Micro vibration motor with convenient assembly of balance weight blocks

A vibrating motor and a convenient assembly technology, which is applied in the direction of electromechanical devices, electric components, and the manufacture of motor generators, etc., can solve the problems of alignment and positioning, the inability to insert and rotate the main shaft of the eccentric block, and restrict the degree of automatic assembly, etc., to improve assembly The effect of efficiency and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

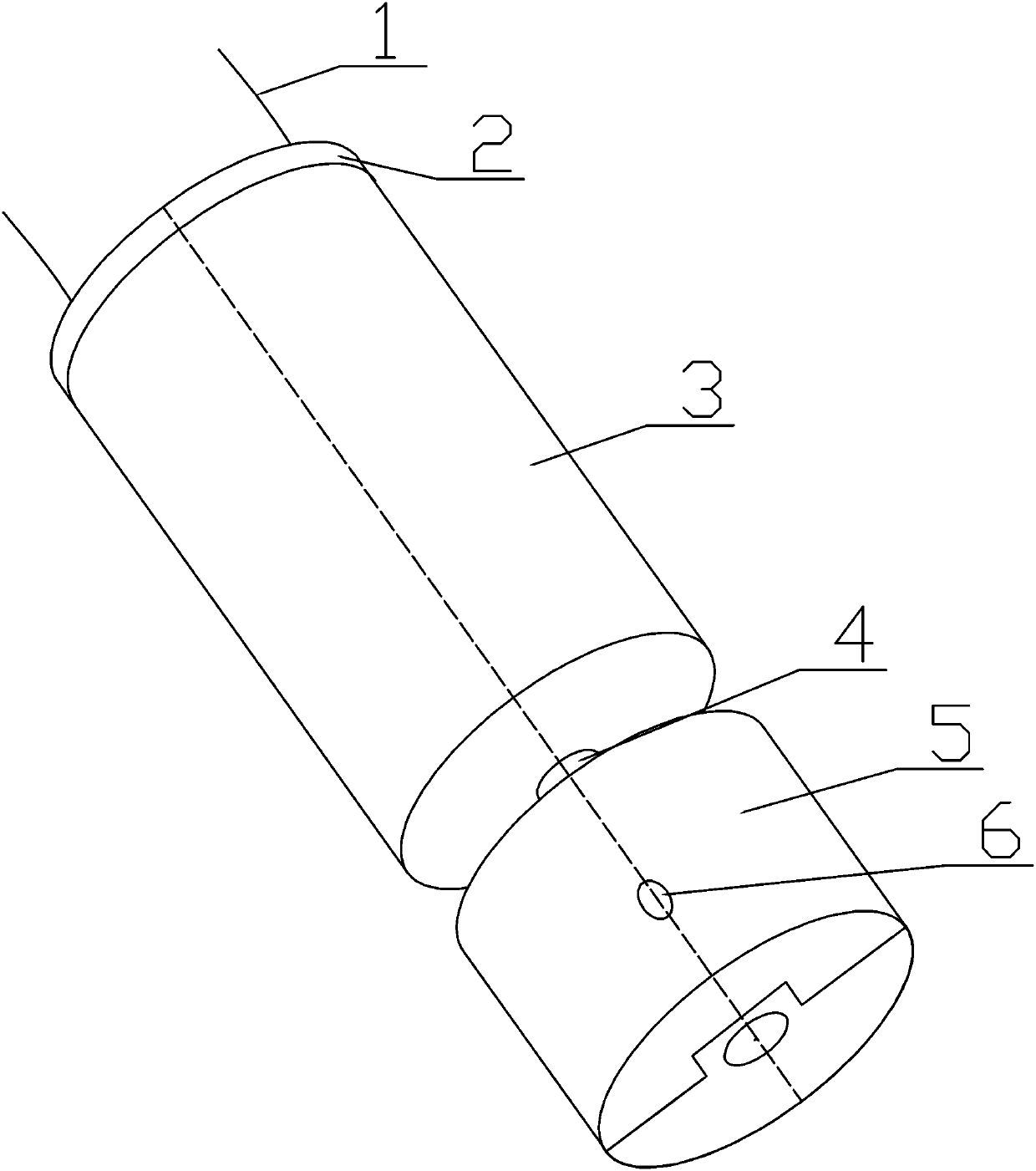

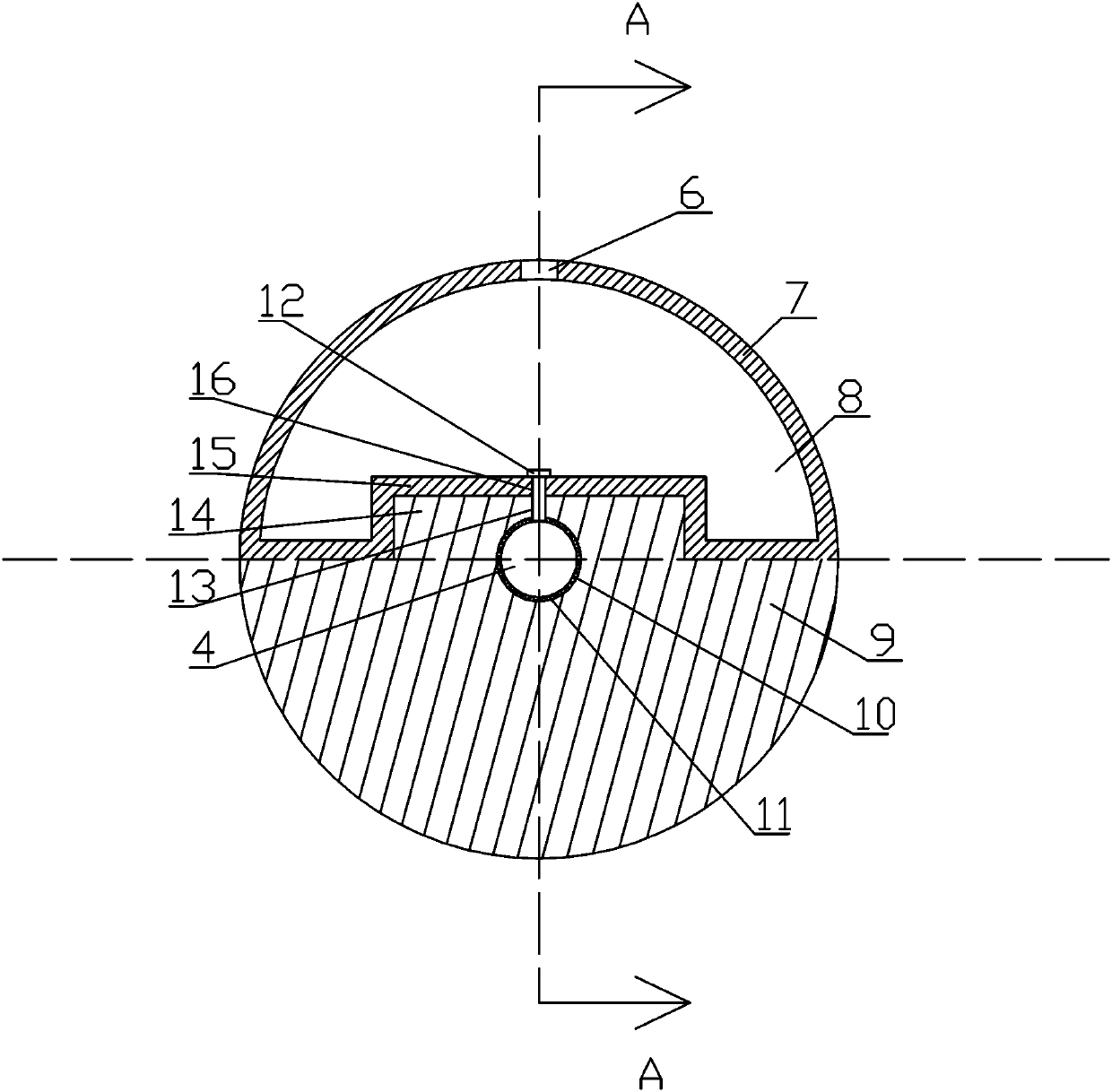

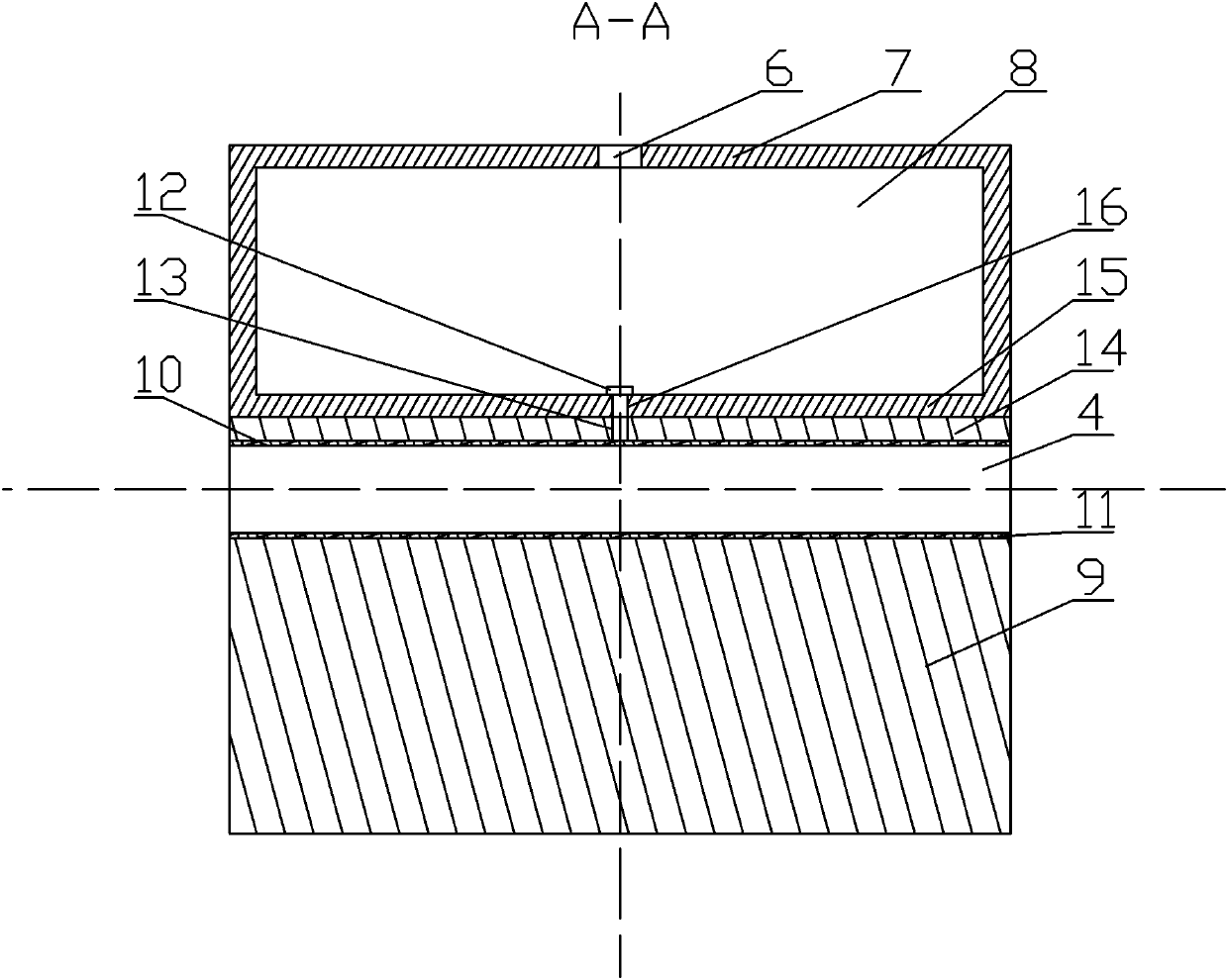

[0024] see Figure 1-4 , a miniature vibrating motor that is convenient to assemble and assemble weights, it includes a motor body 3, a rear cover 2 is installed at the tail of the motor body 3, a power cord 1 is connected to the rear cover 2, and a main shaft 4 of the motor body 3 A combined counterweight 5 is installed on it; the combined counterweight 5 includes a hollow counterweight 7, and the hollow counterweight 7 and the solid counterweight 9 are combined to form an integral cylindrical counterweight structure. By adopting the above-mentioned miniature vibrating motor, it is possible to facilitate the assembly of the combined counterweight, thereby adapting to an automatic assembly line and improving its assembly efficiency.

[0025] Further, the inside of the hollow weight 7 is provided with a hollow body 8, a top through hole 6 is processed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com