Self-casting mechanism with upper demolding mechanism and lower demolding mechanism

A demoulding mechanism and mold technology, which is applied in the direction of manufacturing tools, casting equipment, and equipment for transporting molds, etc., can solve problems such as troubles, and achieve the effect of convenient ejection and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

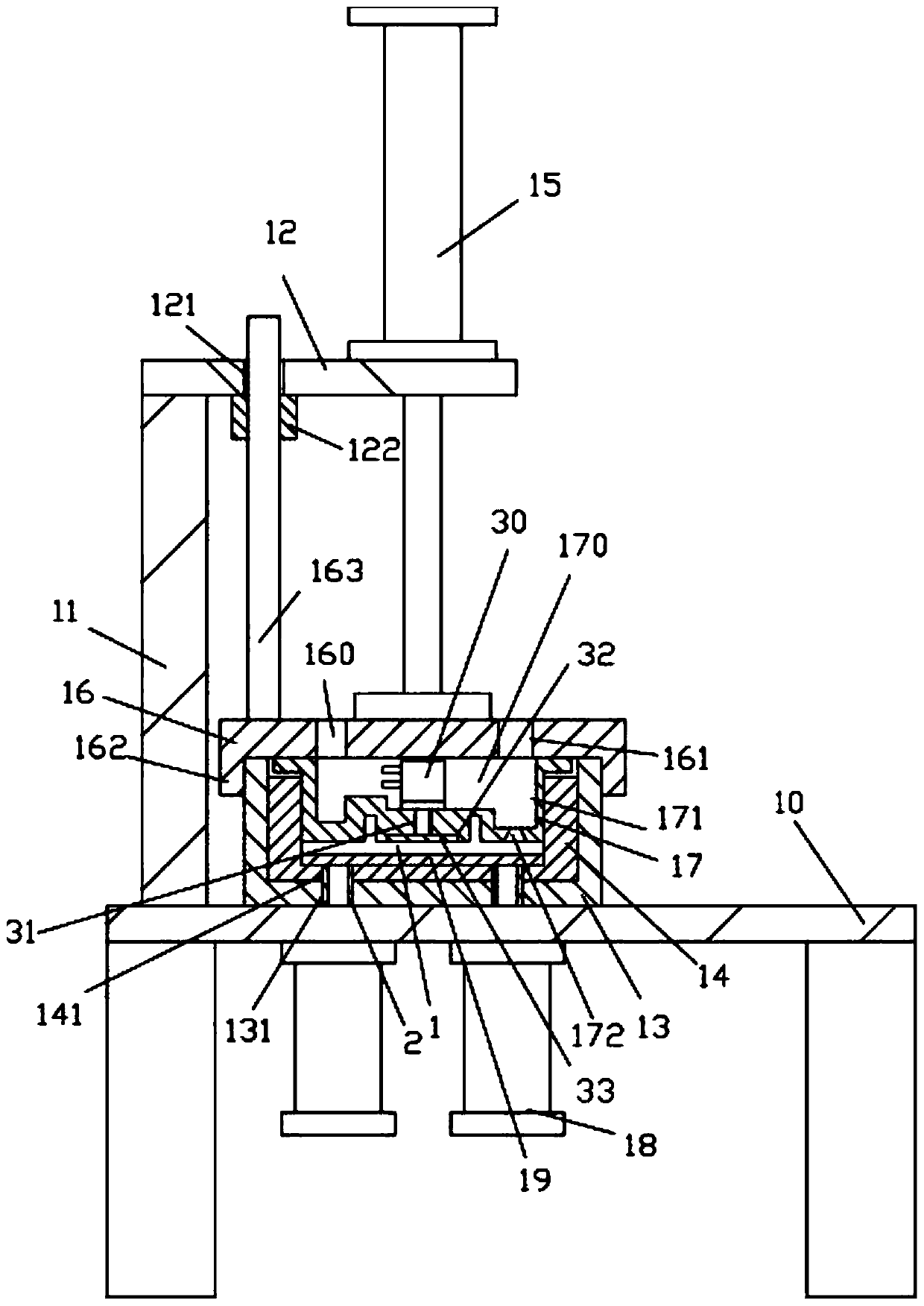

[0016] Examples, see e.g. figure 1 As shown, a self-casting mechanism with an upper and lower demoulding mechanism includes a frame 10, a vertical support plate 11 is fixed on the left top surface of the top plate of the frame 10, and a vertical support plate 11 is fixed on the top surface of the vertical support plate 11. Last fixed plate 12, the top surface of the top plate of the frame 10 directly below the upper fixed plate 12 is fixed with a lower fixed shell 13, the inside of the lower fixed shell 13 is equipped with a lower casting mold 14, the side wall of the lower casting mold 14 Fixed on the inner side wall of the lower fixed housing 13, the bottom surface of the lower casting mold 14 is pressed against the top surface of the bottom plate of the lower fixed housing 13, and the upper pressing oil cylinder 15 is fixed on the upper surface of the upper fixing plate 12, and the upper pressing The push rod of the oil cylinder 15 passes through the bottom surface of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com