Guide vane of a centrifugal pump

A centrifugal pump and guide vane technology, applied in the direction of pumps, pump components, and components of pumping devices for elastic fluids, etc., can solve problems such as hidden safety hazards, wave peaks and troughs, etc., to reduce backflow and avoid wave peaks and troughs. , the effect of eliminating the hump effect phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

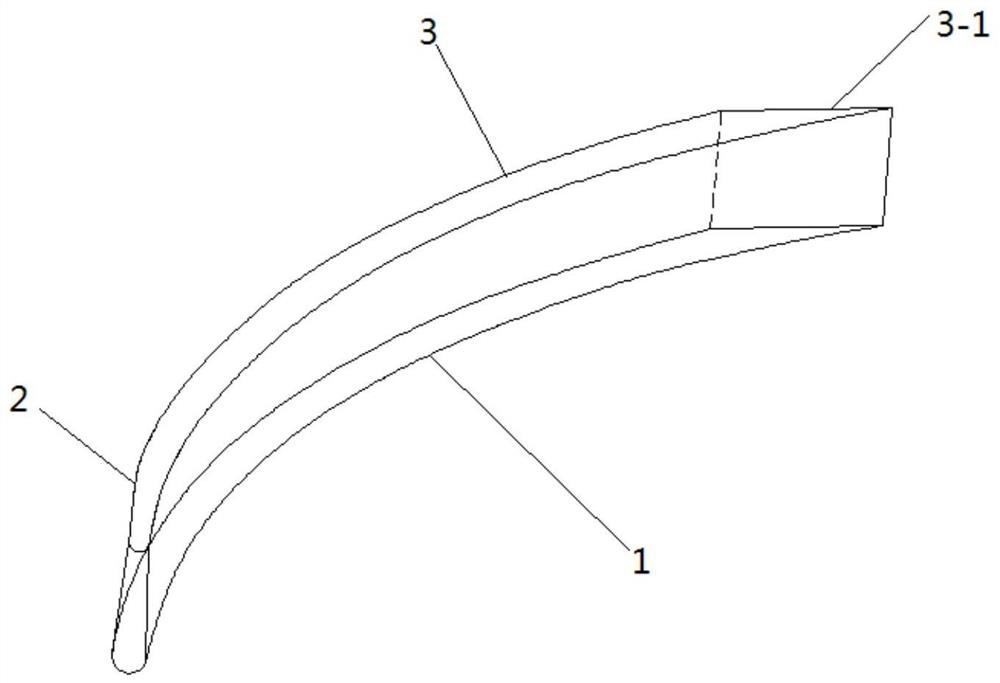

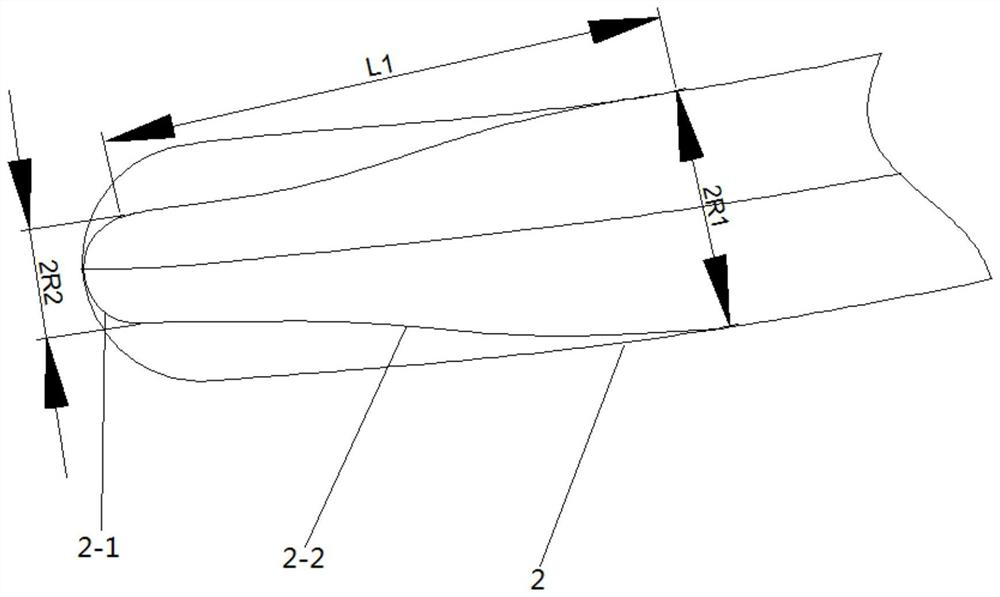

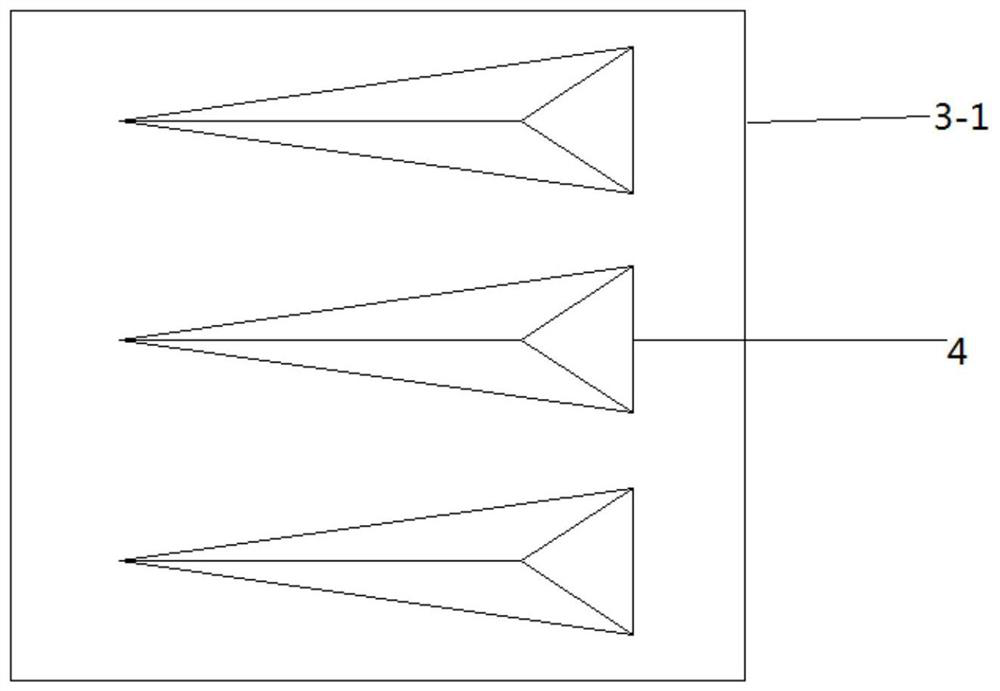

[0027] A guide vane of a centrifugal pump, such as figure 1 As shown, the guide vane body 1 is included, and the guide vane body is fixed by the upper cover plate and the lower cover plate. The guide vane body 1 includes a leading edge segment 2 and a trailing edge segment 3 connected in sequence, and the thickness of the leading edge segment 2 is along the upper cover plate. The direction of the downward cover plate increases successively, such as figure 2 As shown, the width of the upper surface (close to the upper cover) of the leading edge section 2 is smaller than the width of the lower surface (close to the lower cover), the width of the head of the upper surface of the leading edge section 2 is smaller than the width of the tail, and the front The two sides of the upper surface of the edge section 2 are curved lines; the thickness of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com