Automatic blender mixer

A mixer, automatic technology, used in mixers, shaking/oscillating/vibrating mixers, dissolving and other directions, can solve the problems of low mixing efficiency and poor effect, and achieve good mixing effect, high efficiency, and protection of physical and mental health. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

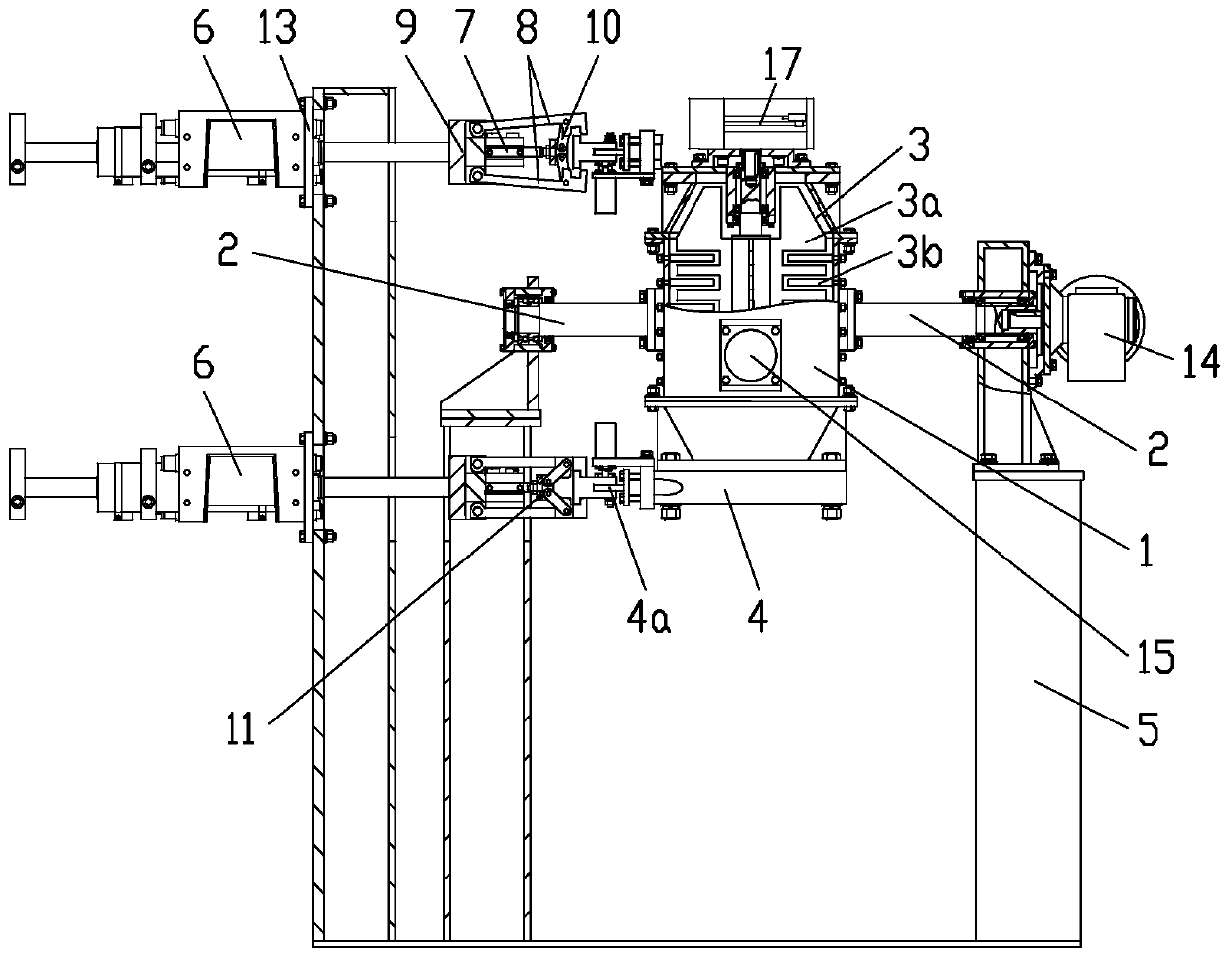

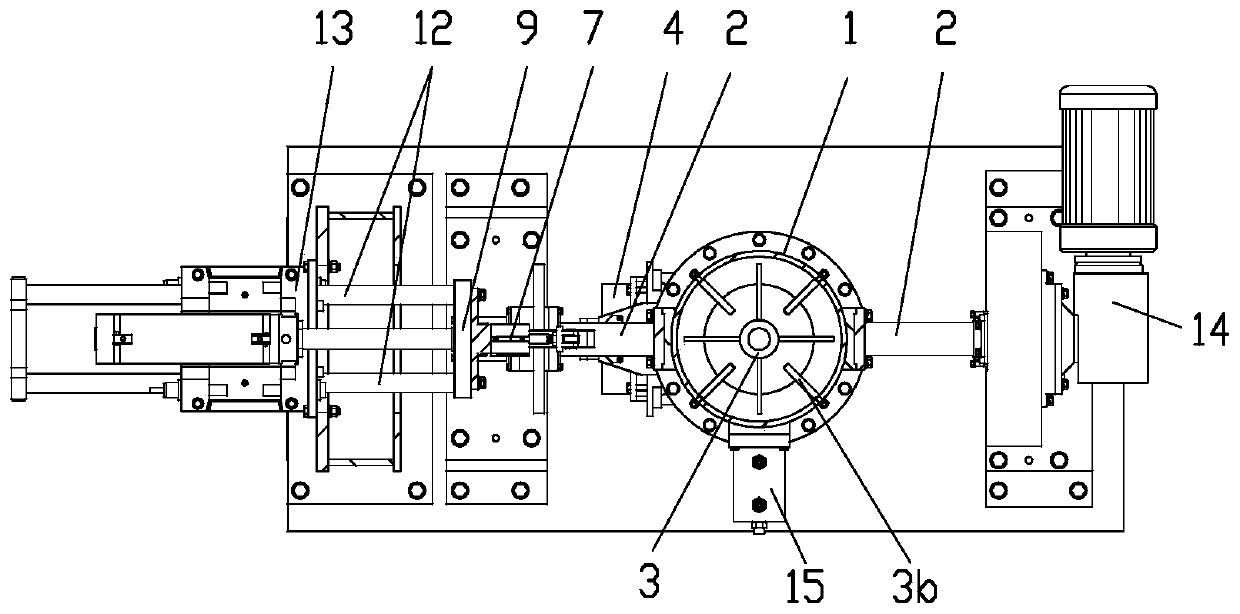

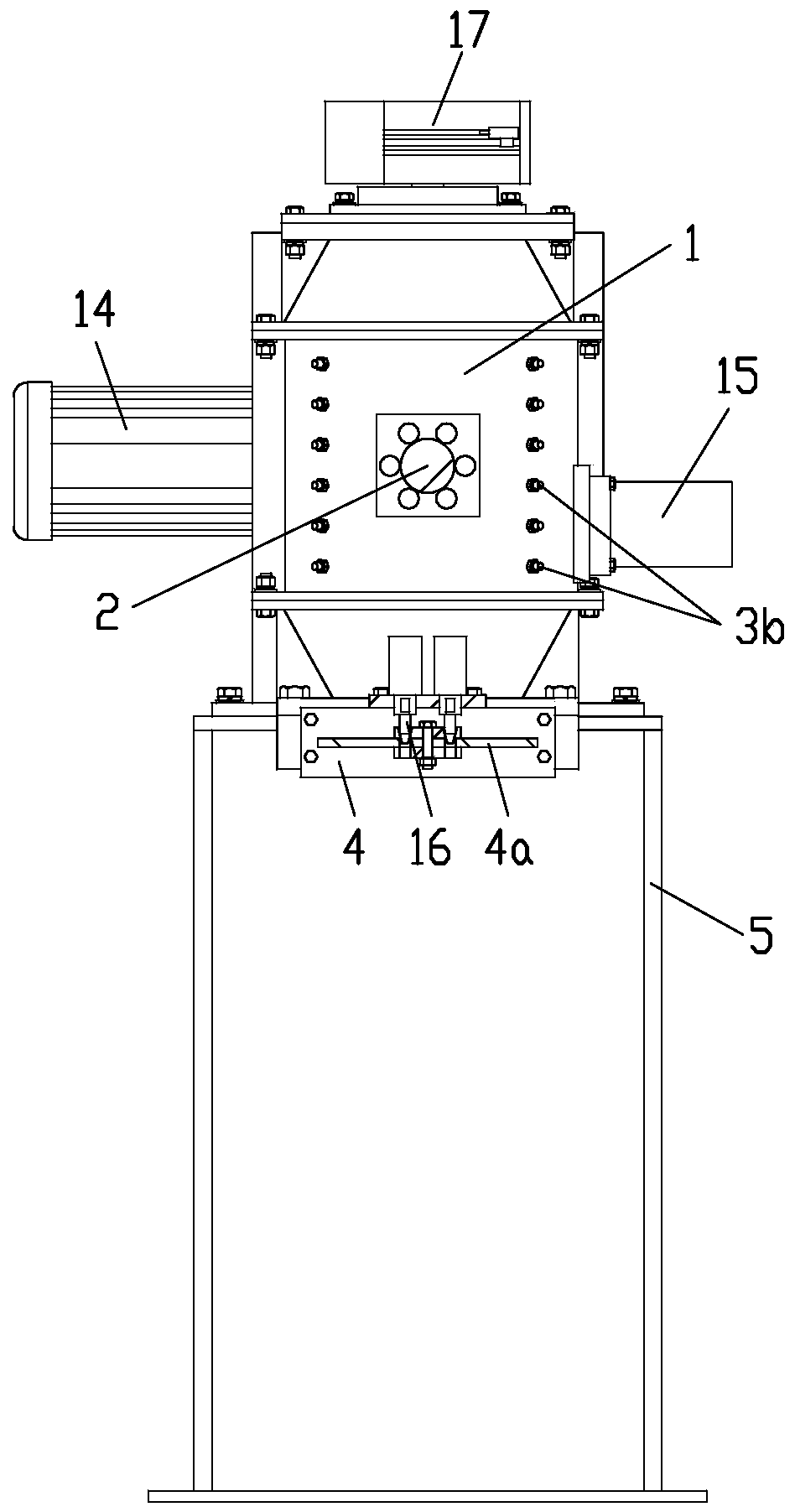

[0022] see figure 1 , figure 2 , image 3 , an automatic mixing machine, comprising a mixing tank 1 with a closed mouth, the mixing tank 1 is supported by two semi-shafts 2 arranged on the side wall of the tank and driven to rotate by a reduction motor 14; the inside of the mixing tank 1 A stirring paddle 3 is provided, and the stirring paddle 3 is driven by a rotating cylinder 17 provided at the bottom of the mixing tank 1 to swing at 180 degrees;

[0023] Wherein, the stirring blade 3 is provided with a stirring blade 3a, and the inner wall of the mixing tank 1 is provided with a fixed blade 3b, and the stirring blade 3a has a gap for avoiding the fixed blade 3b. The fixed blade 3b can be a sheet structure, a plate structure or a columnar structure. In this implementation, a colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com