Sleeve assembly used for installing ballistic correction fuse in fixed rudder ballistic correction fuse semi-physical simulation system

A semi-physical simulation, ballistic technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as no guidance plan is given

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

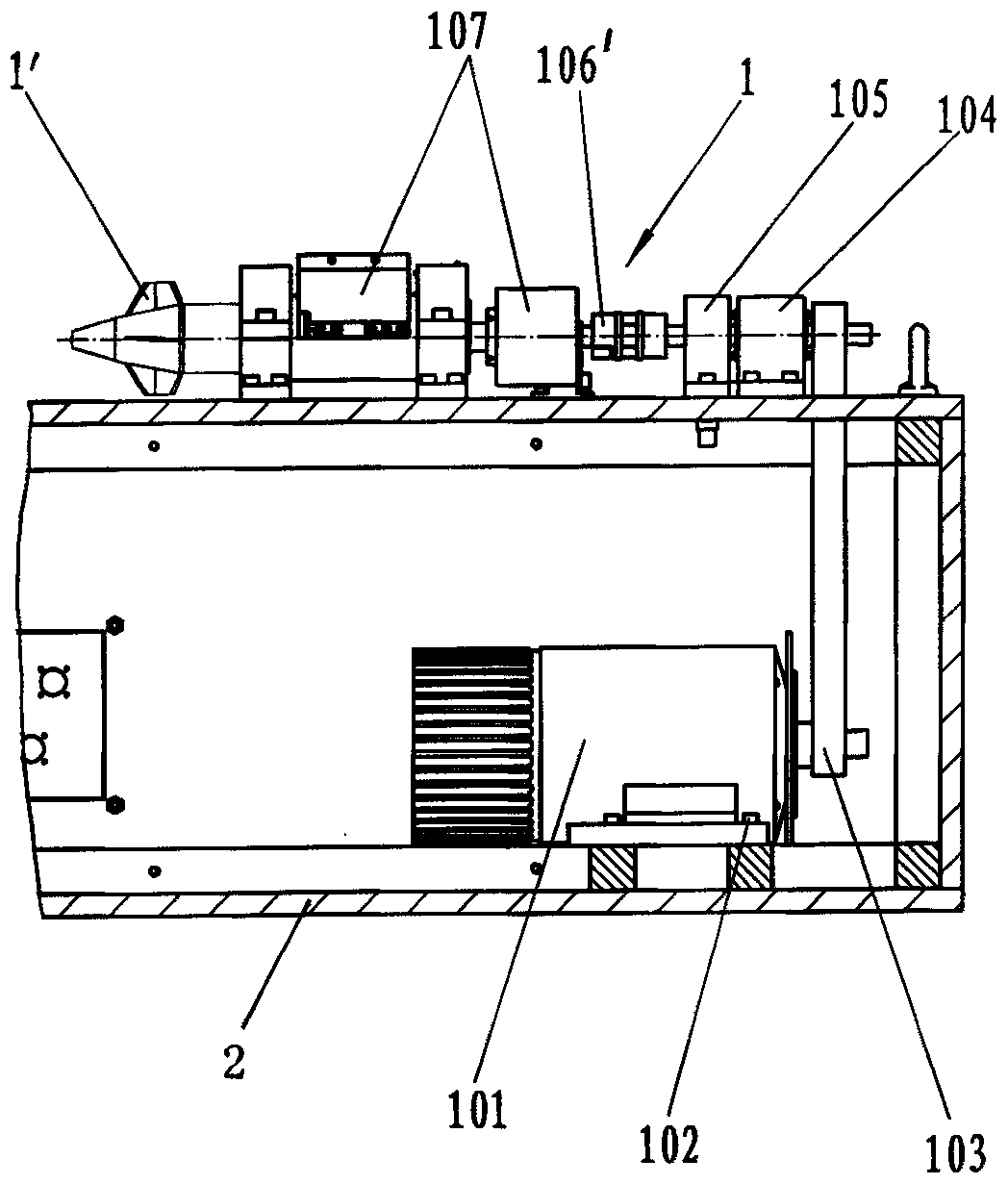

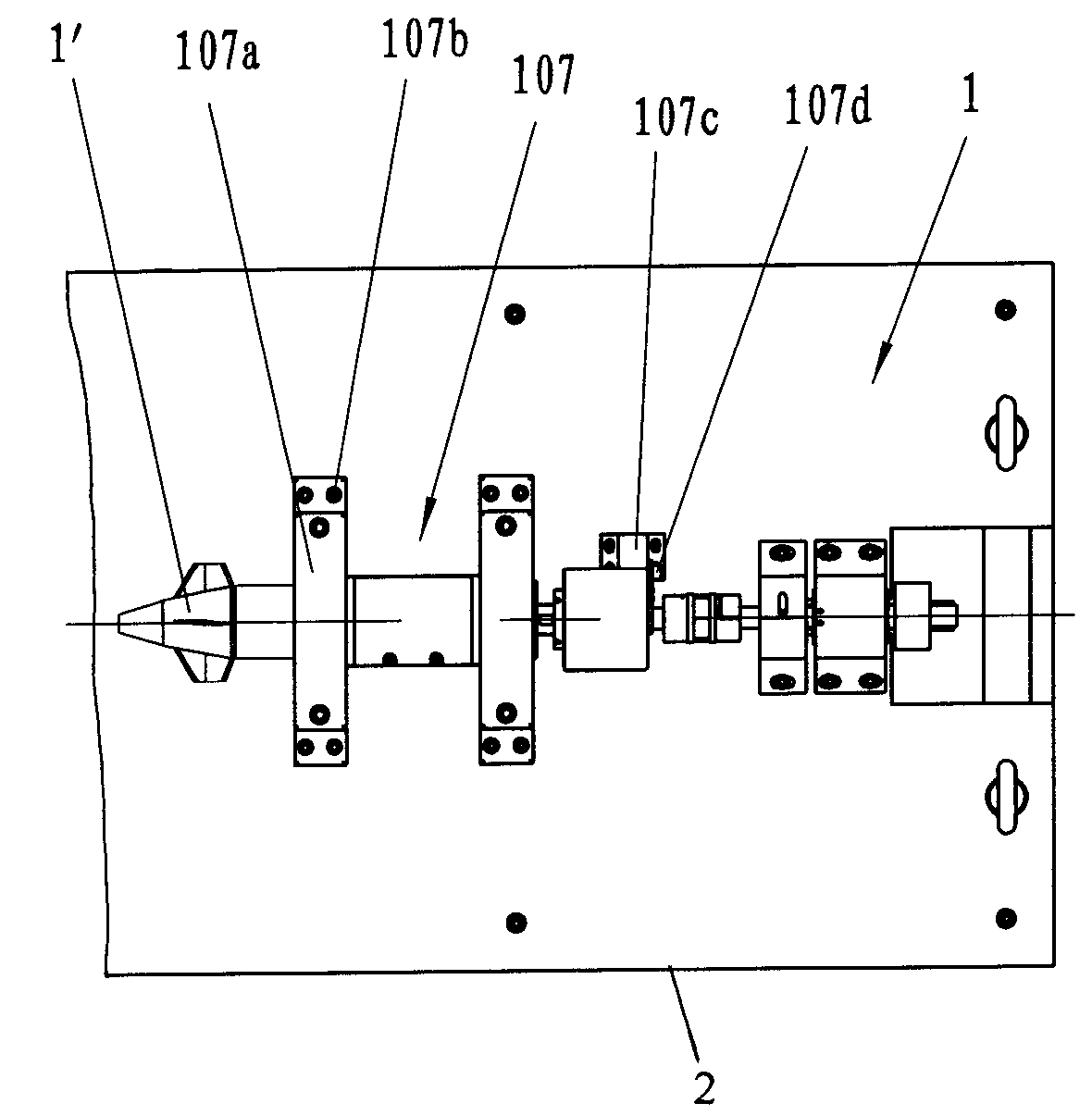

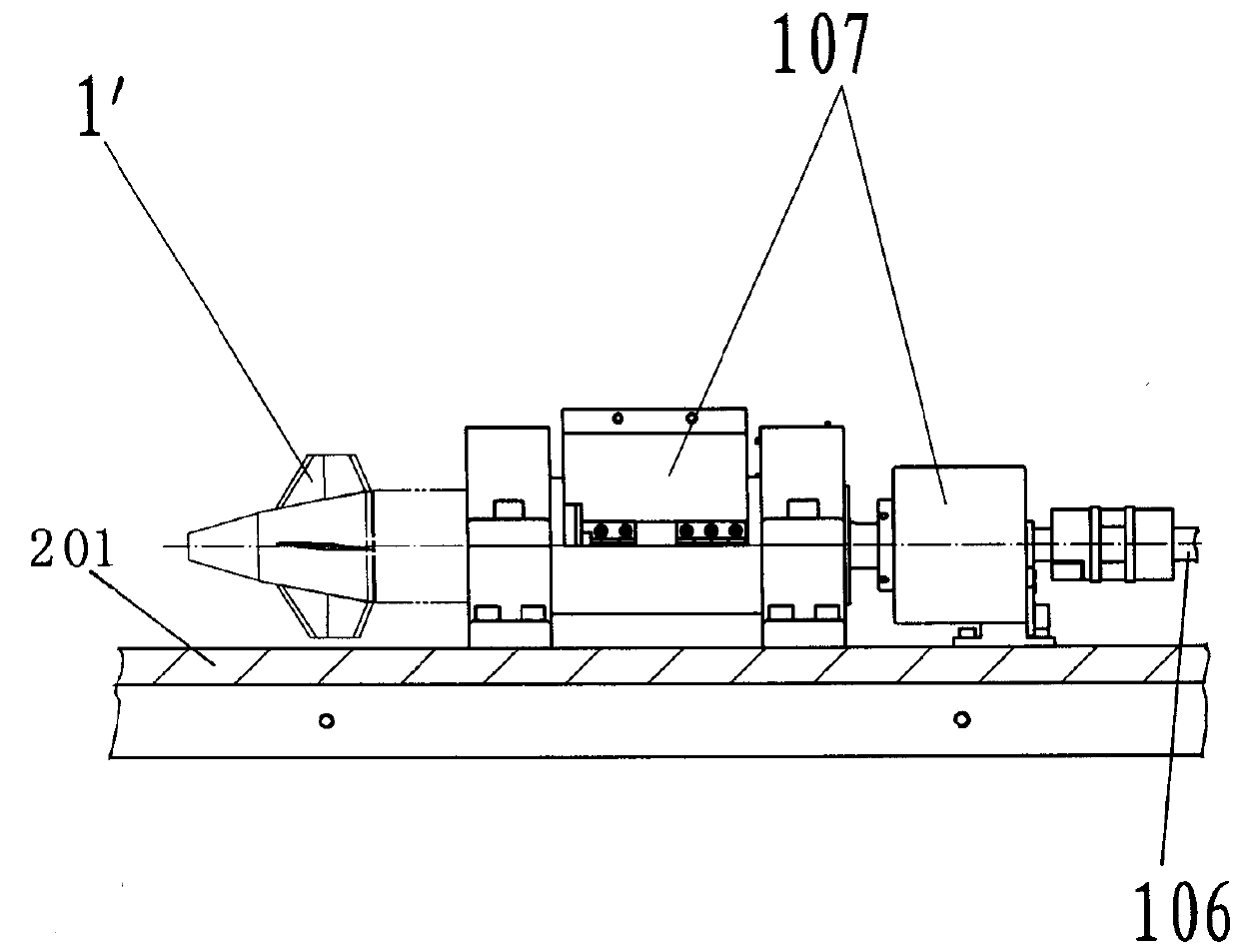

[0020] Embodiment 1: as figure 1 , figure 2 , image 3 As shown, the present invention is installed in the projectile rolling simulation measurement system 1, and the projectile rolling simulation measurement system 1 has a box body 2, a motor 101, a hexagon socket head screw 102 on the base of the fixed motor, a synchronous pulley and a synchronous belt 103, bearing housing 104, rotational speed velocimeter 105, sleeve assembly for installing ballistic correction fuze (namely the present invention), simulation computer (simulation machine, computer for simulation, computer simulation), controller, cable (and display equipment, etc.). The box body 2 has a panel 201 , and the panel 201 is located on the upper end surface of the box body 2 . The ballistic correction fuze 1' is installed on the sleeve assembly for installing the ballistic correction fuze.

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7As shown, the sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com