Plastic bottle transverse type puncture compression mechanism and plastic bottle puncture compression recycling machine

A compression mechanism and plastic bottle technology, applied in the field of environmental protection, can solve the problems of small bottle force, small compression degree, easy deformation and rebound, etc., to improve compression efficiency and compression degree, avoid movement track deviation, and facilitate puncture and the effect of compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

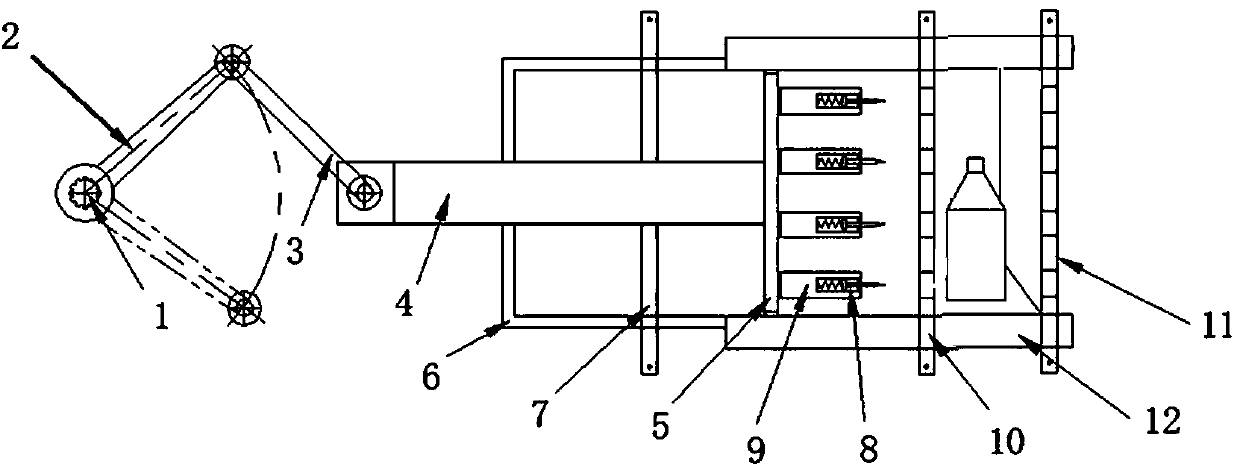

[0027] The technical solutions of the present invention will be further described below through specific implementation manners in conjunction with the accompanying drawings.

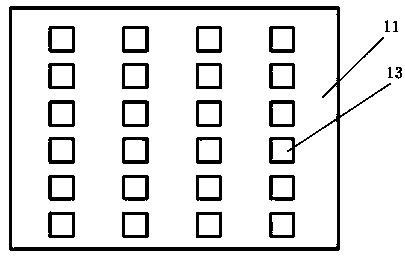

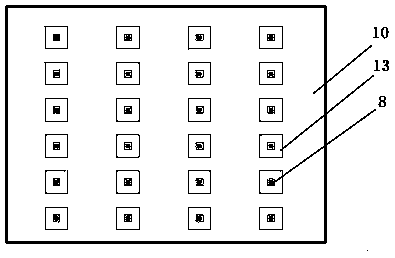

[0028] As shown in the figure, a horizontal puncture compression mechanism for a plastic bottle recycling machine includes a compression box 12, a propulsion device, and a puncture extrusion device. The upper part of the compression box 12 is provided with a material inlet, and the lower part is provided with a recycling A shelf is set above the recovery port. The compression box 12 includes a box frame and a box shell. The box frame is welded by angle steel, and the box shell is welded by sheet metal bending. The compression box 12 A front baffle 10 and a rear baffle 11 are arranged inside, and the board surfaces of the front baffle 10 and the rear baffle 11 are arranged oppositely, and a gap connecting the material inlet and the recovery port is formed between the front baffle 10 and the rear baffle 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com