Special tool for testing ultra-low temperature valve and detection method of special tool

An ultra-low temperature, valve technology, applied in the direction of detecting the appearance of fluid at the leak point, using liquid/vacuum for liquid tightness measurement, etc., can solve the problems of unable to meet market demand, complicated installation, slow speed, etc., to save raw materials And processing cost, material cost is low, the effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

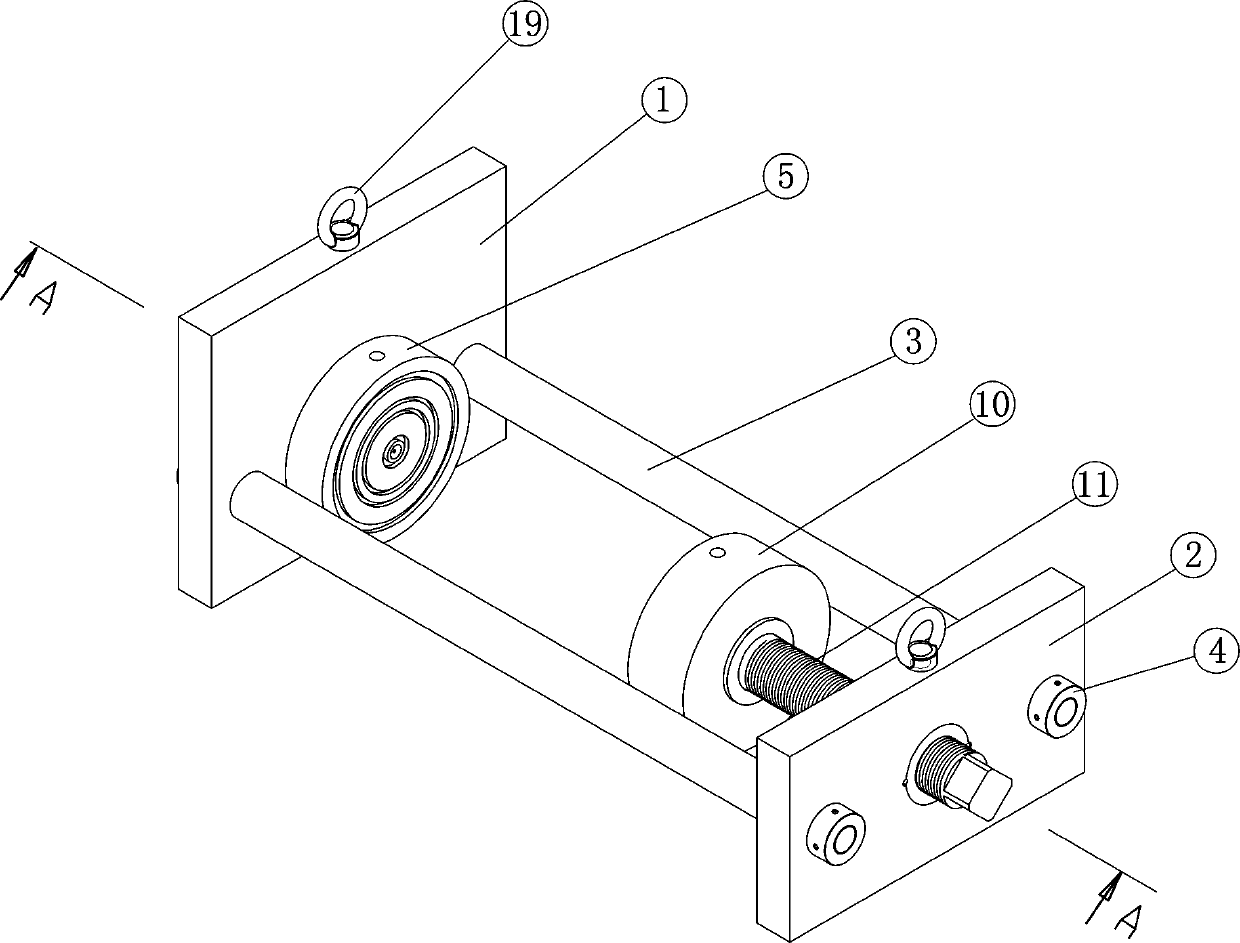

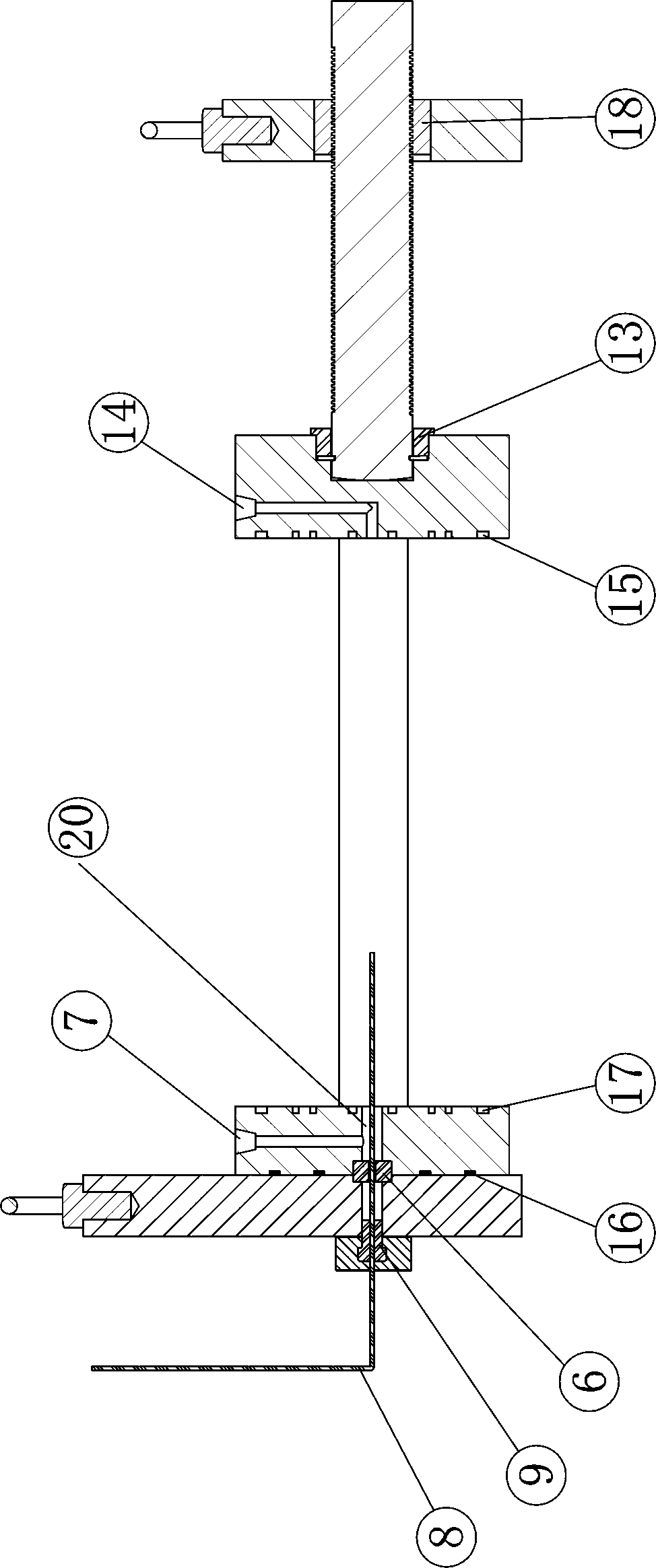

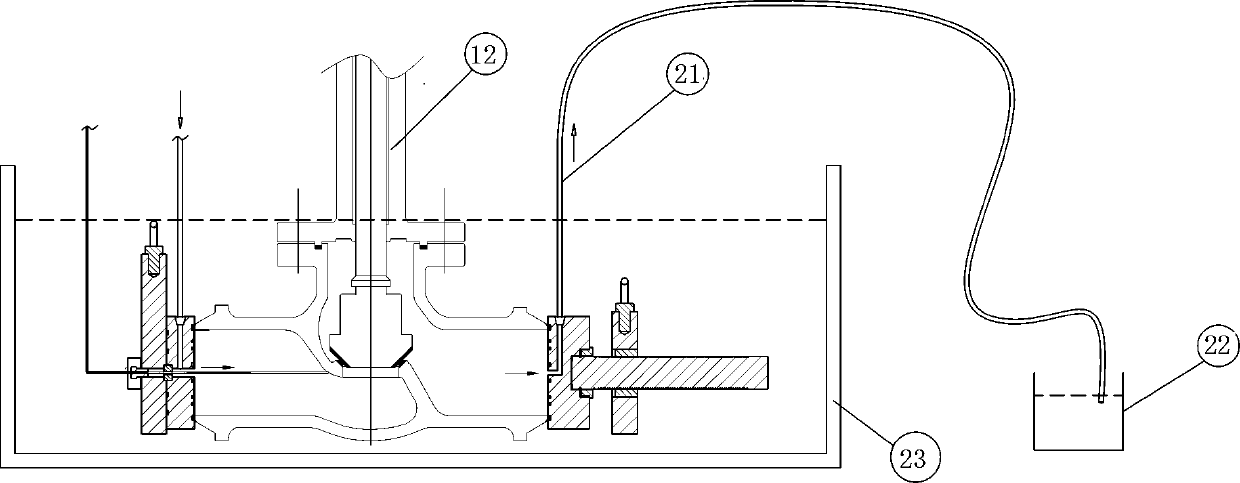

[0026] Such as Figure 1 ~ Figure 2 As shown, a special tooling for ultra-low temperature valve testing, including a main board 1 and a sub-board 2 , the main board 1 and the sub-board 2 are connected and supported by a connecting shaft 3 and locked by a nut 4 . The front sealing disc 5 is threadedly connected with the main board 1 through the connecting buckle 6 and sealed by the sealing ring 16 . An air inlet connection port 7 is provided in the radial direction of the front sealing disc 5, and the low-temperature test medium can enter the valve through the connection port 7. A through hole 20 is formed through the center of the axis of the front sealing disc 5 and the main board 1 , and the through hole 20 communicates with the air inlet connection port 7 . The temperature sensor 8 passes through the through hole 20 through the sealing buckle 9 (the sealing buckle 9 is sealed to prevent gas from leaking through the gap of the temperature sensor) and enters the interior of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com