Belt conveying mechanism with suction force

A belt conveying and suction technology, applied in the direction of conveyor objects, transportation and packaging, rollers, etc., can solve the problems of falling, material waste, increasing people's workload, etc., and achieve the effect of reducing friction and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

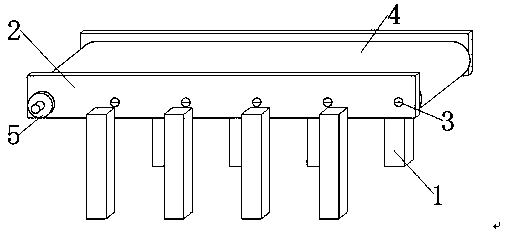

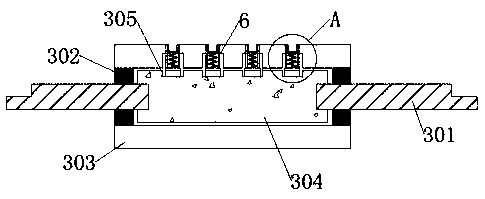

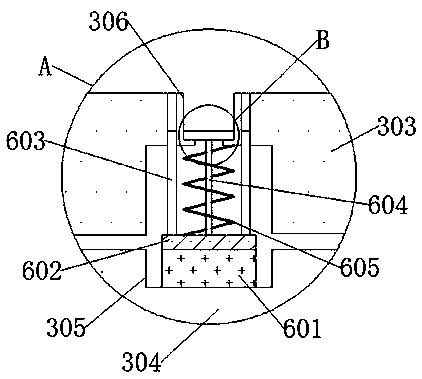

[0028] see Figures 1 to 7 Among them, in the embodiment of the present invention, a belt conveying mechanism with suction force includes a tripod 1, a roller 3, a driving cylinder 5, a belt 4 and a skeleton 2, the top of the tripod 1 is welded with a skeleton 2, and the tripod 1 They are respectively arranged at the front and rear ends of the frame 2. The internal welding of the frame 2 is provided with five rollers 3. The surface of the rollers 3 is closely attached to the belt 4, and the belt 4 wraps the five rollers 3. The front ends of the rollers 3 are nested and welded. There is a driving cylinder 5; the drum 3 includes a fixed rod 301, a bearing 302, a rotating cylinder 303, a central column 304, a groove 305, a suction hole 306 and a gap 307, and one end of the fixed rod 301 is welded with a bearing 302, and the fixed rod 301 There are two bearings 302 respectively welded on both sides of the inner wall of the rotating cylinder 303, a central column 304 is provided be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com