5A molecular sieve adsorbent as well as preparation method and application thereof

A molecular sieve and adsorbent technology, which is applied in the field of 5A molecular sieve adsorbent and its preparation, can solve the problem of insufficient heavy wax adsorption, and achieve the effect of high content of 5A molecular sieve, large adsorption capacity and high adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

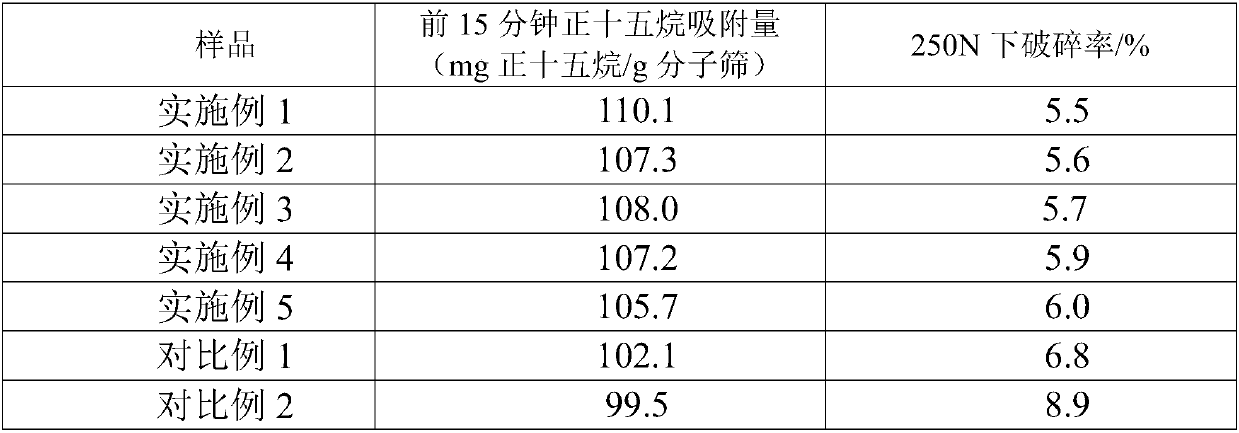

Examples

Embodiment 1

[0097] (1) Get 400kg of commercially available 4A molecular sieve former powder (moisture content is 21% by weight, average grain diameter is 0.7μm, methanol adsorption capacity is 181mg / g) and kaolin 20kg (water content is 22% by weight) ), 10kg of safflower powder pore-forming agent was put into a twin-screw mixer and mixed for 3 hours, and 50kg of the mixed material was taken out, and put into a rolling ball pot (sugar-coated pot) with a diameter of 1.2m to carry out rolling ball molding to make small The operating conditions in the ball (rolling ball pot include: the speed control is 30 rpm, the water addition rate is based on the water content of the material increasing by 3-5% by weight per hour, and when the final moisture content of the material reaches 45-50% by weight, stop adding water , then keep the rotating speed of the rolling ball pot at 30-40 rpm, and continue to rotate for 3-5 hours), when the ball grows to a diameter of 0.3-1.0mm, polish it for 1-2 hours, and...

Embodiment 2

[0102]Prepare 5A molecular sieve adsorbent beads according to the method of Example 1. The difference is that the ambient humidity of stage (1) is 30% RH, and the ambient humidity of stage (2) is 80% RH, so that the water content of the matrix beads reaches 20% % by weight; all the other conditions are the same to obtain the 5A molecular sieve pellet adsorbent (the water content of the adsorbent is 2.8% by weight, in terms of dry weight of the adsorbent, the content of the 5A molecular sieve is 97.0% by weight, and the diameter is 0.3-0.9mm. The average particle size of the agent is 0.7μm, n(SiO 2 ) / n(Al 2 o 3 ) molar ratio is 1.99, specific surface area is 517m 2 / g, the range of molecular sieve crystal grains is 0.44-0.68, and the mass percentage is 53%, and related properties such as the adsorption capacity of n-pentadecane are shown in Table 1).

Embodiment 3

[0104] Prepare 5A molecular sieve adsorbent beads according to the method of Example 1, the difference is,

[0105] Send the pre-wetted matrix pellets into the synthesis kettle to contact with the sodium hydroxide aqueous solution to carry out crystal transformation treatment, wherein the volume ratio of the sodium hydroxide aqueous solution to the pre-wetted matrix pellets is 2.5, and the sodium hydroxide aqueous solution The concentration is 0.12mol / L, wherein, the temperature is 96°C, and the time is 3 hours. All the other conditions are the same, obtain the 5A molecular sieve pellet adsorbent (the water content of the adsorbent is 2.9% by weight, in terms of the dry weight of the adsorbent, the content of the 5A molecular sieve is 97.0% by weight, the diameter is 0.3-0.9mm, and the average particle size of the adsorbent is The diameter is 0.8μm, n(SiO 2 ) / n(Al 2 o 3 ) The molar ratio is 2.00, and the specific surface area is 515m 2 / g, the range of molecular sieve crys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com