A transportation mechanism of a robot intelligent production line

A robot intelligence and production line technology, applied in the field of transportation, can solve problems such as simple functions, difficult to meet the needs of conveyor belt transportation in different directions, and troublesome adjustment of the height and level of transportation mechanisms, so as to achieve low production costs, improve reliability and stability, fully functional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

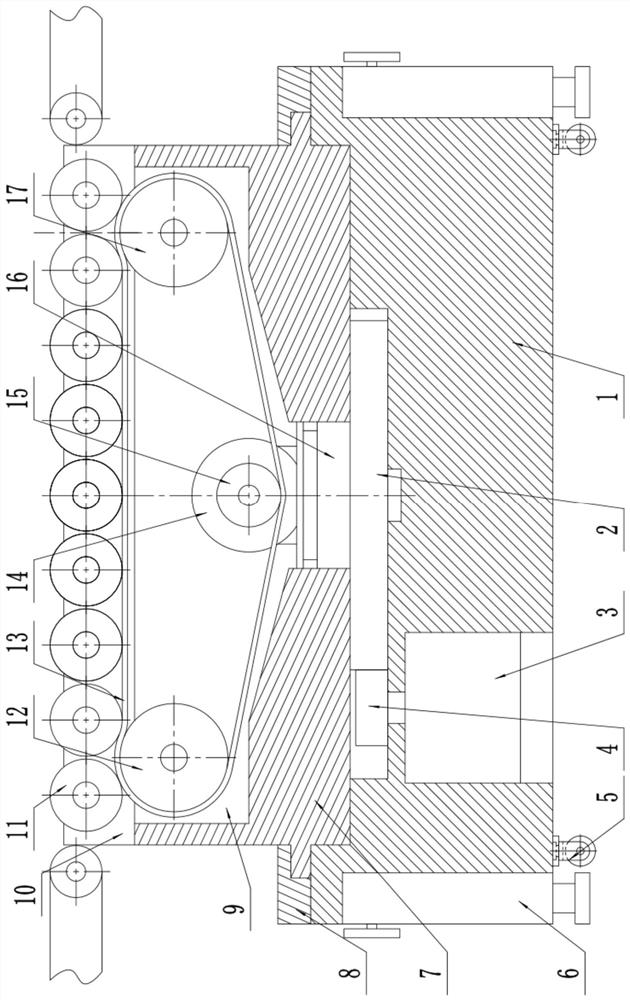

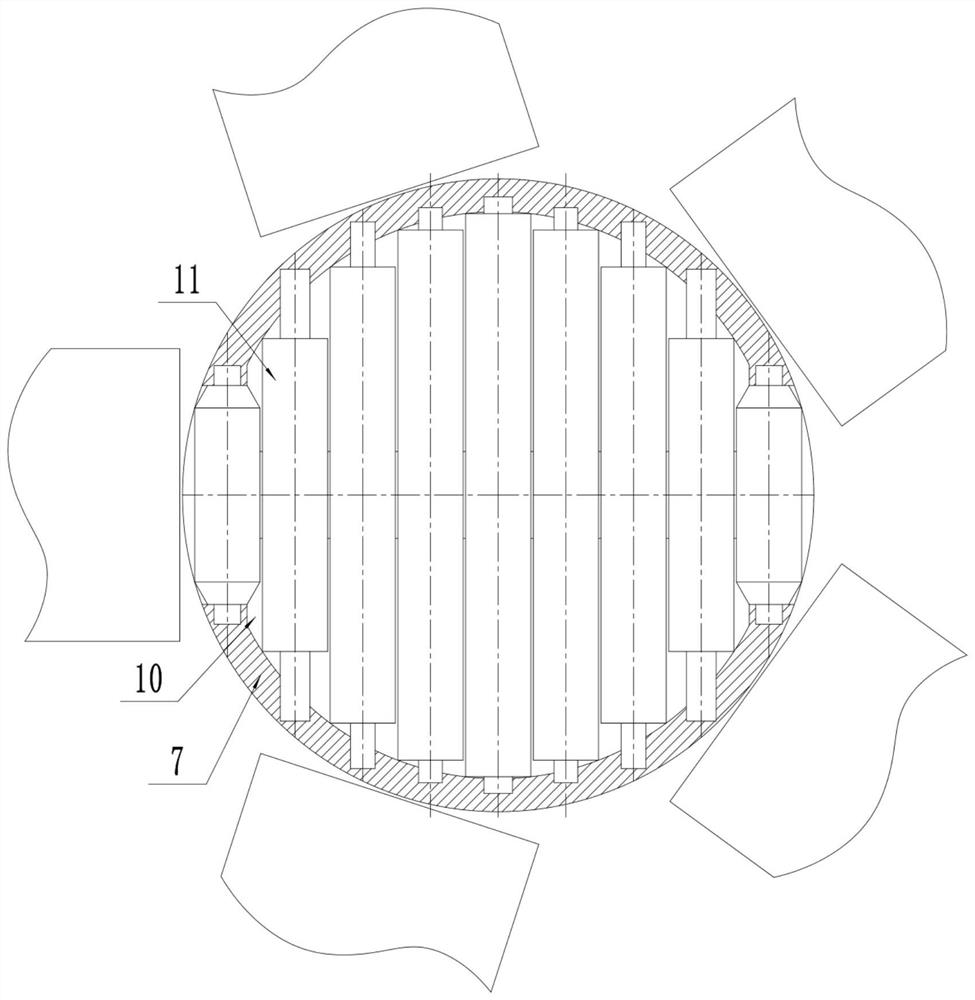

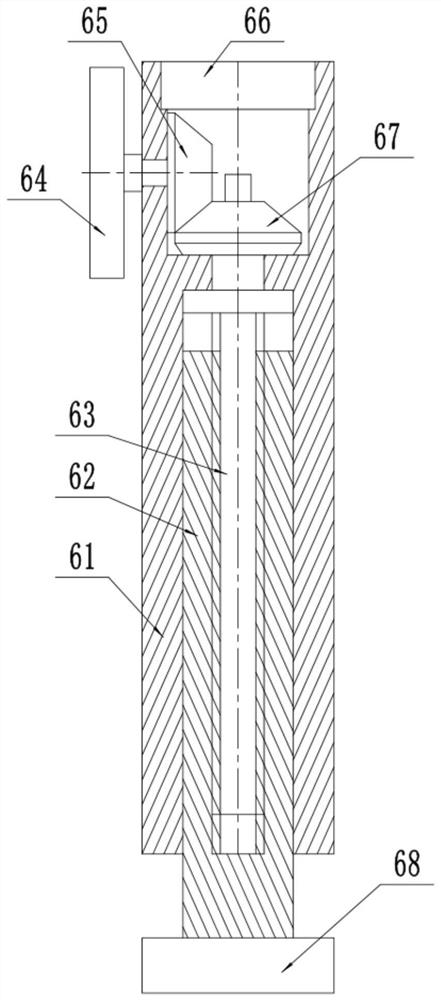

[0024] Such as figure 1 and figure 2 As shown, this specific embodiment adopts the following technical solutions: a transportation mechanism for a robot intelligent production line, including a base 1, a driven gear 2, a motor 3, a driving gear 4, a universal wheel 5, a support adjustment device 6, and a movable seat 7. Fixed ring body 8, inner groove 9, groove body 10, transport roller 11, driven pulley 1 12, driving belt 13, motor 2 14, driving pulley 15, tensioning device 16 and driven pulley 2 17. The bottom four corners of the base 1 are fixedly connected with universal wheels 5; the motor one 3 is fixedly connected inside the left side of the base 1, and the upper output shaft end of the motor one 3 is fixedly connected with a driving gear 4; There are four support adjustment devices 6, and the support adjustment devices 6 are respectively fixedly connected to the front and rear positions on the left and right sides of the base 1; In the groove, the center of the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com