Vibration system, control method and electronic equipment of a linear motor group

A linear motor and vibration system technology, applied in the field of electronic equipment and linear motor group vibration system, can solve the problems of vibration attenuation, motor vibration intensity reduction, cost increase, etc., to achieve the effect of increasing vibration intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] see Figure 1~Figure 4 , an embodiment of the present invention provides a control method for a vibration system of a linear motor group.

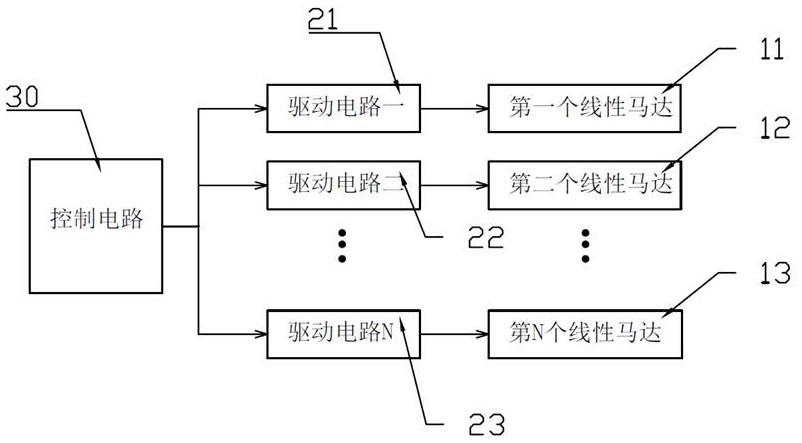

[0031] As shown in FIG. 1 , the linear motor group vibration system includes a drive circuit, a control circuit 30 and a linear motor group. The vibration part of the vibration system is a linear motor group, the linear motor group includes a plurality of linear motors, the number of linear motors is N, and N>=2. The linear motor group includes a first linear motor 11 and a second linear motor 12 . . . Nth linear motor 13 . The control circuit 30 and the drive circuit are a control section. The control circuit 30 is electrically connected to the linear motor group, and the driving circuit is electrically connected to the control chip.

[0032] The number of drive circuits is the same as the number of linear motors, and the number is also N. The drive circuits include drive circuit one 21 and drive circuit two 22 . . . Drive...

Embodiment 2

[0052] This embodiment provides a linear motor group vibration system. The vibration system includes a driving circuit, a control circuit 30 and a linear motor group. The control circuit 30 is electrically connected to the linear motor group, and the driving circuit is electrically connected to the control chip. The number of linear motors in the linear motor group is N>=2, the number of drive circuits is the same as the number of linear motors, and the control circuit 30 is electrically connected to the N drive circuits at the same time. The control method of the vibration system of the linear motor group is as described in the first embodiment.

[0053] The vibration system includes a driving chip and a control chip. The driving chip is provided with N driving circuits, and the control chip is provided with a control circuit 30 . The control chip is electrically connected to the linear motor group, and the driving chip is electrically connected to the control chip. The dr...

Embodiment 3

[0055] The present invention also provides an electronic device, the electronic device includes a display module, and the electronic device further includes a linear motor group vibration system as described in the second embodiment. The linear motor group of the linear motor group vibration system is generally arranged on the back of the display module, for example, connected by means of gluing or bracket fixed connection. The linear motor group works under the operation of the control circuit and the driving circuit, so that the display module can obtain sufficient vibration.

[0056] Specifically, the display module includes a touch screen and a display screen. The display module is an existing display module in the field, and details will not be repeated here.

[0057] Compared with the prior art, the beneficial effects of the present invention are as follows:

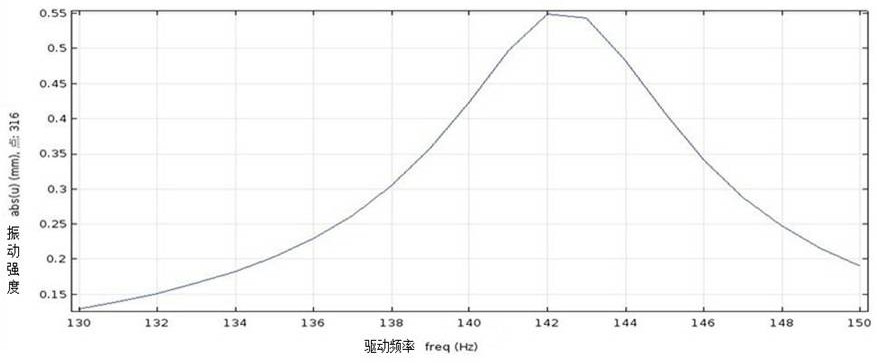

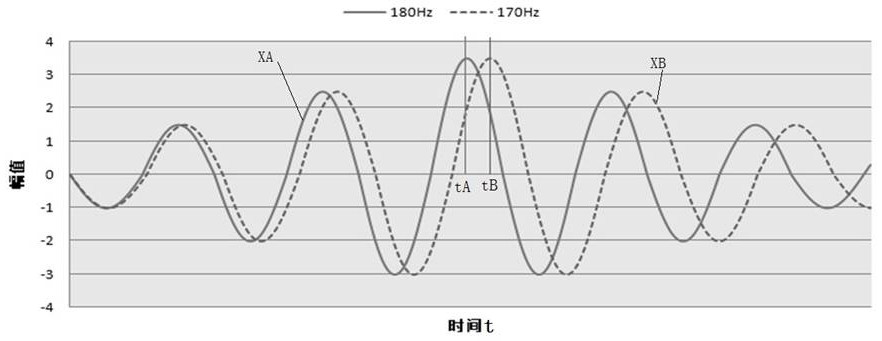

[0058] The present invention uses the drive circuit to drive the corresponding linear motor with the resonant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com