Motor and method and mechanism for magnetizing magnetic frame and magnetic strip of motor

A magnetic strip and frame technology, applied in the direction of prefabricated windings embedded in motors, circuits, magnetic objects, etc., can solve the problems of high labor and equipment costs, poor assembly, and high labor costs, reducing labor and equipment transportation, saving labor and equipment cost, the effect of improving the magnetization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the present invention more obvious and understandable, the detailed description is as follows in conjunction with the accompanying drawings.

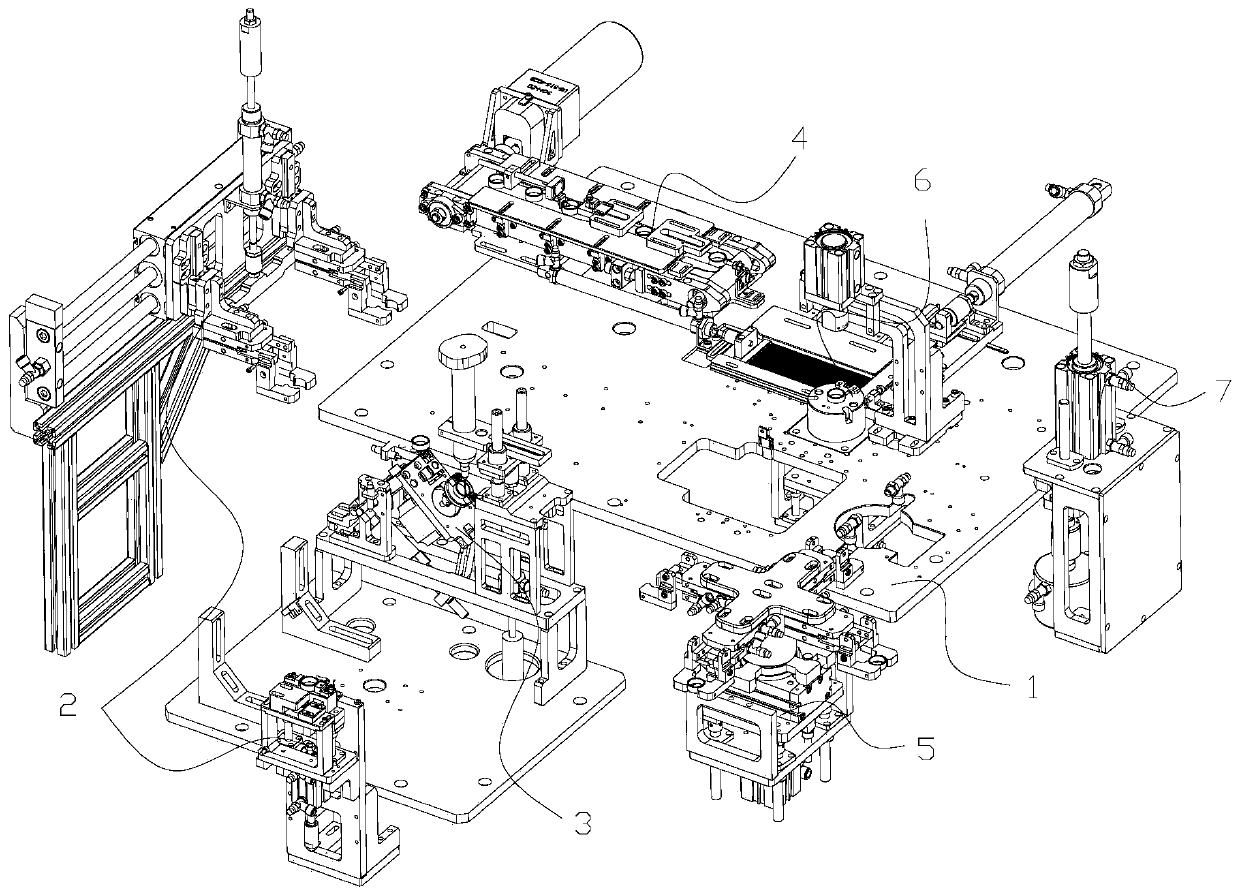

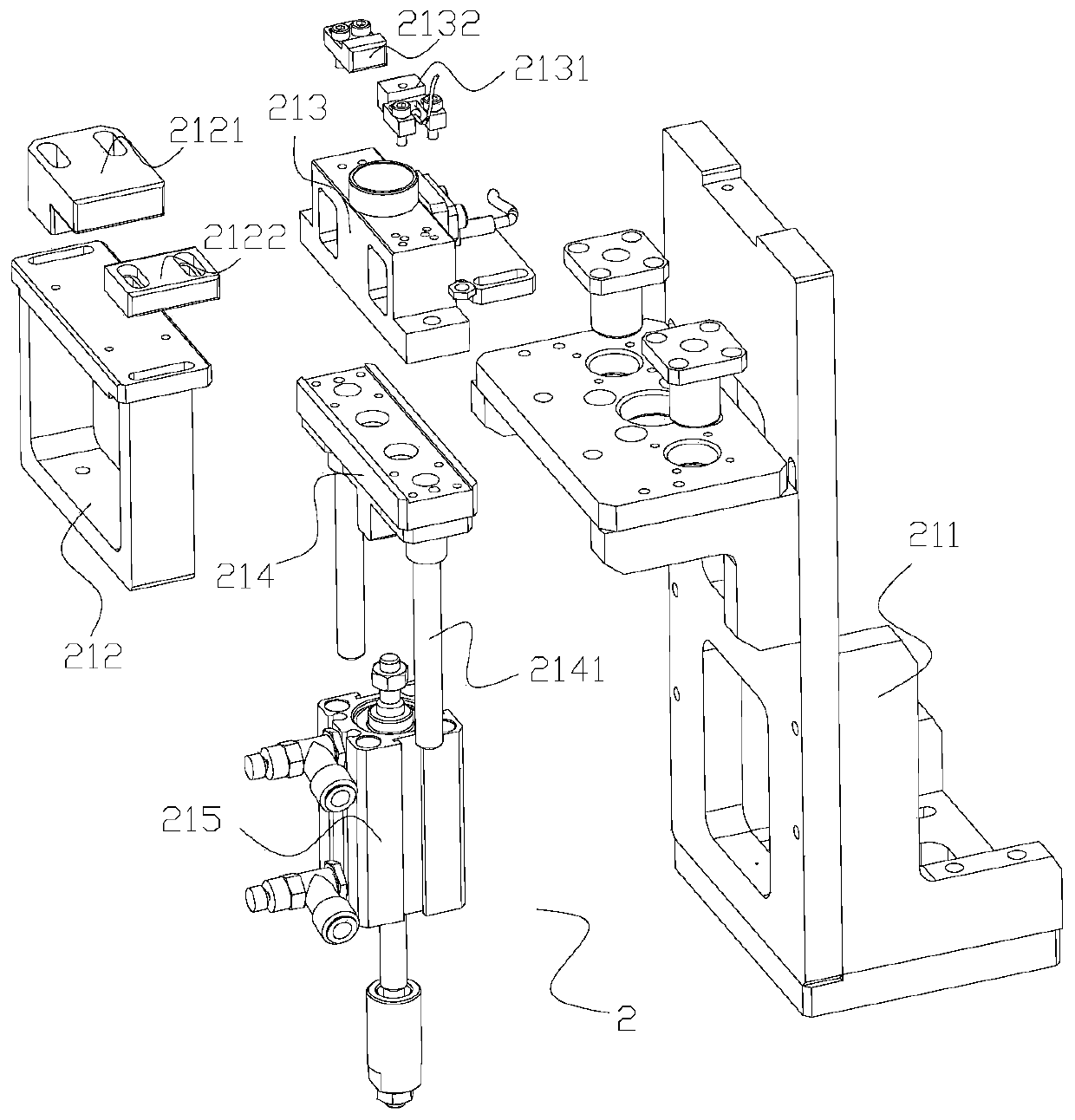

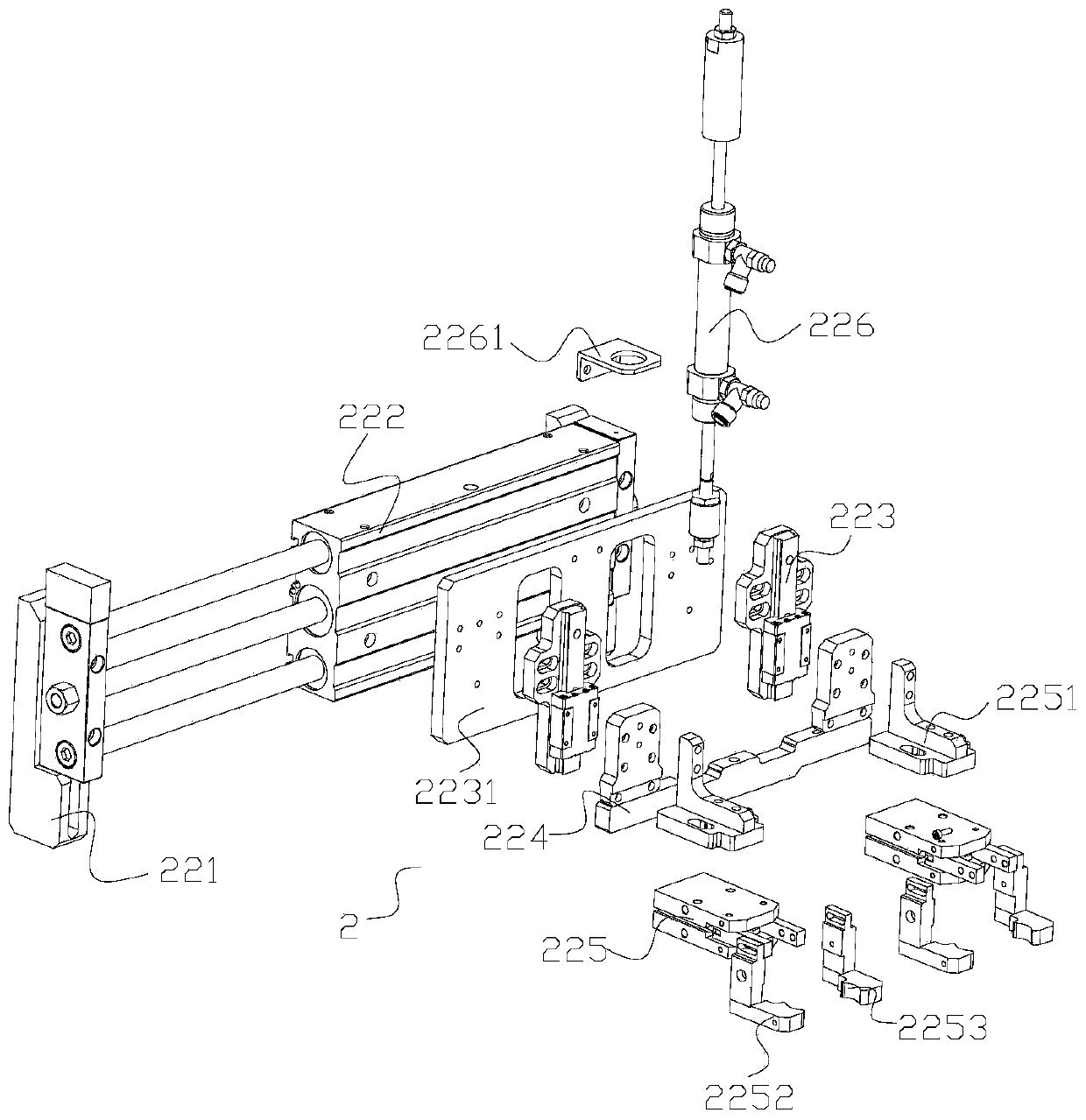

[0034] Such as figure 1As shown, a motor magnetic frame and magnetic strip automatic assembly equipment, the equipment includes a frame 1, a magnetic frame feeding and conveying device 2, a magnetic frame gluing device 3, a magnetic frame conveying device 4, a rotating disk device 5, and a magnetic strip Coil assembly device 6 and magnetizing device 7 . The magnetic frame feeding conveying device 2 is arranged on the frame, and the magnetic frame feeding conveying device 2 comprises a magnetic frame feeding module and a magnetic frame conveying module, the discharge end of the magnetic frame feeding module and the feeding end of the magnetic frame conveying module connected. The magnetic frame feeding module is used to feed the magnetic frame, and the magnetic frame delivery module is used to transport the magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com