Grab structure of dishwasher

A grasping structure, dishwasher technology, applied in the direction of washing machine/rinsing machine parts of tableware, etc., can solve the problems of unable to grasp the shape and unevenness of the bowl, and the grasping is not firm, so as to improve the grasping ability, The effect of increasing elasticity and ensuring firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

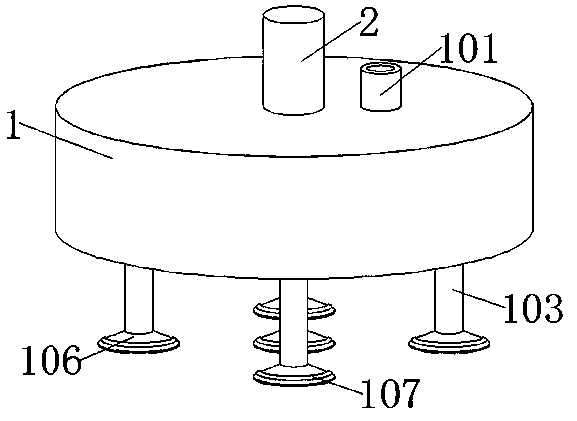

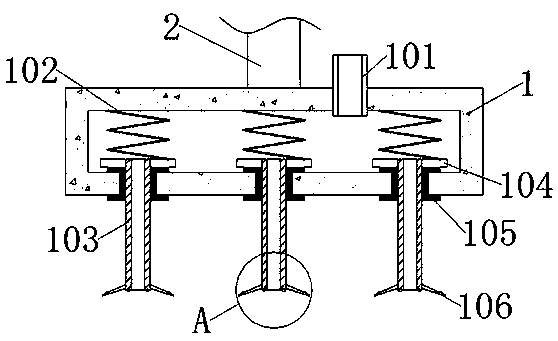

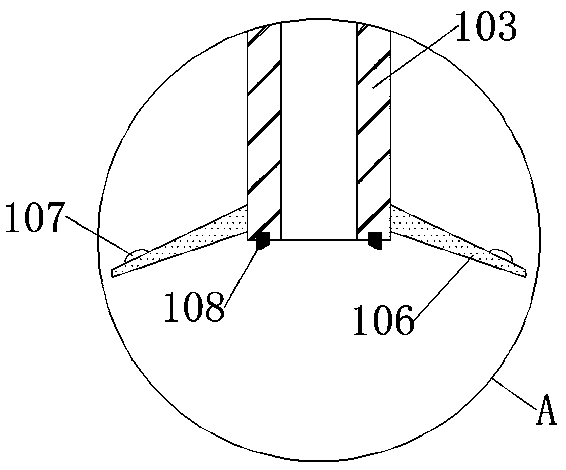

[0014] see Figures 1 to 3 Among them, in the embodiment of the present invention, a grasping structure of a dishwasher includes a hollow disc 1 and a connecting rod 2, the top of the hollow disc 1 is welded with a connecting rod 2, and the hollow disc 1 includes a connecting pipe 101, a spring 102, Hollow rod 103, carrier plate 104, rubber washer 105, suction cup 106, rubber ring 107 and rubber ring 108, the top of the hollow disc 1 is embedded with a connecting pipe 101, and the inner wall of the hollow disc 1 is welded with five springs 102. Five hollow rods 103 are movably embedded in the bottom of 1, the top of the hollow rods 103 is welded with a carrier plate 104, and the bottom of the spring 102 is respectively welded with the carrier plate 104, and the bottom of the hollow disc 1 is embedded with five rubber washers 105 , the bottoms of the hollow rods 103 are embedded and bonded with suction cups 106 , the upper surfaces of the suction cups 106 are bonded with rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com