An automatic sliding door of an oven charging port and an oven

A reclaiming port and oven technology, which is applied in the field of ovens, can solve problems such as poor sealing performance of oven doors, and achieve the effects of good sealing performance, better and uniform adhesion, and improved automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

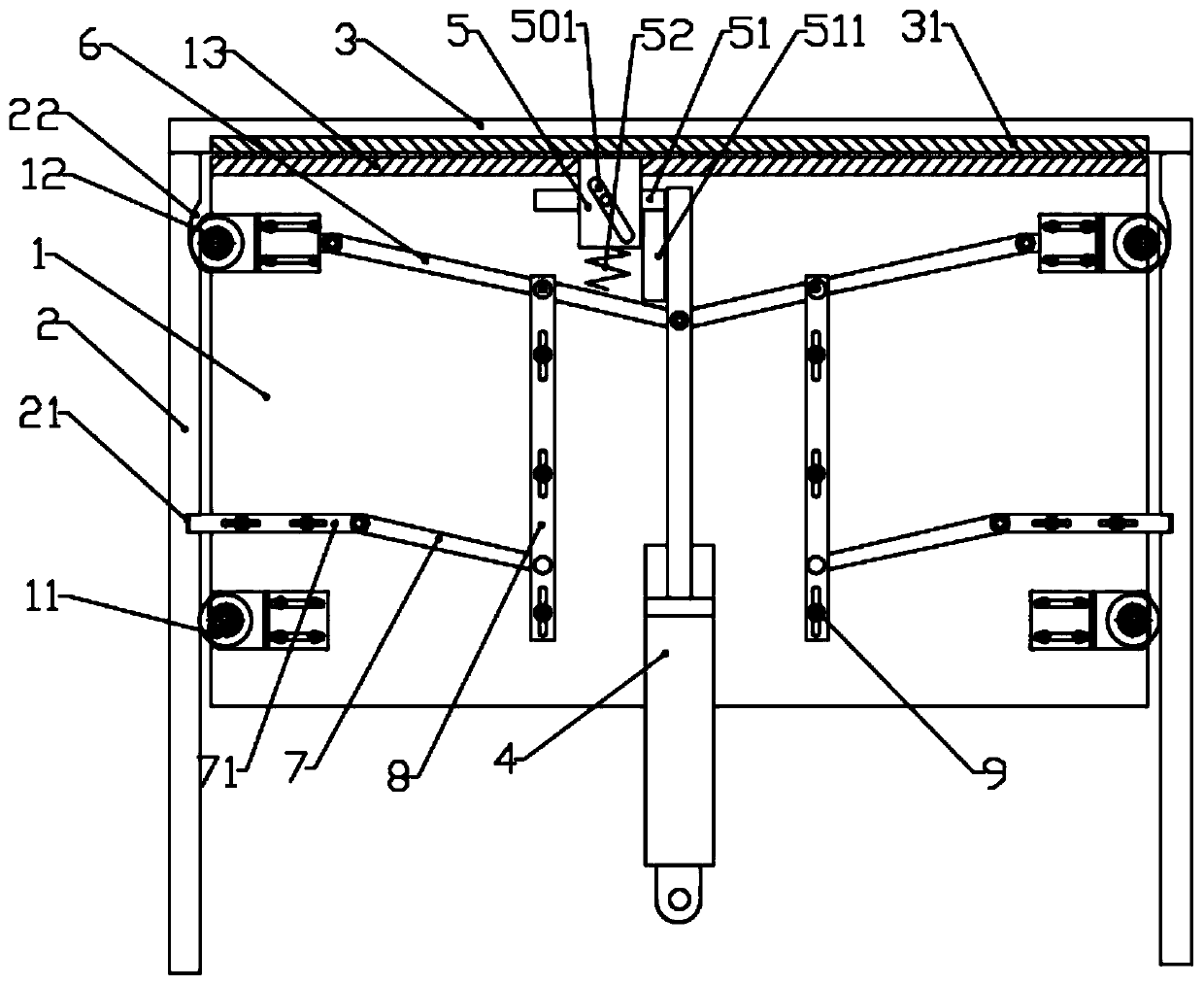

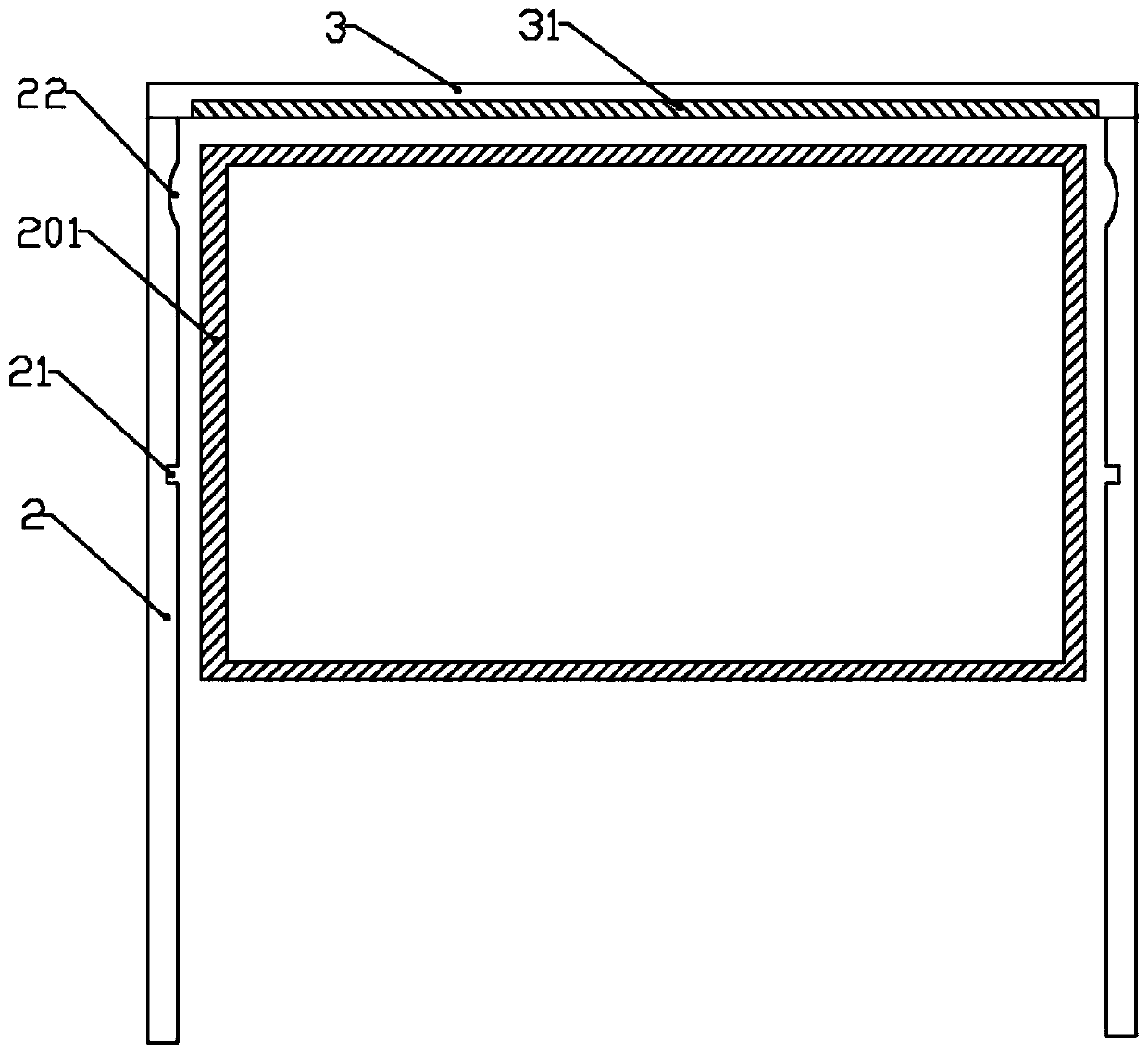

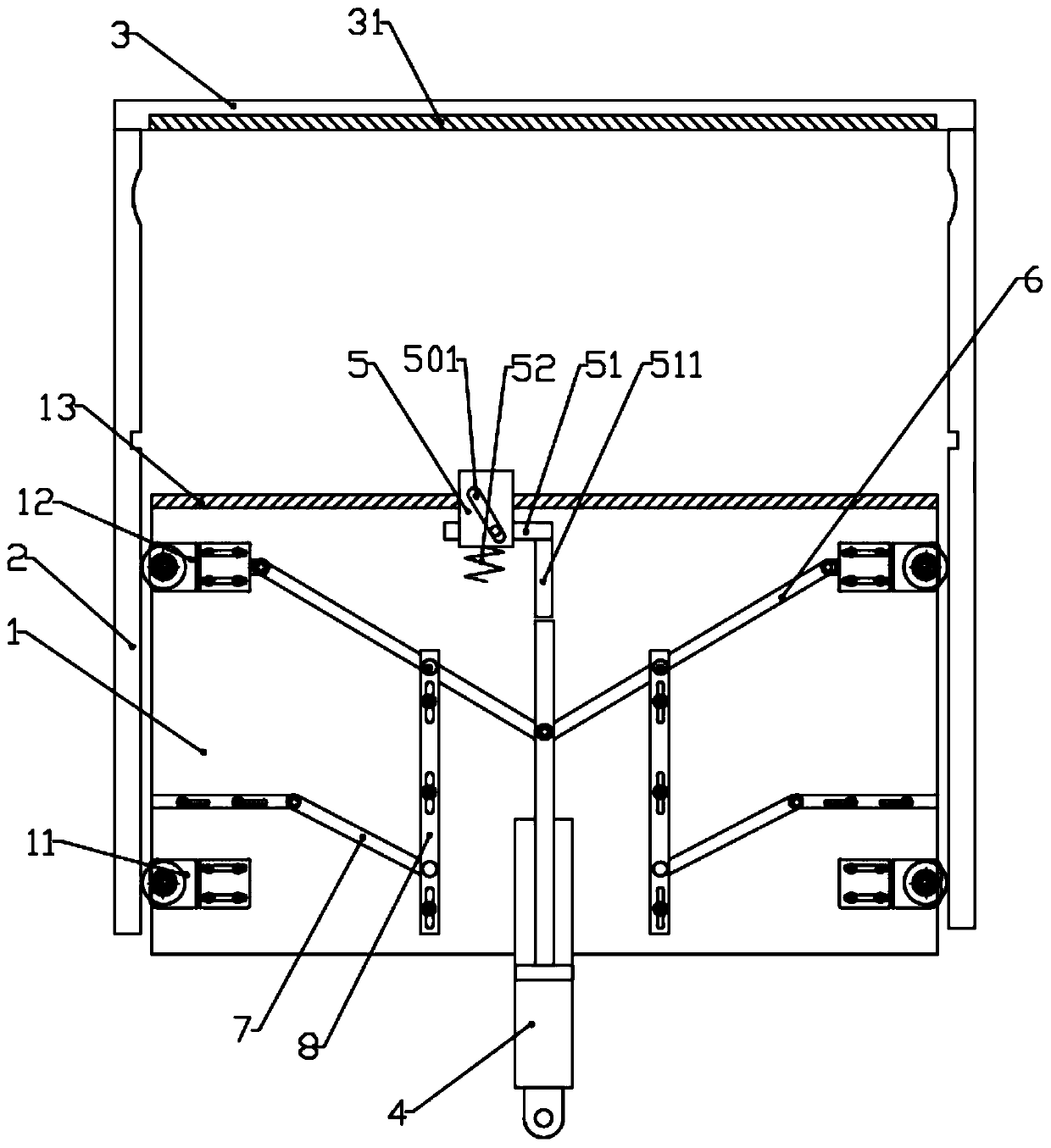

[0025] Such as Figure 1 to Figure 5 As shown: this embodiment discloses an automatic sliding door for the charging port of an oven, including a door body 1, a track and a cylinder 4 for driving the door body 1 to slide along the track, and the track includes two side tracks 2 and an upper track 3 , the inner edge of the track is provided with a sealing strip 201, the side track 2 is provided with a recessed part 22 and a socket 21, and the side of the door body 1 is symmetrically provided with a set of lower guide wheels 11 and a set of upper guide wheels 12, and the upper guide wheels 12 (comprising rollers and roller brackets, wherein the roller brackets are slidably connected to the door bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com