Rapid disassembling and assembling structure for unmanned aerial vehicle vertical flat tail connection

A technology of vertical tail and unmanned aerial vehicles, applied in the field of unmanned aerial vehicles, can solve the problems of cumbersome installation process and long time, and achieve the effect of simple structure, few structural parts, and short withdrawal or deployment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] This embodiment is a quick disassembly structure for connecting the vertical and horizontal tails of the drone.

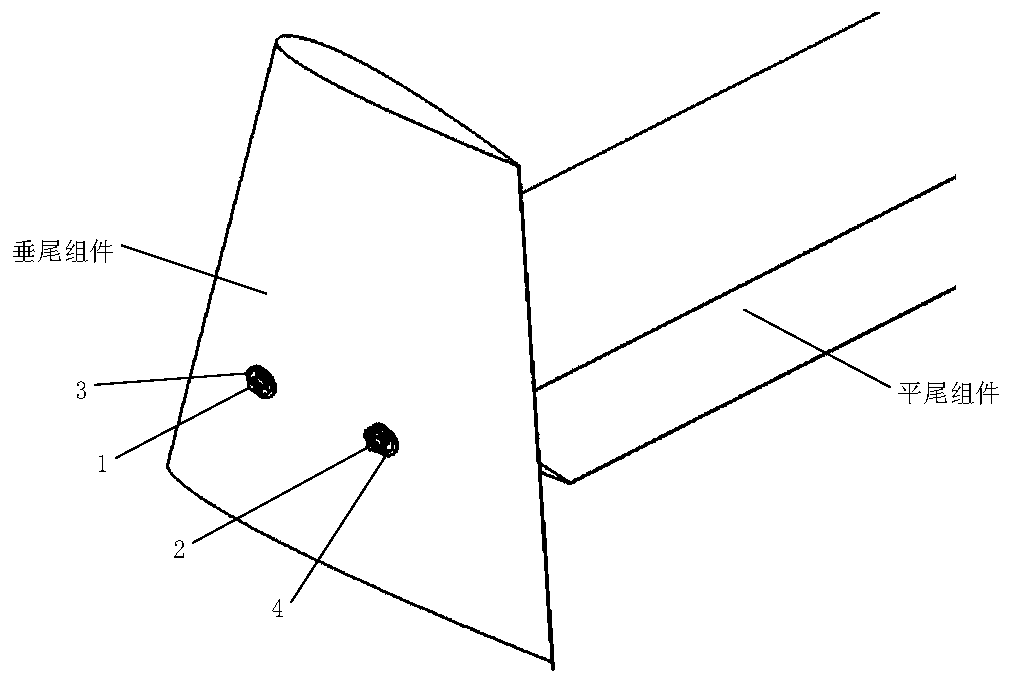

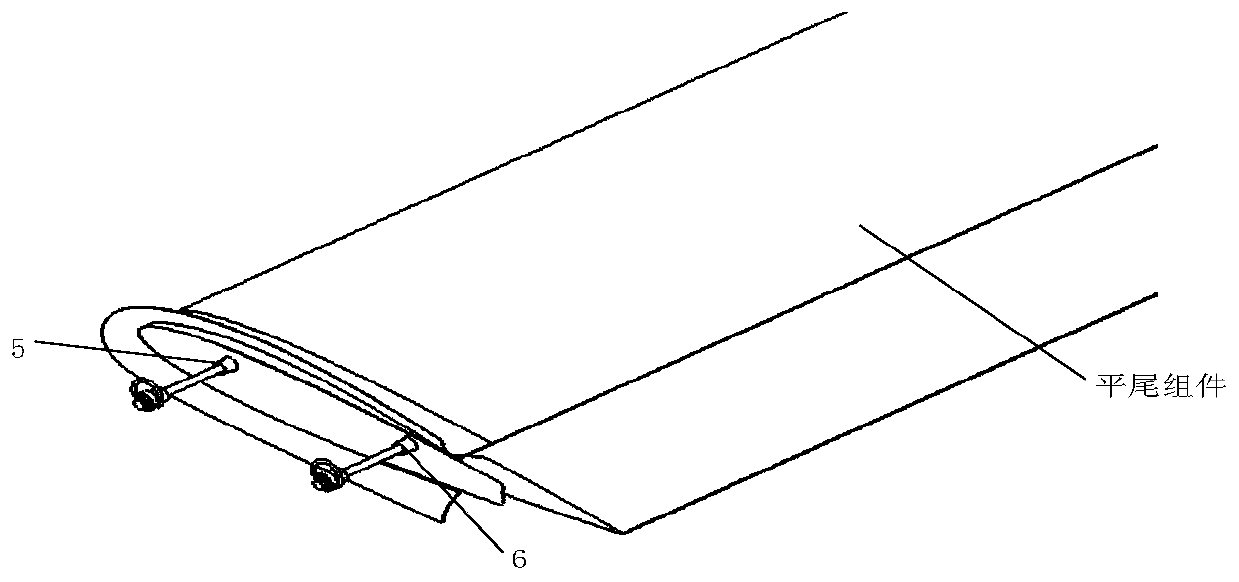

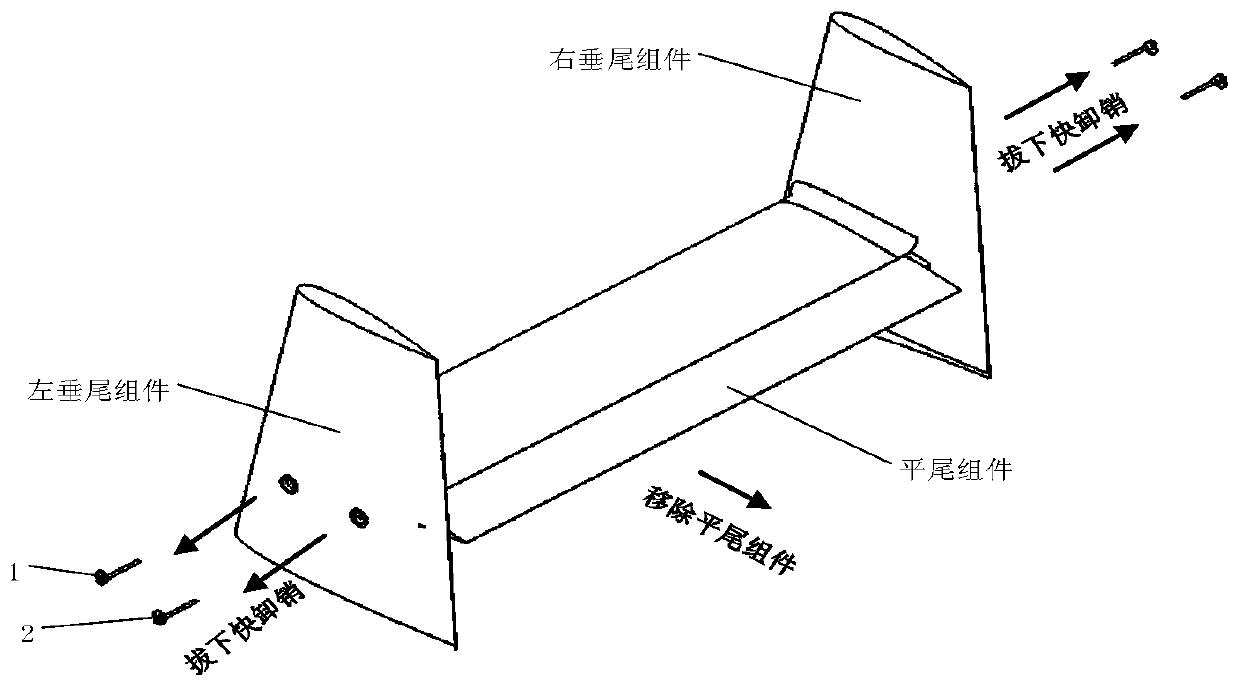

[0016] refer to Figure 1 ~ Figure 3 , the present embodiment relates to a quick disassembly structure of the horizontal tail and the vertical tail of the UAV, and the fast disassembly and assembly of the horizontal tail and the vertical tail of the UAV connected by the docking mount and the quick release pin. The quick disassembly and assembly structure of the vertical and horizontal tail connection of the UAV consists of the horizontal tail assembly, the vertical tail assembly and the front connection quick release pin 1, the rear connection quick release pin 2, the vertical tail front connection seat 3, the vertical tail rear connection seat 4, and the horizontal tail front connection Seat 5, connecting seat 6 form after flat tail. The horizontal tail assembly is located between the two vertical tail assemblies; the two ends of the horizontal tail assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com