A kind of microbial seed pelletized coating composition

A technology of pelletization and composition, which is applied in the field of seed coating coating agents, can solve the problems of short residual period of biological insecticides, etc., to prolong the duration and residual period, ensure germination ability, and prolong nutrition The effect of growth period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Seeds tested: Rapeseed

[0022] Seed pelleting process: seed selection (de-horning or grinding)→seed disinfection→wetting with adhesive→mixing with medicament or auxiliaries→adding filler and stirring→pellet forming→hot air drying→screening and grading according to particle size→ Quality inspection → quality weighing → bagging → storage, the invention adopts the rolling granulation method, and utilizes the rotary seed pelletizing machine. The specific steps are: put the selected seeds into the horizontal drum, and the seeds follow the Spray the adhesive while rolling continuously so that the seeds do not stick to each other and maintain a certain humidity on the surface, then add the starch evenly mixed with the Bacillus subtilis powder and spray the plant growth regulator, then add the filler, and send it into the Dry in drying equipment.

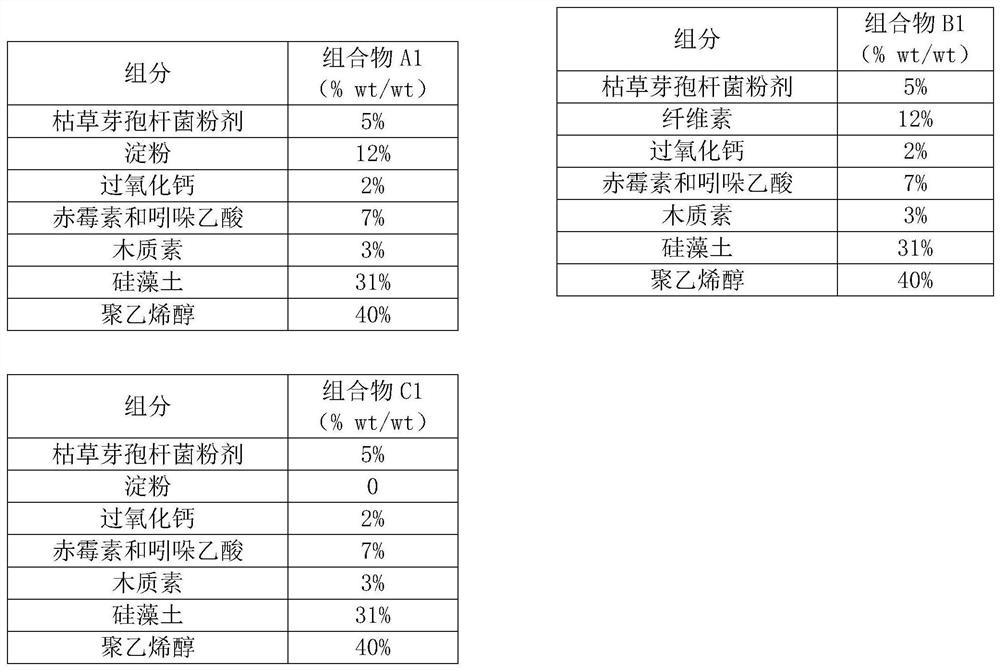

[0023] The coating composition formulations were prepared according to Table 1, composition A1 was the experimental group, and bo...

Embodiment 2

[0027] Test seeds and seed pelletization process flow are all the same as in Example 1.

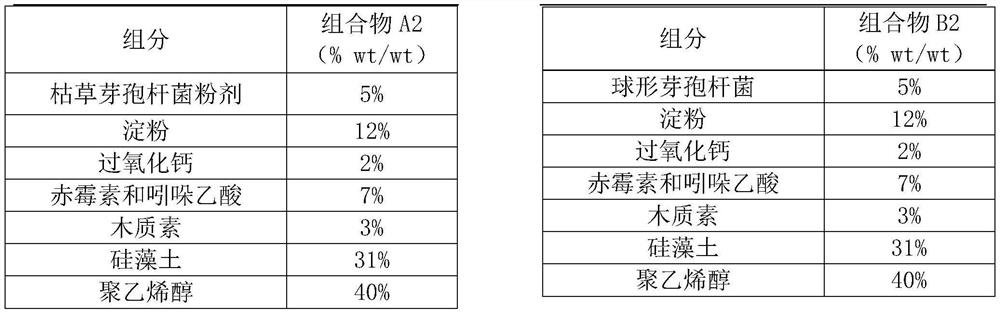

[0028] The coating composition formulations were prepared according to Table 2, composition A2 was the experimental group, and both composition B2 and composition C2 were control groups.

[0029] Table 2:

[0030]

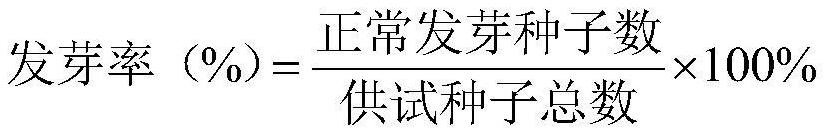

[0031] The germination ability of seeds is measured by germination on a sand bed. The pelleted seeds are placed in a 12cm×12cm×6cm small germination box covered with fine sand, and gently pressed into the sand bed with your fingers to make it just submerged in the sand. , each formula has 3 repetitions, 50 seeds per repetition, keep the room temperature around 25℃, and give 12h of light every day for germination determination. Observe and count the number of germinations every day (with the cotyledons exposed as a standard), count the germination potential after the test starts 3d, count the germination rate after 7d, the germination rate and the germination potential resu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com