Plate folding mechanism and automatic plate separating machine with same

A technology of a splitter and a lifting drive mechanism, which is applied in metal processing, electrical components, printed circuit manufacturing, etc., can solve the problems of large feedback stress of falling off and splitting composite boards, and high product scrapping rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention. The present invention will be described in detail below in conjunction with the accompanying drawings.

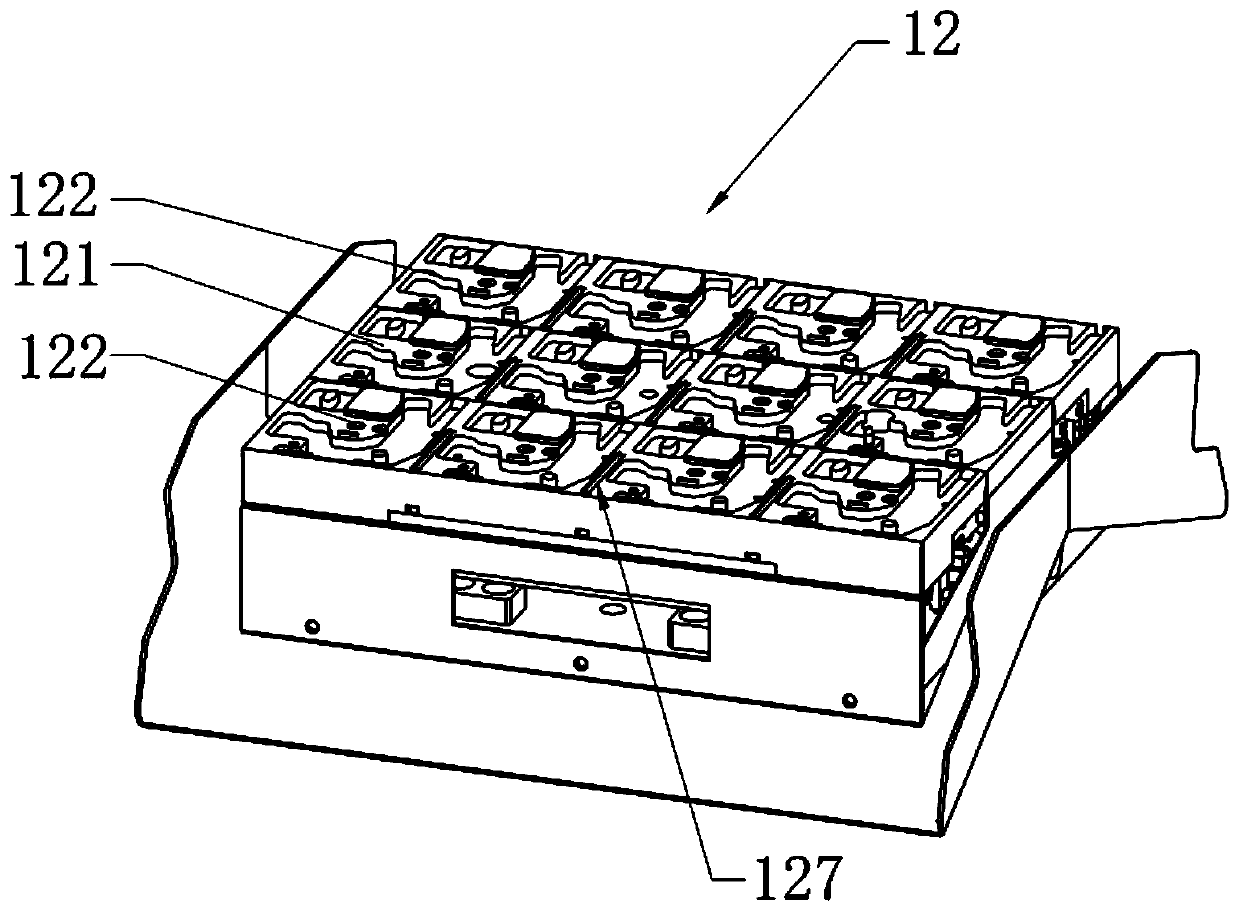

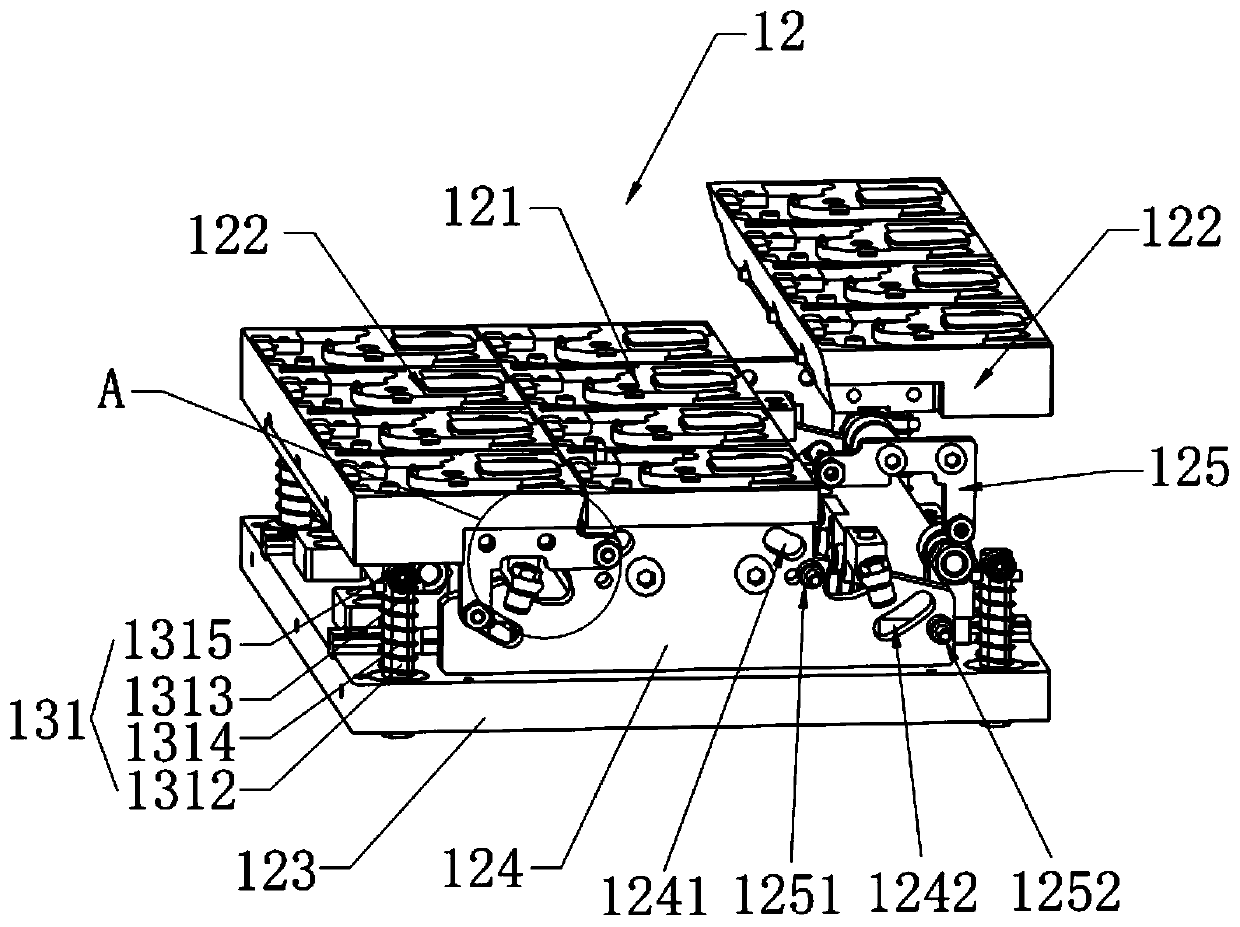

[0031] Such as Figure 1 to Figure 7 As shown, a folding plate mechanism 11 provided by the present invention includes a circuit board carrying jig 12, a first lifting plate 13 that is movably arranged above the circuit board carrying jig 12, and a mechanism for driving the first lifting plate 13 to lift. The first lifting drive mechanism 132, the first lifting plate 13 is provided with a first clamping plate 136, and the two sides of the first clamping plate 136 are respectively provided with two side lower pressure blocks 133 and are used to drive the side. The first lifting drive member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com