Actuating cam type lubricating self-cleaning mechanism

A cam-type, self-cleaning technology, which is applied in gear lubrication/cooling, manipulators, manufacturing tools, etc., can solve the problem of robot penetration of grease and other problems, and achieve the effects of small rotation resistance, oil leakage prevention, and stable internal pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

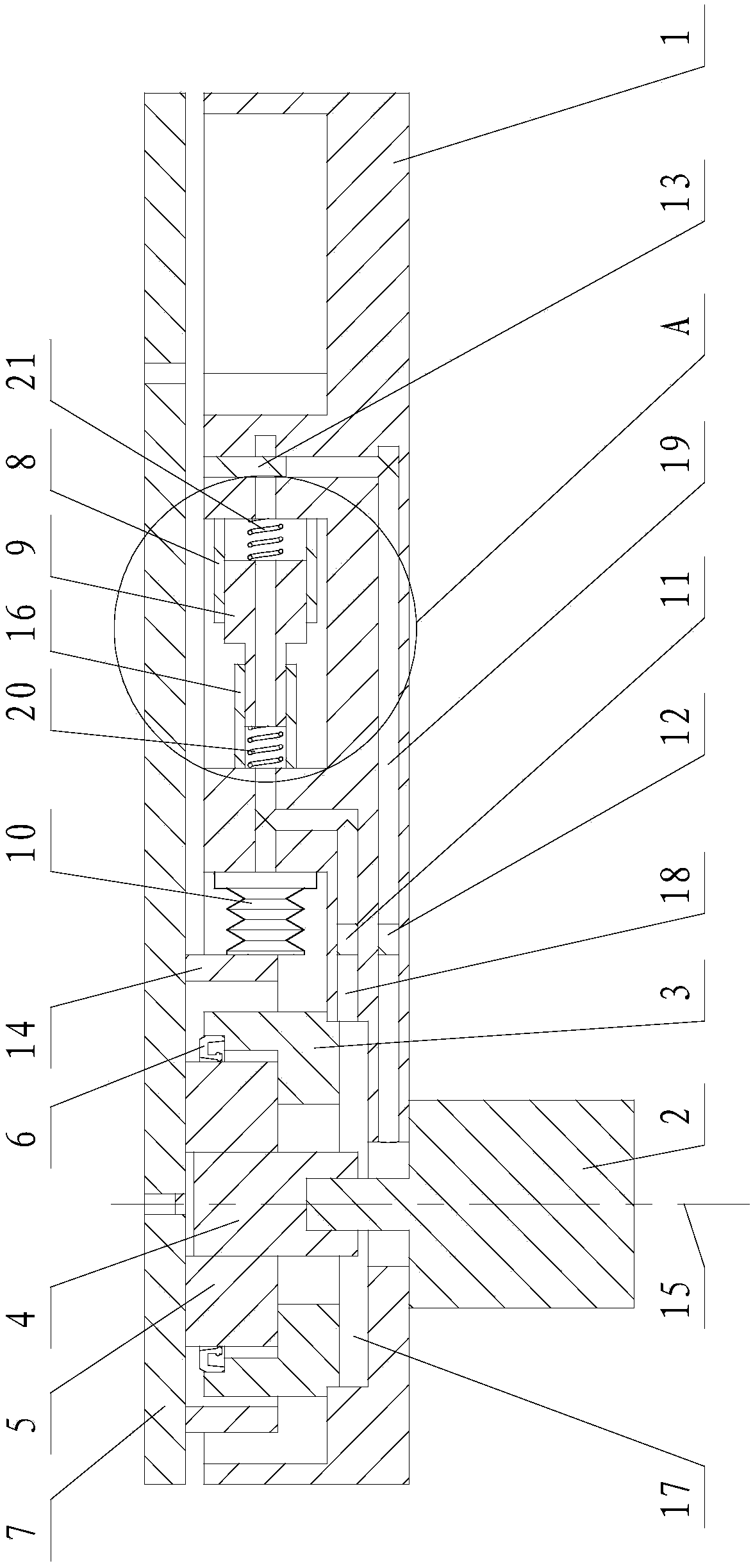

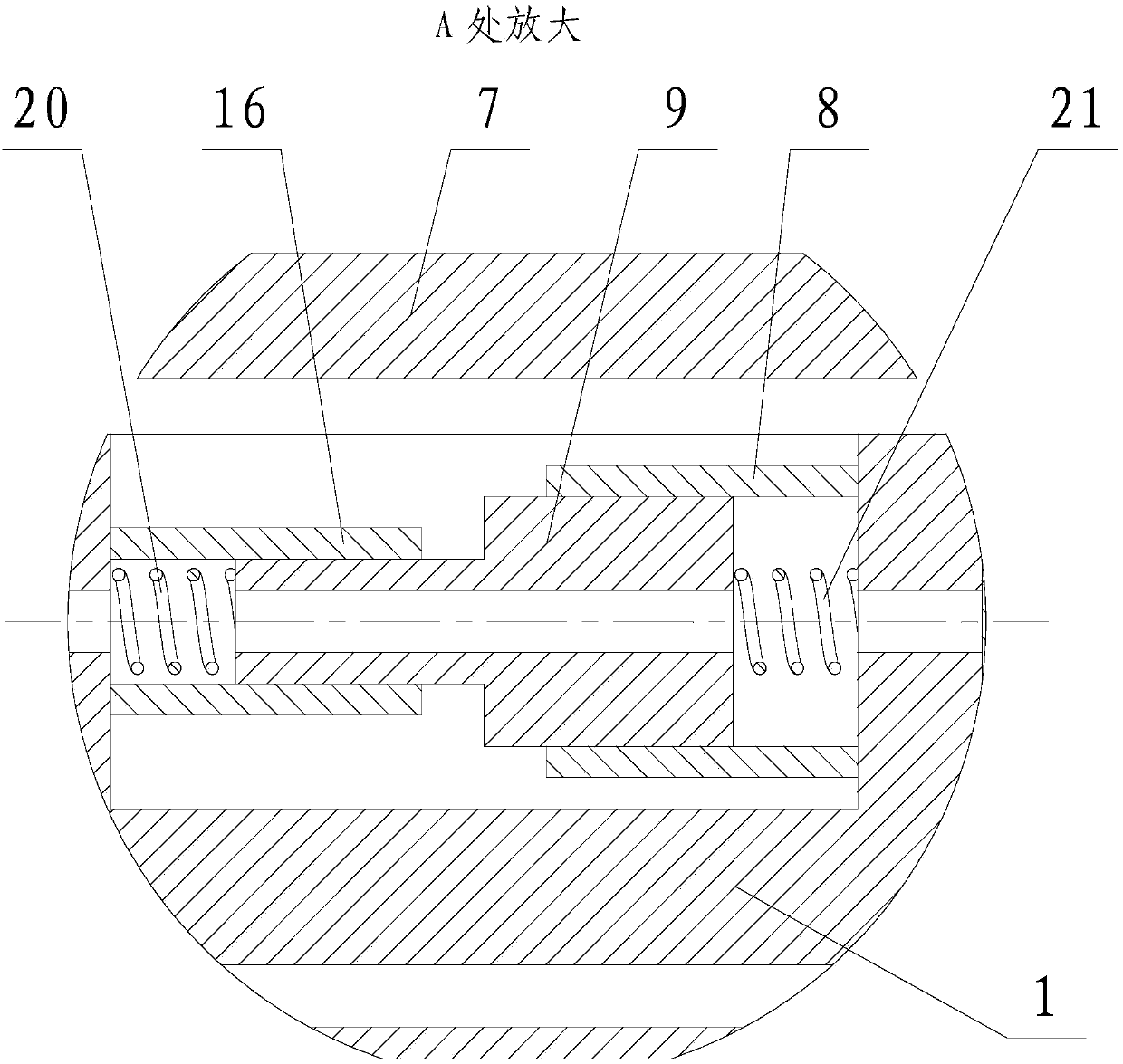

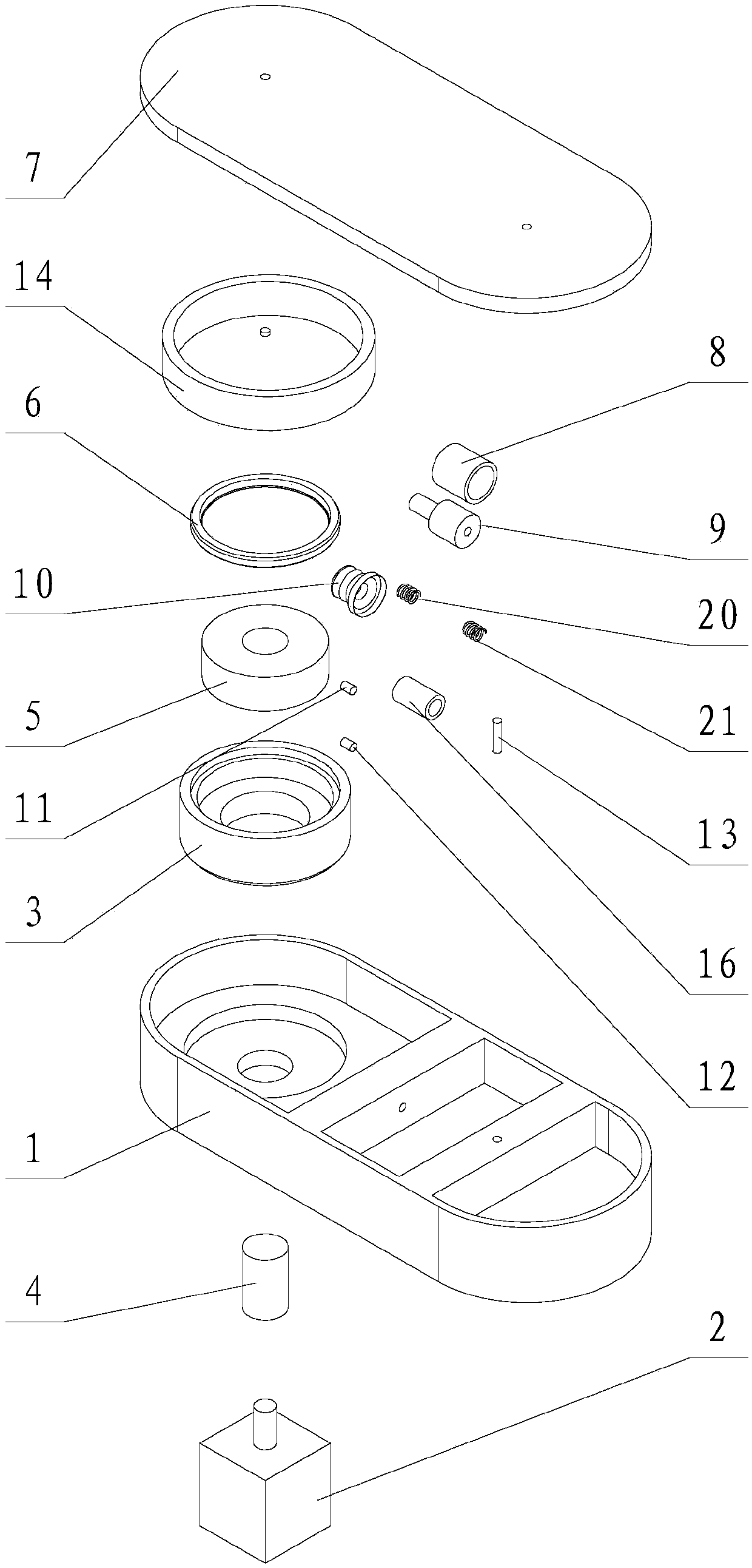

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0020] Such as Figure 1~3 As shown, the present invention includes a boom 1, a small arm 7, a motor 2 and a reducer housing 3 respectively accommodated in the boom 1, a reducer input gear shaft 4, a reducer output shaft 5, an inertial double-headed piston mechanism, Oil outlet one-way valve 11, oil return one-way valve 12 and filter element 13, in which the motor 2 is statically sealed and fixedly connected to the boom 1, the output end penetrates into the boom 1, and the gear shaft 4 is input through the reducer and the output of the reducer One end of the shaft 5 is connected, one end of the reducer casing 3 is statically sealed and fixedly connected in the boom 1, and the other end is connected with the output shaft 5 of the reducer through a rotating dynamic seal 6, and the other end of the reducer casing 3 is connected to the reducer The machine input ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com