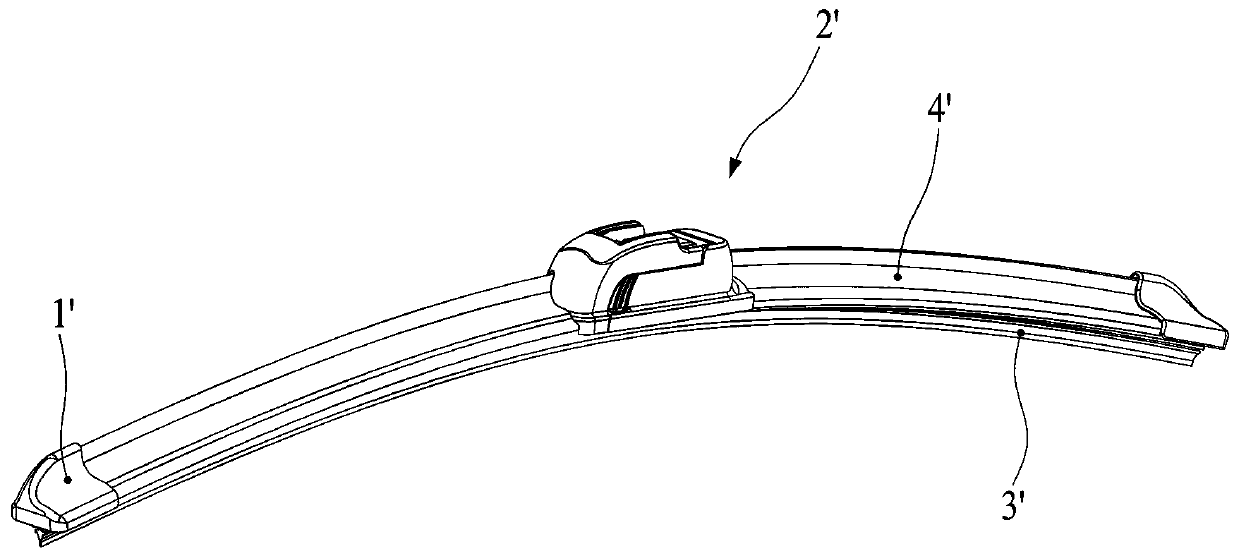

Novel wiper rubber strip anti-releasing structure and wiper thereof

An anti-detachment structure and adhesive strip technology, which is applied in the field of traffic safety, can solve problems such as increased costs, unsightly wiper structure, and stripped strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

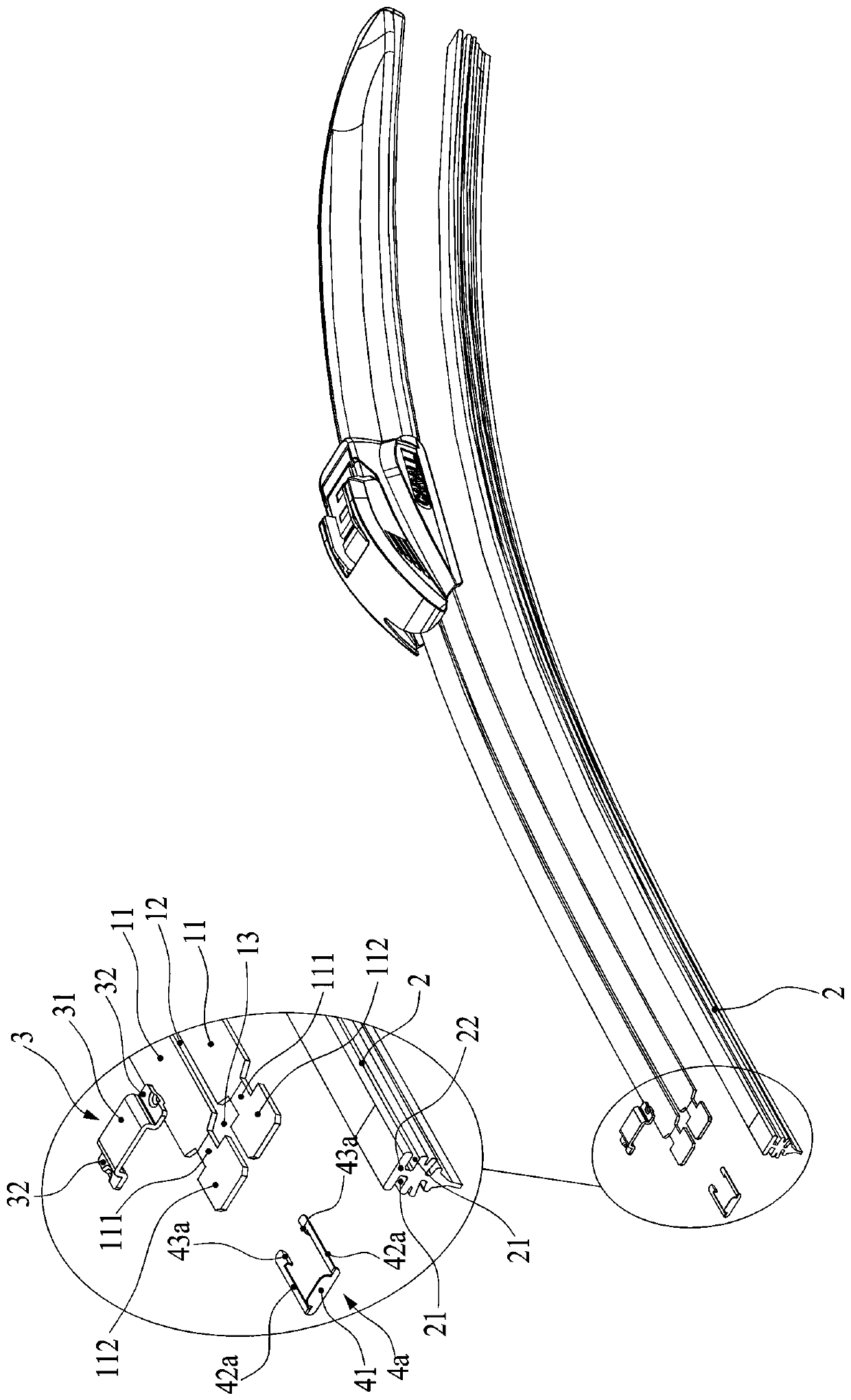

[0047] Such as Figure 2-Figure 5As shown, a new type of wiper rubber strip anti-off structure includes a spring piece 1 and a rubber strip 2. The spring piece 1 is composed of two spring pieces 11 arranged at intervals on the left and right. The two spring pieces 11 are adjacent to each other. The two ends 112 are respectively connected by a connecting piece 3. The middle of the connecting piece 3 is a flat plate 31, and each end is provided with a rest portion 32, which is in the shape of a boss as a whole. The two rest portions 32 are respectively welded to the phases of the two spring segments 11 On the adjacent two ends 112, a through cavity 33 is formed between the connecting piece 3 and the two spring segments 11; a gap 12 is formed in the middle of the two spring segments 11, and the left and right sides of the rubber strip 2 along the length direction Each has a slot 21 for inserting the spring pieces 11, the rubber strip 2 is pushed into the gap 12 between the spring...

Embodiment 2

[0052] The embodiment of the wiper rubber strip anti-off structure is basically the same as the structure of the first embodiment, except that there is a difference in the structure of the rubber strip plug. Therefore, the matching relationship between the rubber strip 2 and the spring piece 11 is that the connecting piece 3 and the The connection mode between the spring segments 11 refers to the description of the first embodiment, and will not be repeated. It should be noted that the two ends of the two spring segments 11 do not need to form the flared portion 13, that is, the flared portion 13 can be eliminated. However, if there is a flaring portion 13, it is convenient for the rubber strip 2 to pass through the gap 12 formed between the spring pieces 11. Such as Figure 6-Figure 8 As shown, the connector 42a of the strip plug 4b is a flat connecting arm 42a, and the two connecting arms 42a are closely attached to the top end surfaces of the two spring segments 11, which a...

Embodiment 3

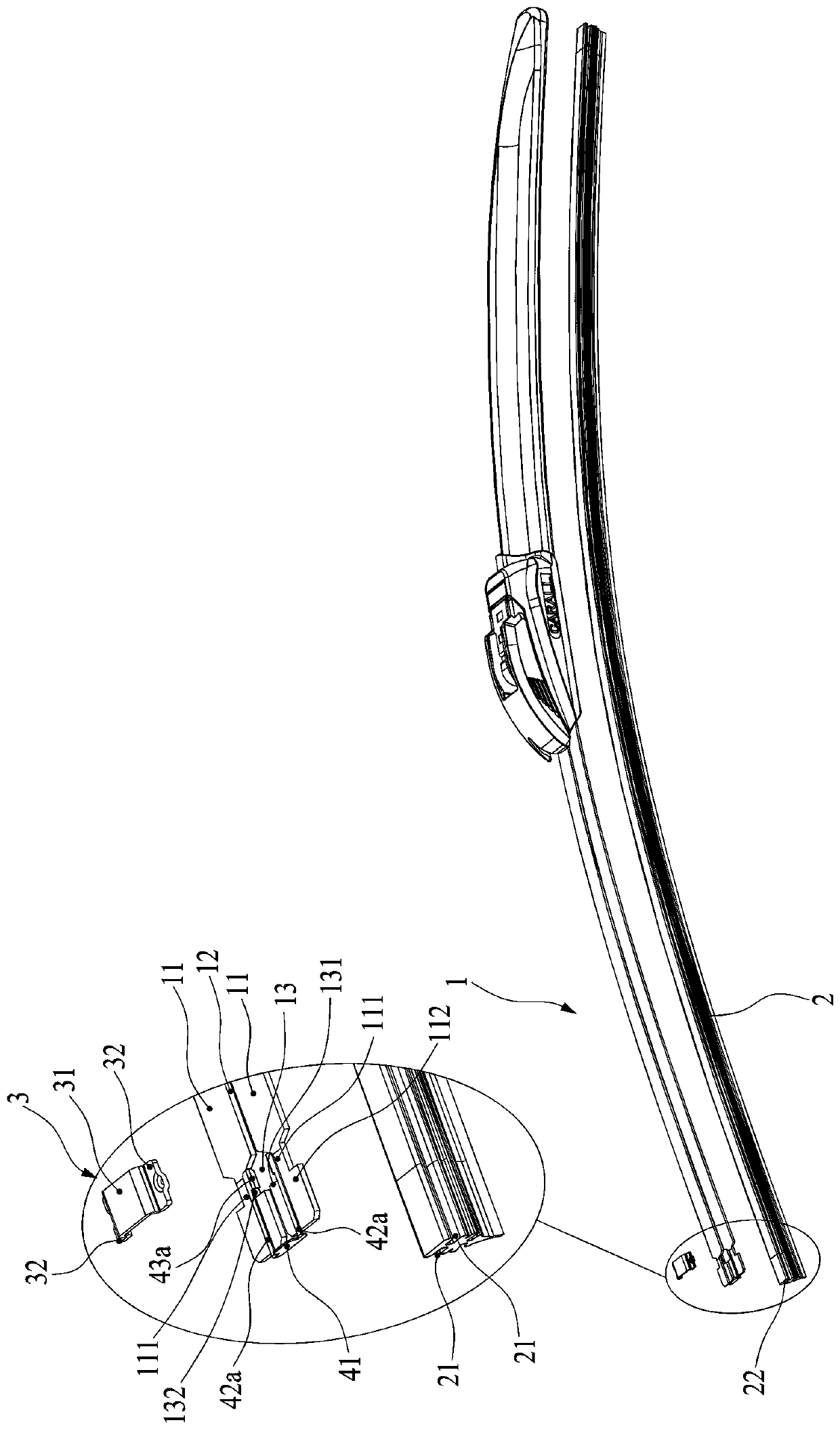

[0056] The embodiment of the wiper rubber strip anti-off structure is basically the same as the structure of the first embodiment, except that there is a difference in the structure of the rubber strip plug. Therefore, the matching relationship between the rubber strip 2 and the spring piece 11 is that the connecting piece 3 and the The connection mode between the spring segments 11 refers to the description of the first embodiment, and will not be repeated. It should be noted that the two ends of the two spring segments 11 do not need to form the flared portion 13, that is, the flared portion 13 can be eliminated. However, if there is a flaring portion 13, it is convenient for the rubber strip 2 to pass through the gap 12 formed between the spring pieces 11. Such as Figure 9-Figure 11 As shown, the connector 42b of the rubber strip plug 4c is a first connector 42b in the shape of a flat plate, the first connector 42b is perpendicular to the spring piece 11, and is located on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com