Package substrate, semiconductor device and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in the direction of semiconductor devices, electric solid devices, electrical components, etc., can solve problems such as the inability of the white glue layer to adapt, loss of displacement ability, and cracking, so as to improve adaptability, delay cracking time, and relieve heat. The effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

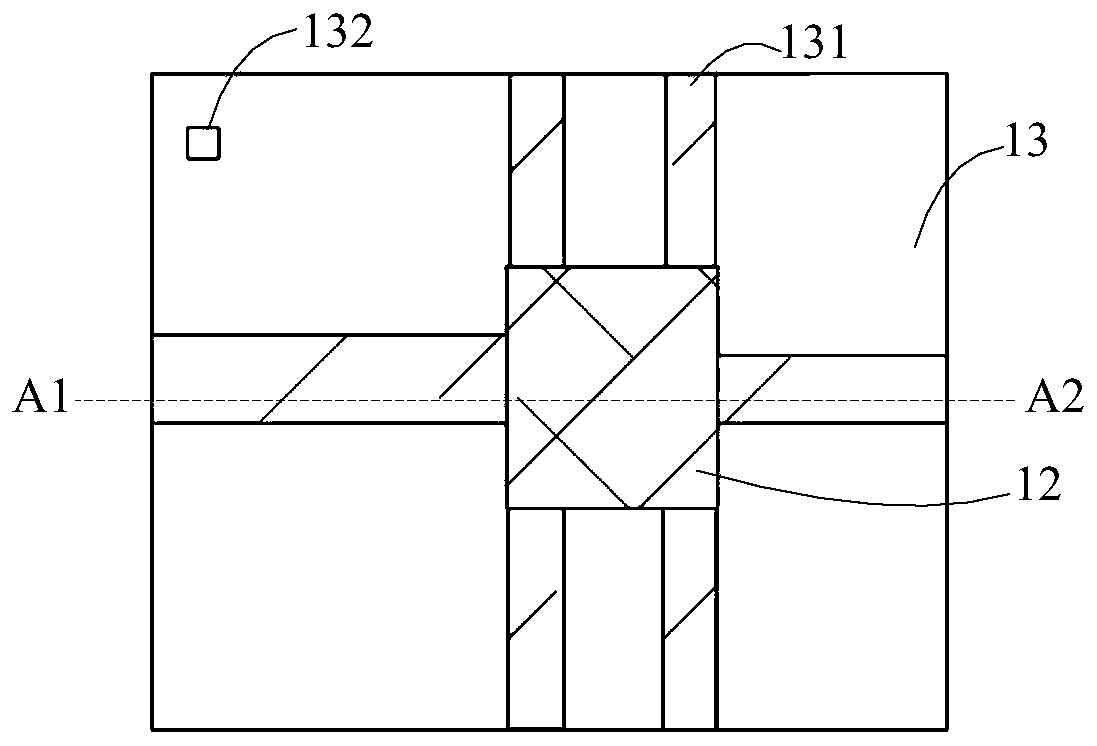

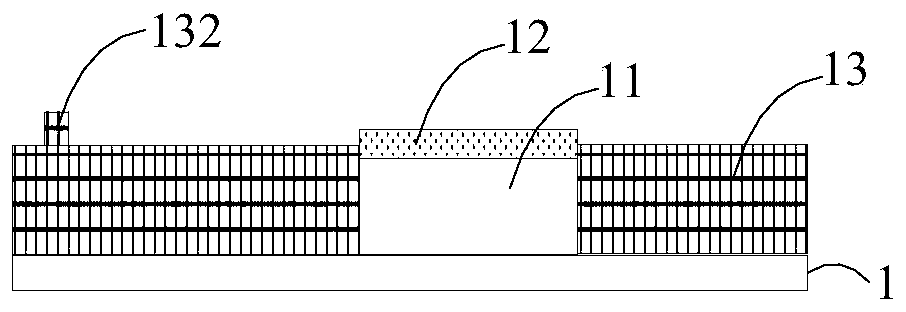

[0040] See figure 1 , is a top view of a semiconductor device according to Embodiment 1 of the present invention.

[0041] Such as figure 1 and figure 2 As shown, this semiconductor device includes: a crystal-bonding substrate 1, an LED chip 11 disposed on the crystal-bonding substrate 1, a fluorescent sheet 12 disposed on the LED chip 11, and a fluorescent sheet 12 disposed on the LED chip 11 and the fluorescent sheet 12. White glue layer 13 around; wherein, the top of white glue layer 13 is flush with the upper surface of fluorescent sheet 12, and the upper surface of white glue layer 13 is provided with at least one groove 131, and this at least one groove 131 runs through white glue On the inner wall and the outer wall of the layer 13 , the groove extension direction of at least one groove 131 is perpendicular to the side of the LED chip 11 .

[0042] Compared with the prior art, in the semiconductor device of the present invention, since the upper surface of the white...

Embodiment 2

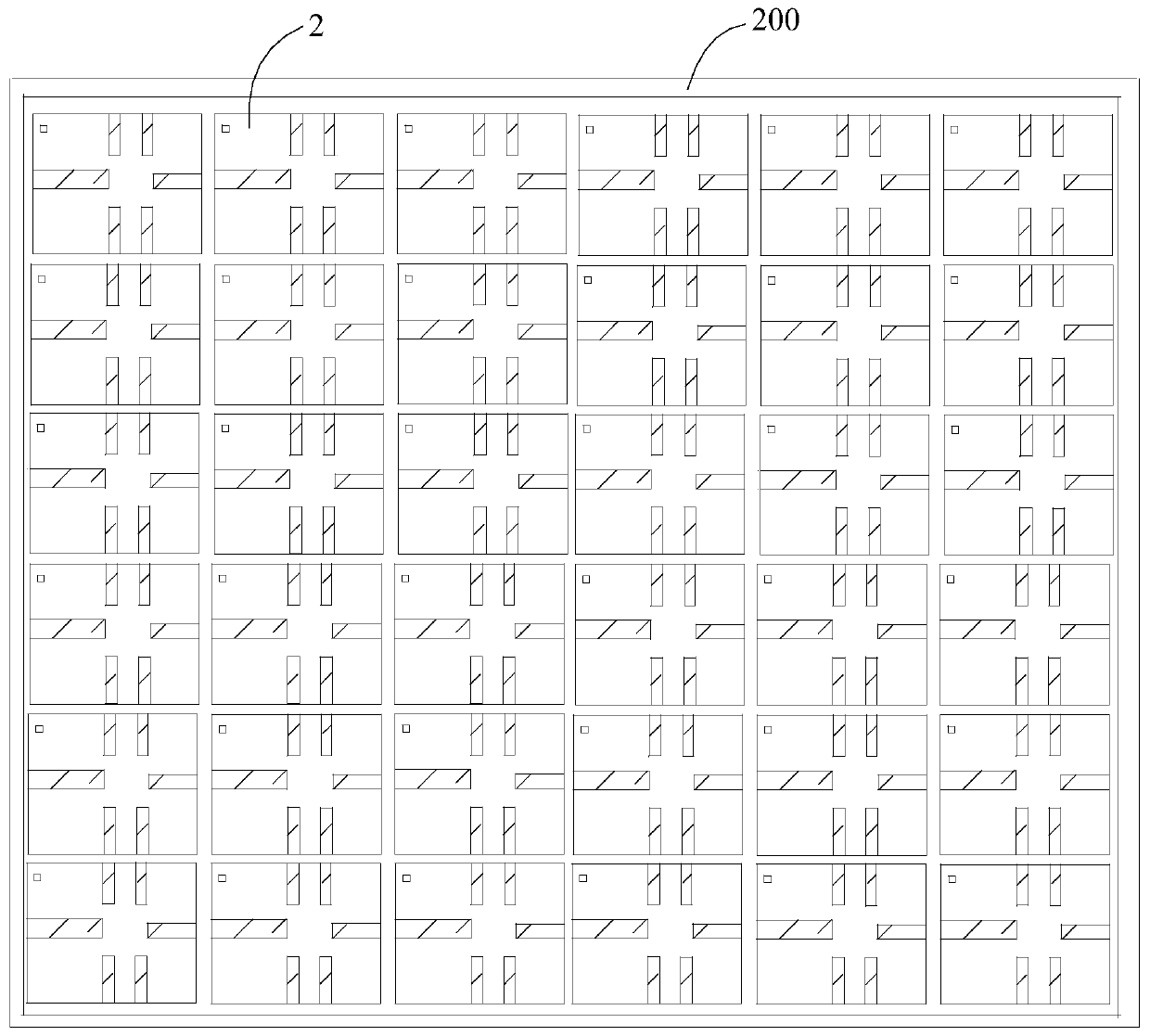

[0048] Such as Figure 3 ~ Figure 5 As shown, the present invention also provides a packaging substrate, which includes: a temporary substrate 200 and a die-bonding substrate 100; wherein, the temporary substrate 100 has a die-bonding area 2, and the die-bonding 2 is arranged at a preset distance and is provided with at least A convex strip 21 and a first through hole 22, one end of at least one convex strip 21 surrounds the fluorescent sheet mounting area 23, and the other end is connected to the edge of the crystal bonding area 2; the crystal bonding substrate 100 is used to fix LEDs at a preset distance Chip 11; when the temporary substrate 200 and the crystal-bonding substrate 100 are aligned and attached, the LED chip 11 fixed on the crystal-bonding substrate 100 is bonded one-to-one with the fluorescent sheet arranged in the fluorescent sheet mounting area 23; After the white glue is injected between the combined temporary substrate 200 and the die-bonding substrate 100,...

Embodiment 3

[0051] The present invention also provides a method for manufacturing a semiconductor device, the following in conjunction with the attached Figure 3 ~ Figure 5 , to describe the preparation method in detail.

[0052] The manufacturing method of the semiconductor device comprises the following steps:

[0053] S1, provide a temporary substrate (such as Figure 6 a); where, if image 3 and Figure 4 As shown, the temporary substrate 200 has a crystal-bonding area 2, the crystal-bonding area 2 is arranged at a preset interval and is provided with at least one convex strip 21 and a first through hole 22, and one end of the at least one convex strip 21 is surrounded by a The fluorescent sheet installation area 23, the other end is connected with the edge of the crystal bonding area 2;

[0054] S2. Use double-sided tape to paste the fluorescent sheet in the fluorescent sheet installation area (such as Figure 6 b);

[0055] Wherein, step S2 includes:

[0056] S21. Provide a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com