Full-automatic film tearing and foam attaching dual-purpose machine

A foam sticking, fully automatic technology, applied in the direction of winding strips, packaging, thin material processing, etc., can solve the problems of low degree of automation, single function, low efficiency, etc., and achieve the effect of diverse functions and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

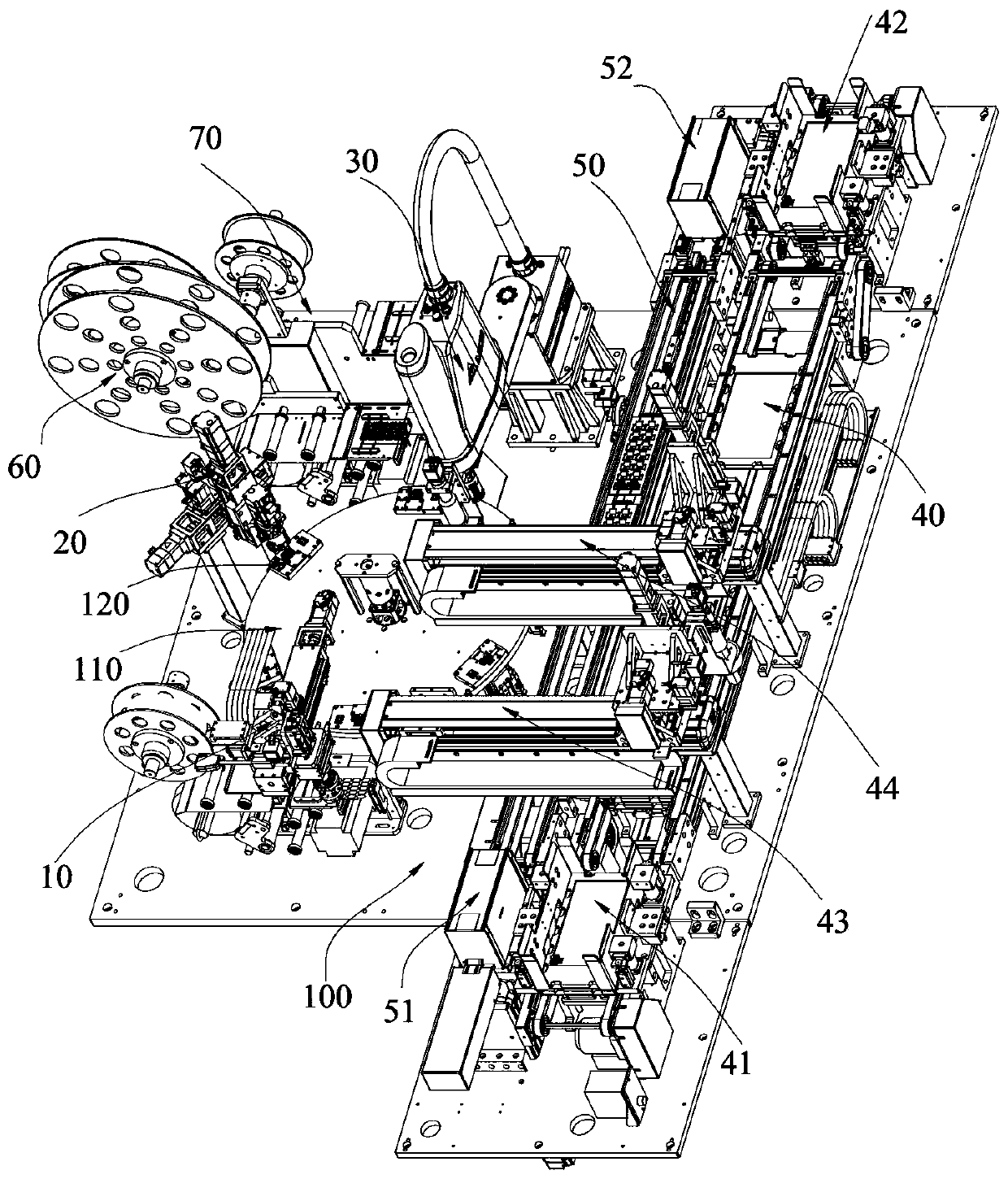

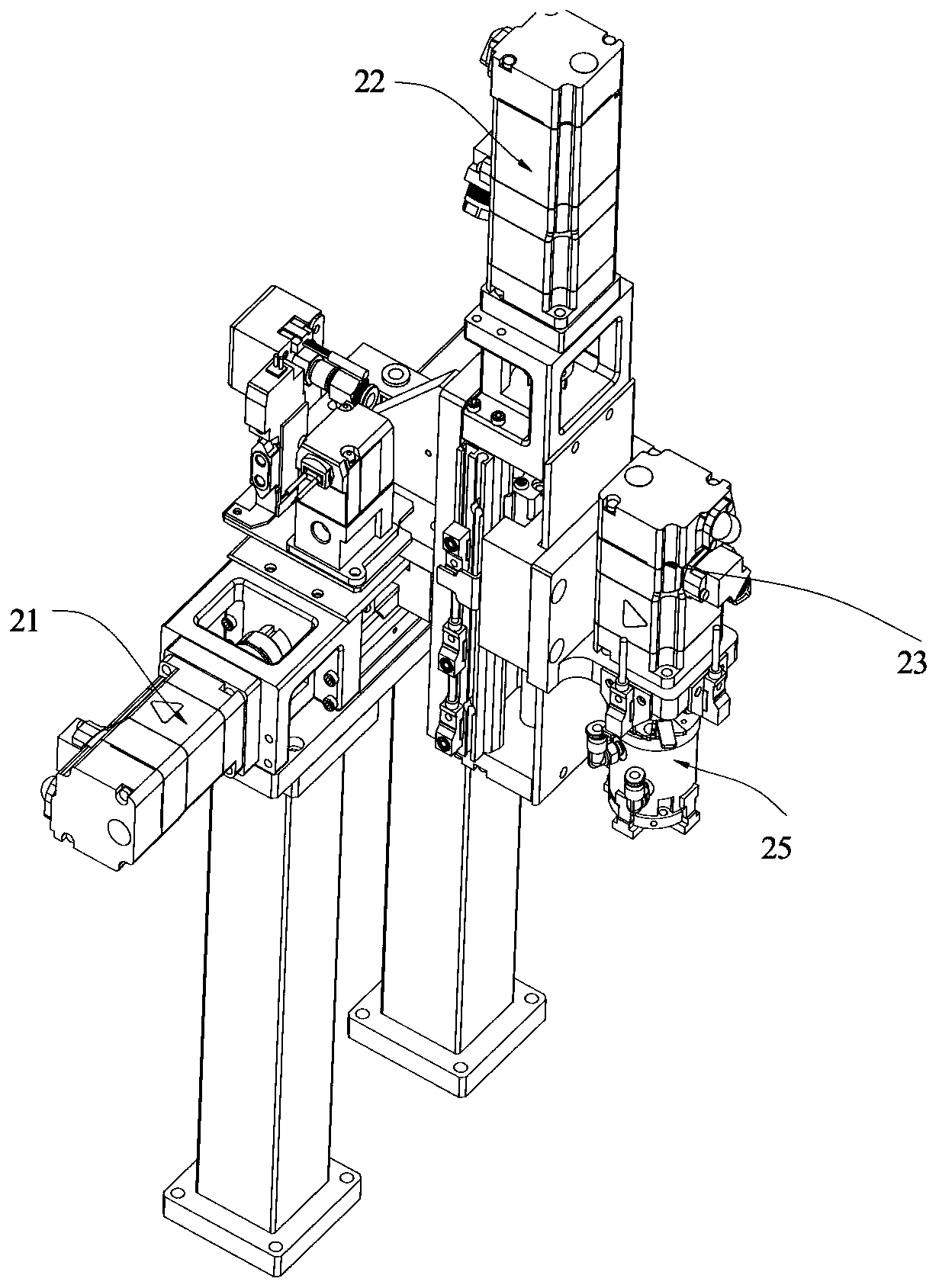

[0034] Such as Figure 1-9A fully automatic film tearing and foam sticking dual-purpose machine shown includes a body 100, a PET film attaching mechanism 10, a foam tearing mechanism 20 and a foam attaching mechanism 30, a PET film attaching mechanism 10, a foam Both the cotton tearing mechanism 20 and the foam sticking mechanism 30 are installed on the body 100 . A working platform 110 is provided on the machine body 100 , and a plurality of workpiece loading fixtures 120 are provided on the working platform 110 , and a workpiece slot 121 and a foam slot 122 are provided on the workpiece loading jig 120 . The specific PET film attachment mechanism 10 is used to attach the PET film to the workpiece surface in the workpiece groove 121; the foam tearing mechanism 20 is used to tear the foam on the workpiece in the workpiece groove 121 and place the foam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com