Efficient displacement recycling ventilation cluster system

A cluster system and recirculation technology, applied in ventilation systems, space heating and ventilation, space heating and ventilation details, etc., can solve the problems of air duct system layout restrictions, heating energy waste, consumption and other problems, reaching any group. The group is convenient and flexible, convenient for maintenance, and the effect of low one-time investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

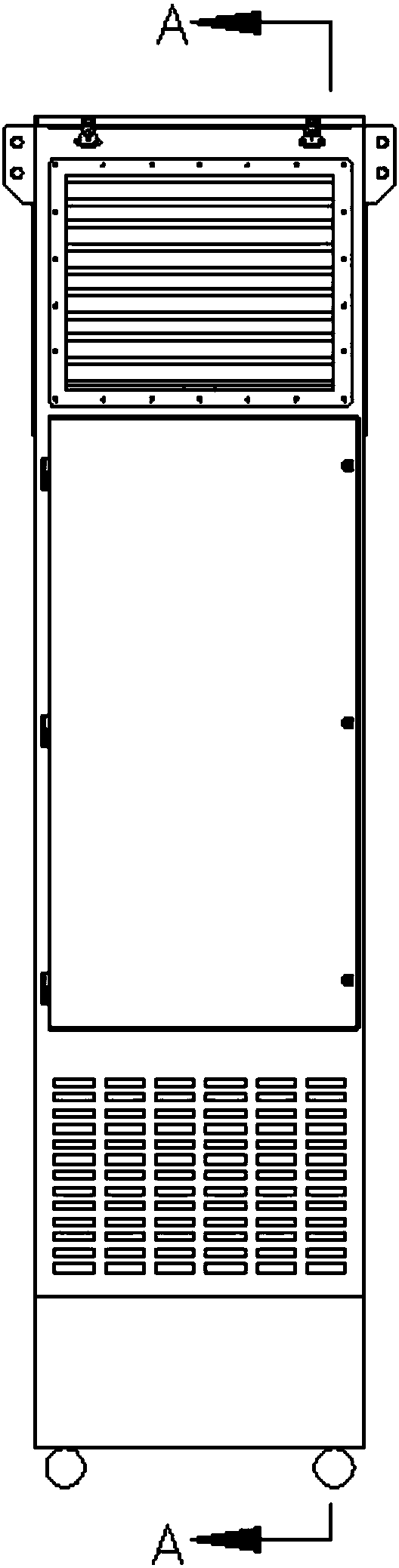

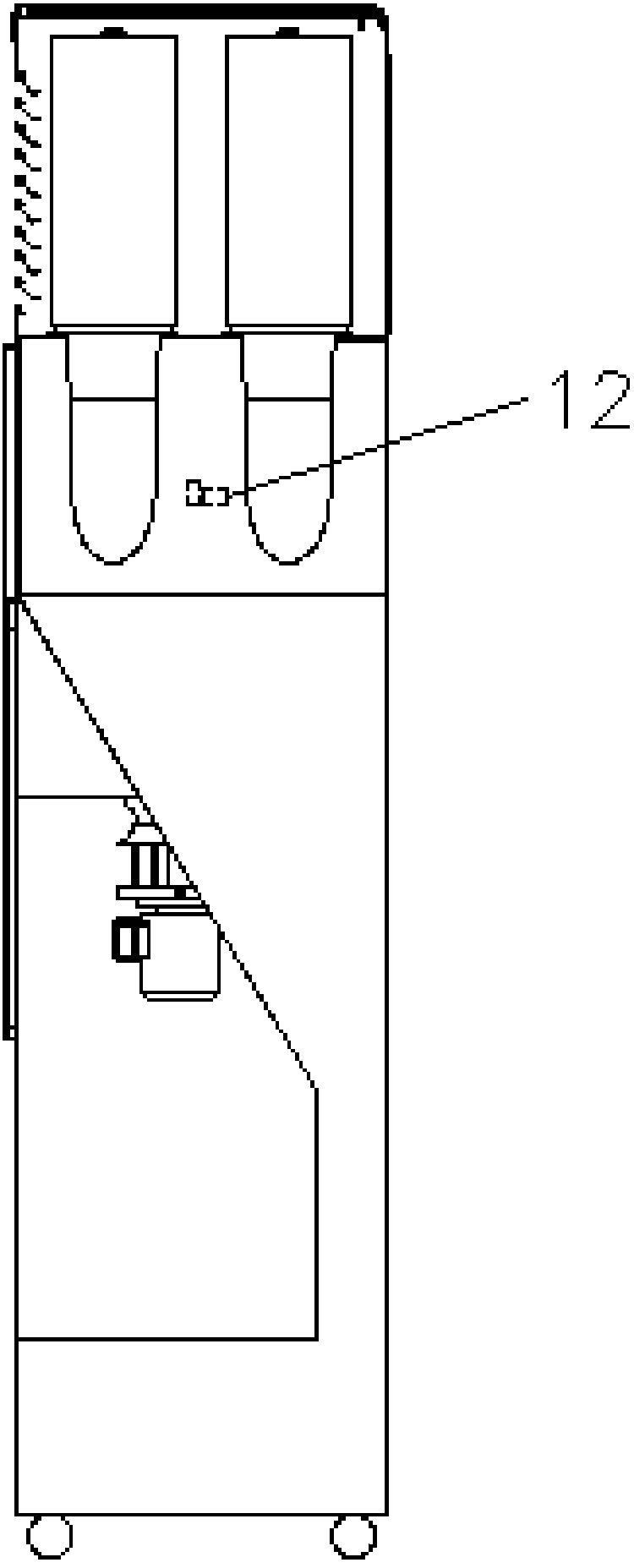

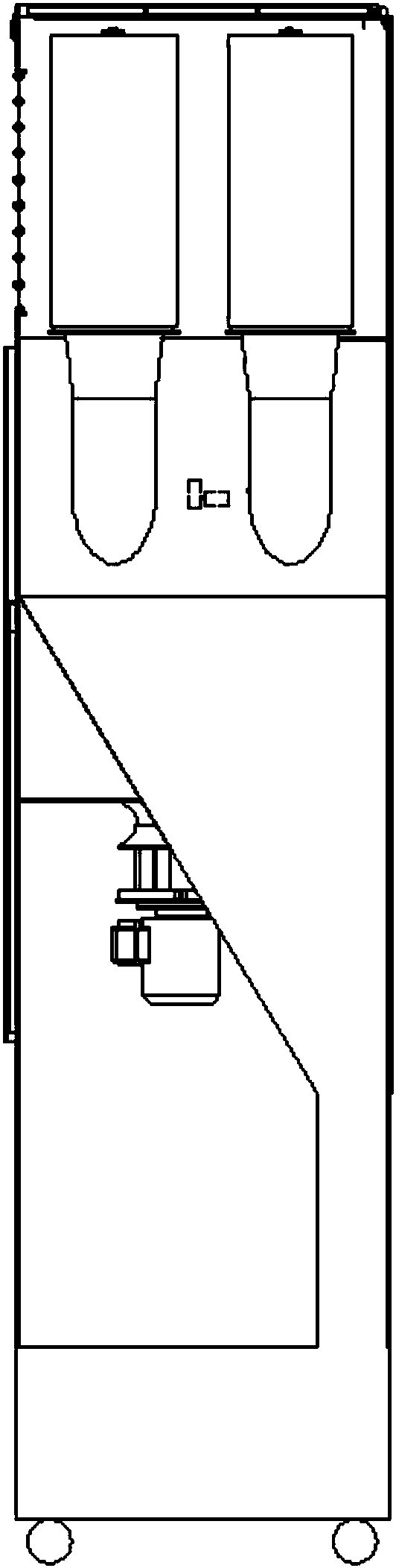

[0045] Below in conjunction with specific implementation methods and attached Figure 1-18 The present invention is described further:

[0046] A high-efficiency displacement recirculation ventilation cluster system installs several displacement filter ventilation units 16 connected in series or in parallel or mutually independent in the factory building. The displacement filter ventilation unit 16 adopts the ventilation and dust removal method of upper air intake and lower air outlet. The air outlet 9 of the displacement filter ventilation unit 16 is 0.5 meters above the ground. It also includes a fresh air exchange device 15 installed on the top of the factory building. The height of the air inlet 2 of the replacement filter ventilation unit 16 from the ground is 5 meters. The replacement filter ventilation unit 16 includes a housing 1, the housing 1 includes a pollutant gas channel, a filter cartridge 3 and a clean gas channel, the upper part of the housing 1 is provided ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com