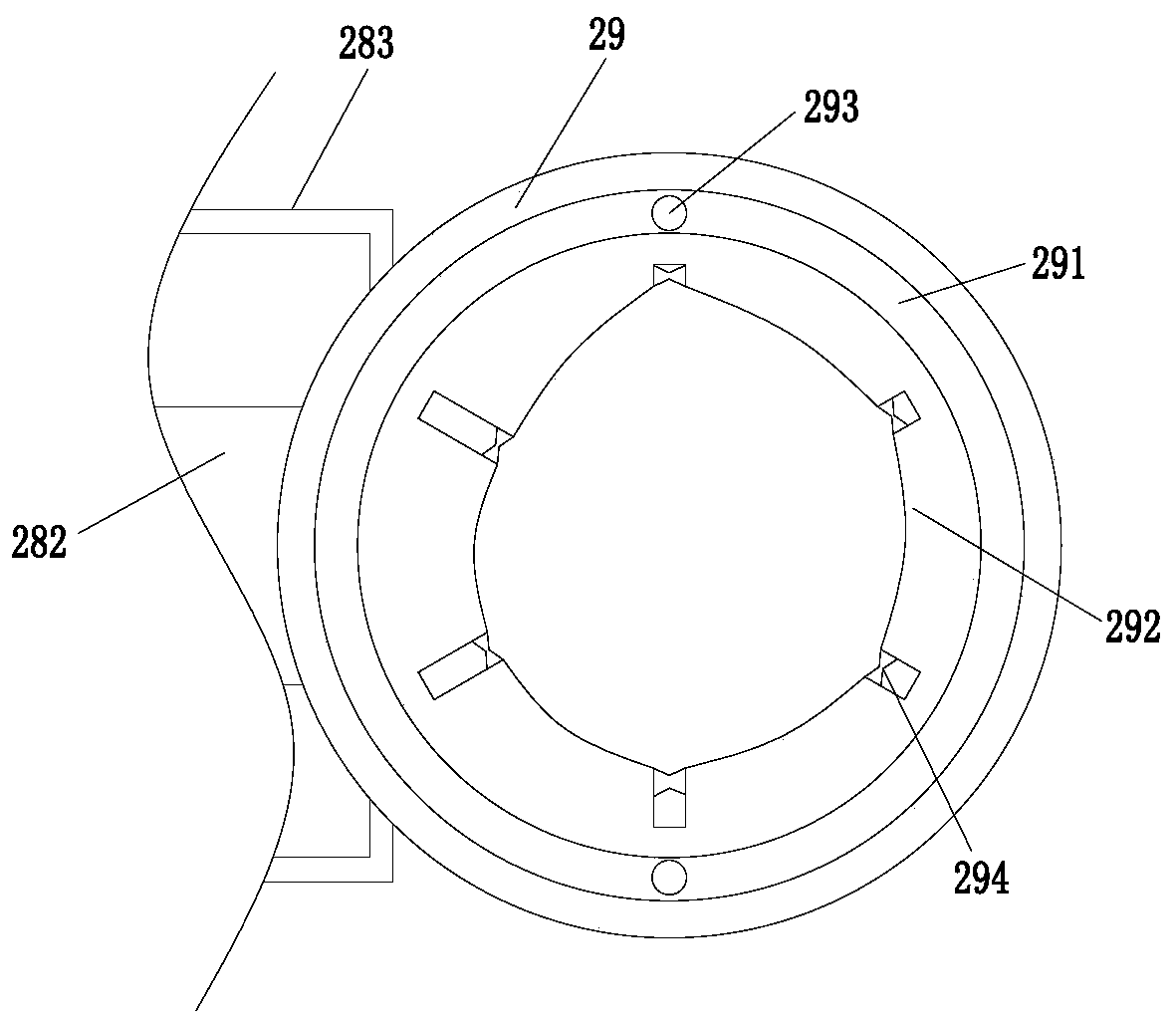

[0051] Embodiment two: according to image 3 As shown, when it is necessary to fine-tune the tension of a single textile yarn, only by rotating the one-way ratchet 291 to drive the support ring 292, the height of the guide wheel 294 supporting the textile yarn can be adjusted, as Figure 7 shown.

[0052] To sum up, the workflow described above realizes the function of controlling the tension of textile yarns, and solves the problem that the single-line and single-control mechanism in textile yarn tension control has a large footprint, inconvenient operation, and multi-control devices cannot be adjusted at the same time. When there are multiple lines, only multiple lines can be adjusted at the same time, the flexibility is poor, and the single-line adjustment requires overall adjustment, the adjustment range is large, and the adjustment accuracy is not high, and the goal has been achieved.

[0053] The present invention is only illustrated with reference to the embodiments sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com