Preparation method and production mould for light-transmitting concrete

A light-transmitting concrete and manufacturing method technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of easy bending of optical fibers, difficult positioning of optical fibers, and floating, etc., to achieve the effects of improving production efficiency, ensuring regularity, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

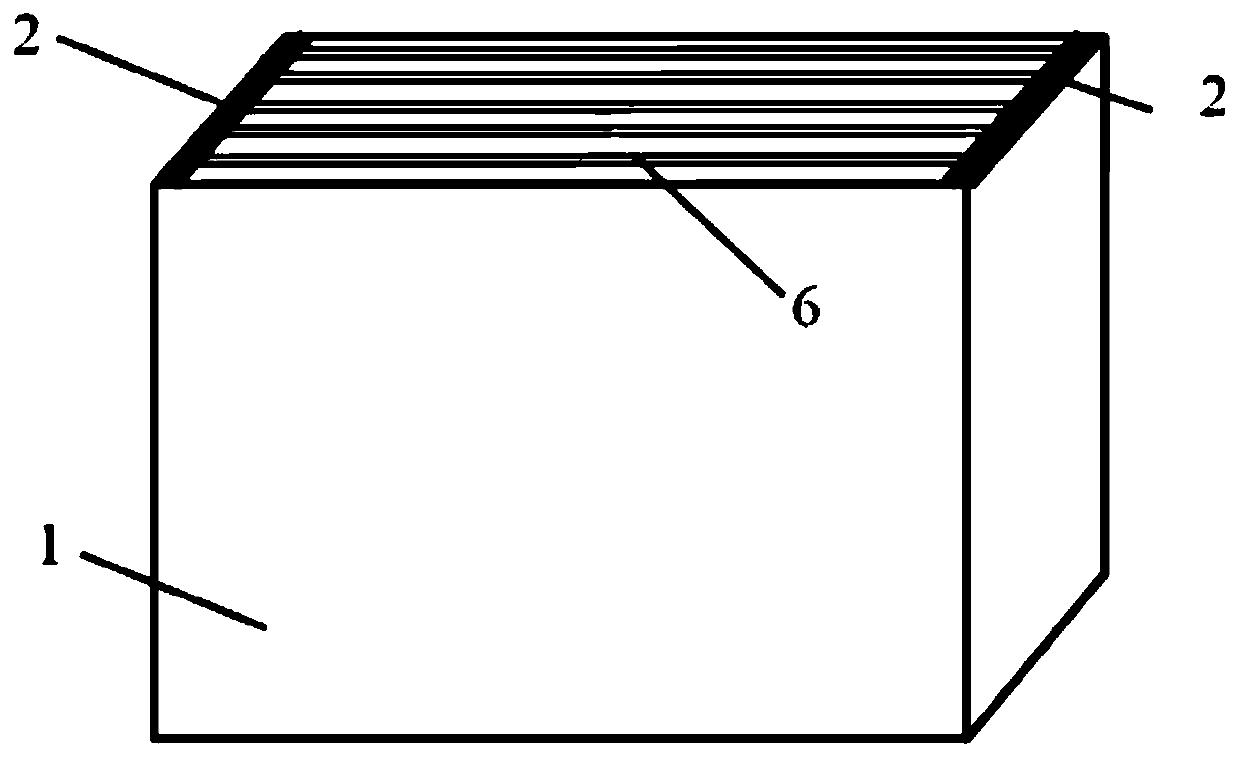

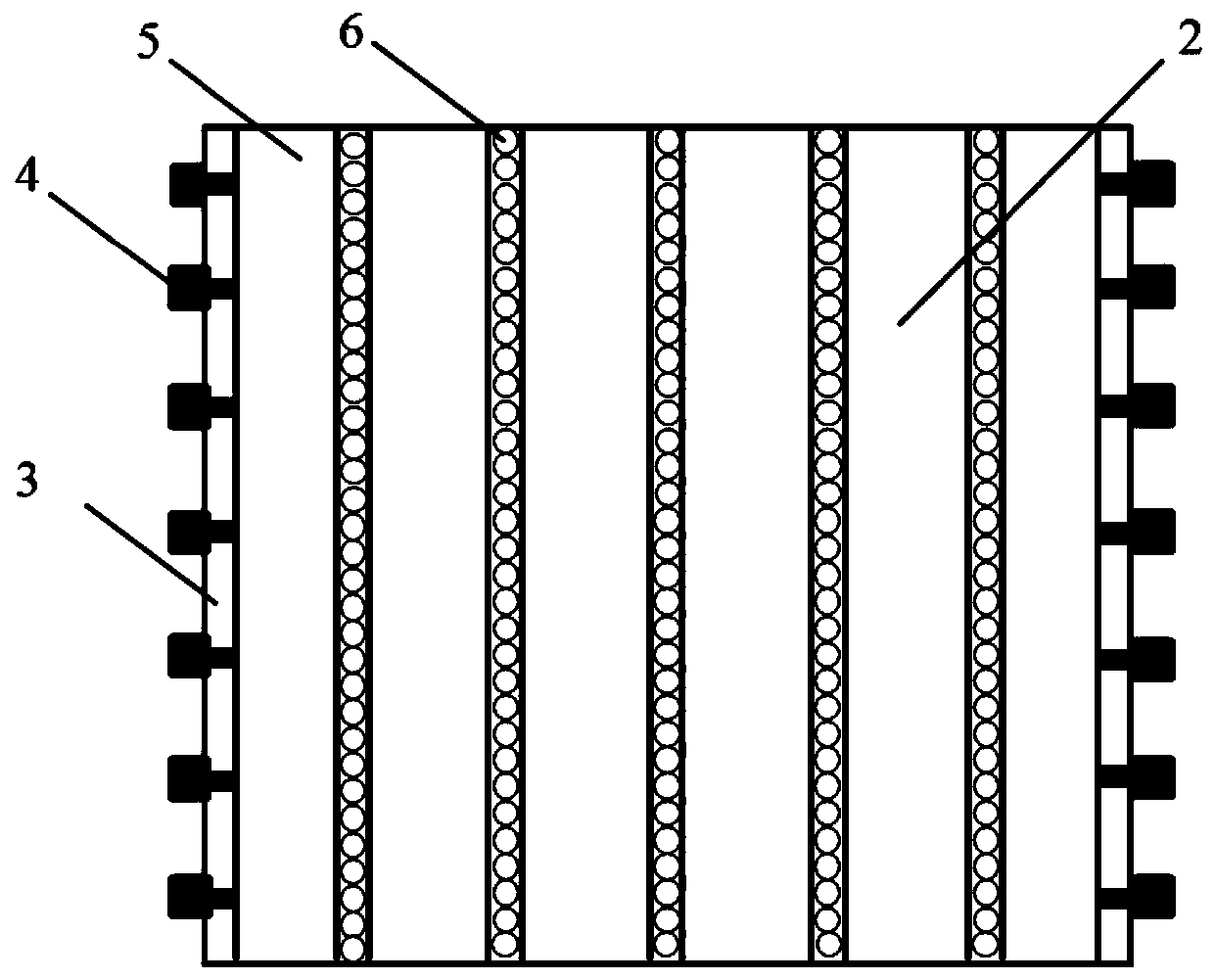

[0027] Such as figure 1 As shown, the embodiment of the present invention provides a production mold 1 for light-transmitting concrete. The mold 1 includes a bottom plate, two templates 2 and four side plates. Two formworks 2 are arranged close to the insides of the left and right side panels to form a concrete molding area. Such as figure 2 As shown, the template 2 is symmetrically provided with several pressing sheets 5, each pressing sheet compresses one layer of optical fiber, one pressing sheet, one layer of optical fiber, and so on, filling the entire mold. The pressing piece is fixed by bolts 4, and the bolt 4 passes through the steel frame pressing strips 3 at both ends of the formwork to fix the pressing piece 5 on the formwork 2. The optical fiber is compressed and fixed between the pressing sheets 5 .

[0028] The two templates 2 are arranged symmetrically, and the optical fibers 6 are arranged in layers between the pressing sheets 5 , and the thickness of the p...

Embodiment 2

[0030] The difference from Embodiment 1 is that two formworks 2 are arranged between the left and right side panels, and the distance between the two formworks 2 is greater than one-third of the distance between the left and right side panels, forming three concrete forming areas. The inner sides of the left and right side plates are provided with grooves corresponding to the positions of the optical fibers, and the ends of the optical fibers are fixed in the grooves. The width of the groove is 0.3-0.6 mm larger than the diameter of the optical fiber.

Embodiment 3

[0032] (1) Cement paste, including water, sand, cement, fly ash and water reducer, wherein the mass ratio of water, sand, cement, fly ash and water reducer is 301:1066:544:293:8.37 , the fluidity of cement paste is ≥250mm, and the density of cement mortar is 2.0-2.2g / cm 3 . The cement is P.O 42.5 grade ordinary Portland cement; the water reducer is a polycarboxylate water reducer, and the water reducing rate of the polycarboxylate water reducer is ≥ 25%; the fly ash is class F class II ash; River sand is sieved through a 2.36mm square hole sieve to remove the above part and the part below the 0.075mm square hole sieve, and the mud content is ≤1%.

[0033] (2) The optical fiber is a plastic optical fiber with a density of 0.8-1.5g / cm 3 .

[0034] (3) Make light-transmitting concrete according to the following methods:

[0035] 1) Fix the optical fiber in the mold, and it is advisable to control the fluidity of the matrix at about 300mm, so that the matrix and the optical fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com