Rotary clamping mechanism

A clamping and rotating body technology, applied in the field of rotating clamping mechanism, can solve the problems of large size and shape of the motor, increase in cost, dependence, etc., and achieve the effect of flexible bidirectional or unidirectional rotation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several changes and improvements without departing from the concept of the present invention. These all belong to the protection scope of the present invention.

[0050] basic embodiment

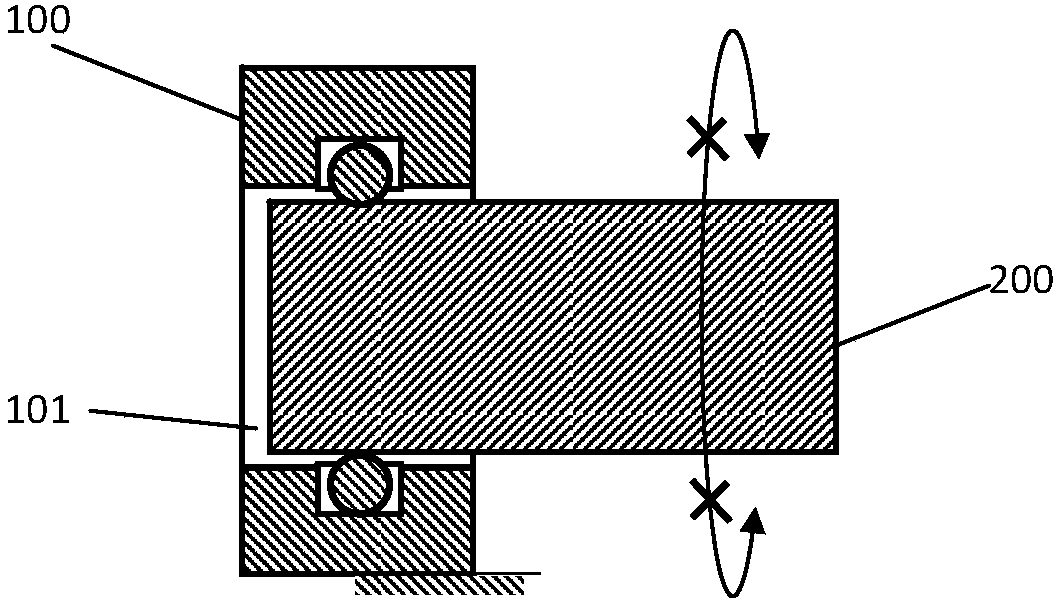

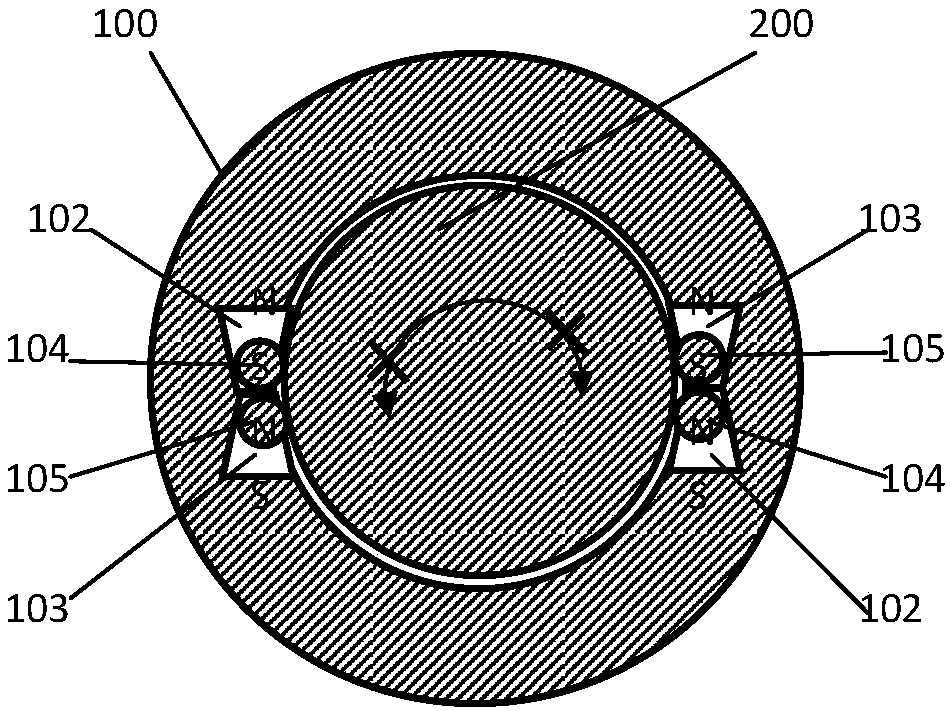

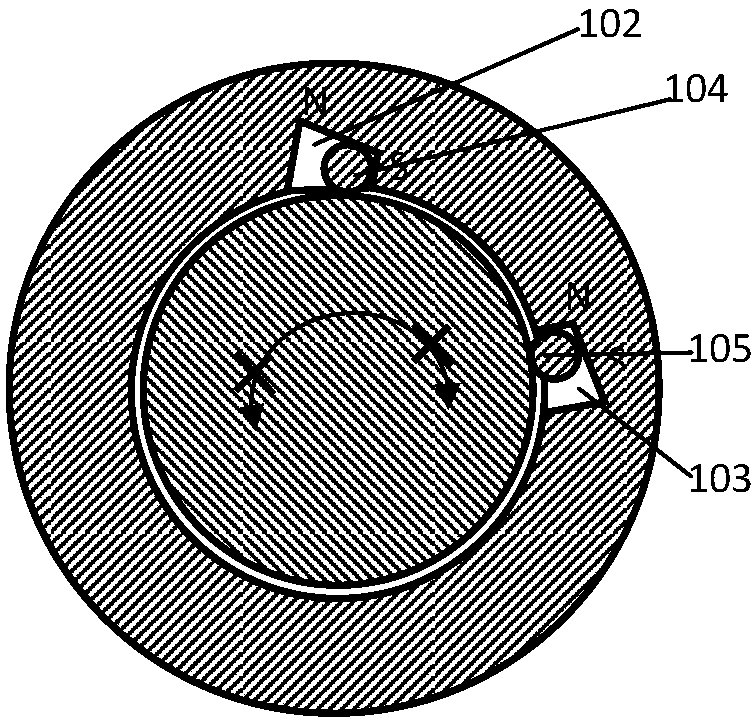

[0051] like figure 1 Shown is a basic embodiment.

[0052]A rotation clamping mechanism provided according to the present invention includes a rotation controllable stopper 100 and a rotation body 200;

[0053] The rotation controllable stopper 100 has a rotation body receiving hole 101;

[0054] The rotating body 200 is inserted into the rotating body receiving hole 101;

[0055] In the circumferential rotation direction of the rotating body 200 , the rotation controllab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com