Automatic potato peeling processing device

A processing device, potato technology, applied in the peeling of vegetables or fruits, food science, application, etc., can solve the problem of small application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

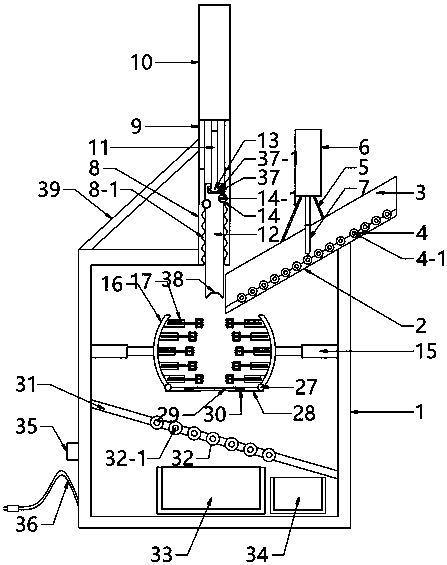

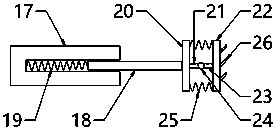

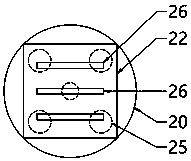

[0017] Attached below Figure 1~4 The present invention is described in detail below.

[0018] Such as Figure 1~4As shown, the present invention includes an outer box body 1, a rotating rod 12 and a blade holder 22, the top surface of the outer box body 1 is open on the right, and the top of the right side wall is fixedly connected with a chute 2, and the chute 2 faces downward to the left. The two fixed baffles 3 are fixedly connected to the front and rear sides of the chute 2, and a number of first conveying roller shafts 4-1 are fixedly connected between the two fixed baffles 3, and the first conveying roller shaft 4-1 is externally connected with The first conveying roller 4 is so that the potatoes roll into the outer box body 1 along the chute 2, the upper end of the middle part of the baffle plate is fixedly connected with the mounting frame 5, and the top end of the mounting frame 5 is fixedly connected with the first reciprocating motor 6. The frame 5 can not only b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com