Auxiliary mounting device for prestressed steel strand penetrating end

A prestressed steel strand and installation device technology, which is applied in the direction of roads, tracks, road repairs, etc., can solve the problems of low beam penetration efficiency, high friction, and difficulty in straightening the steel strand, and achieve a compact drive structure and increased The effect of the factor of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

[0030] In conjunction with the accompanying drawings.

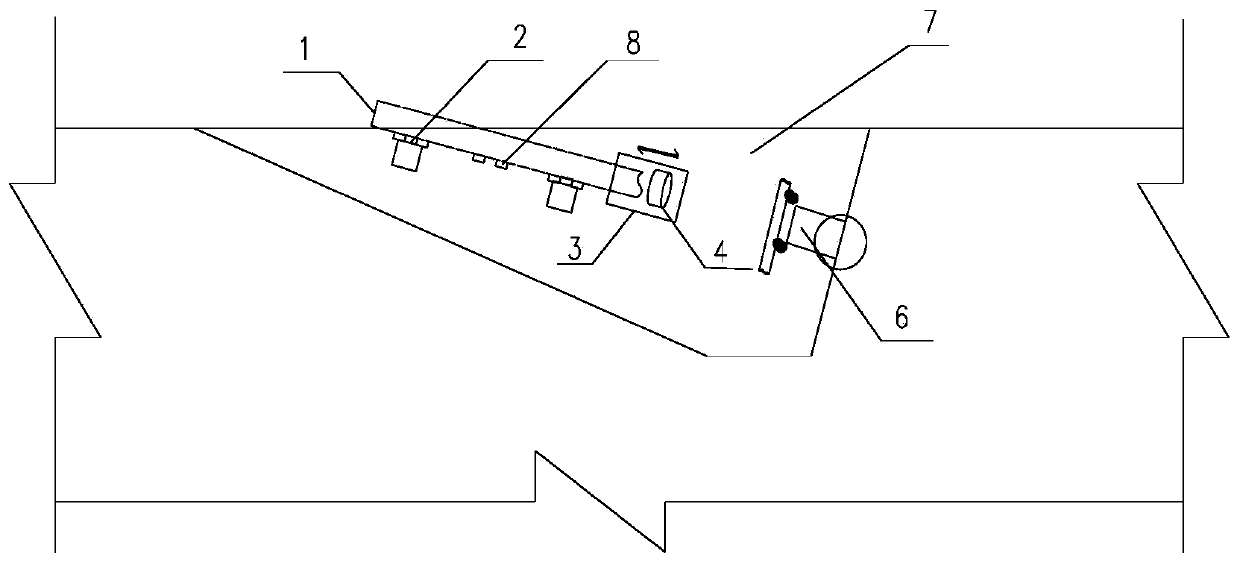

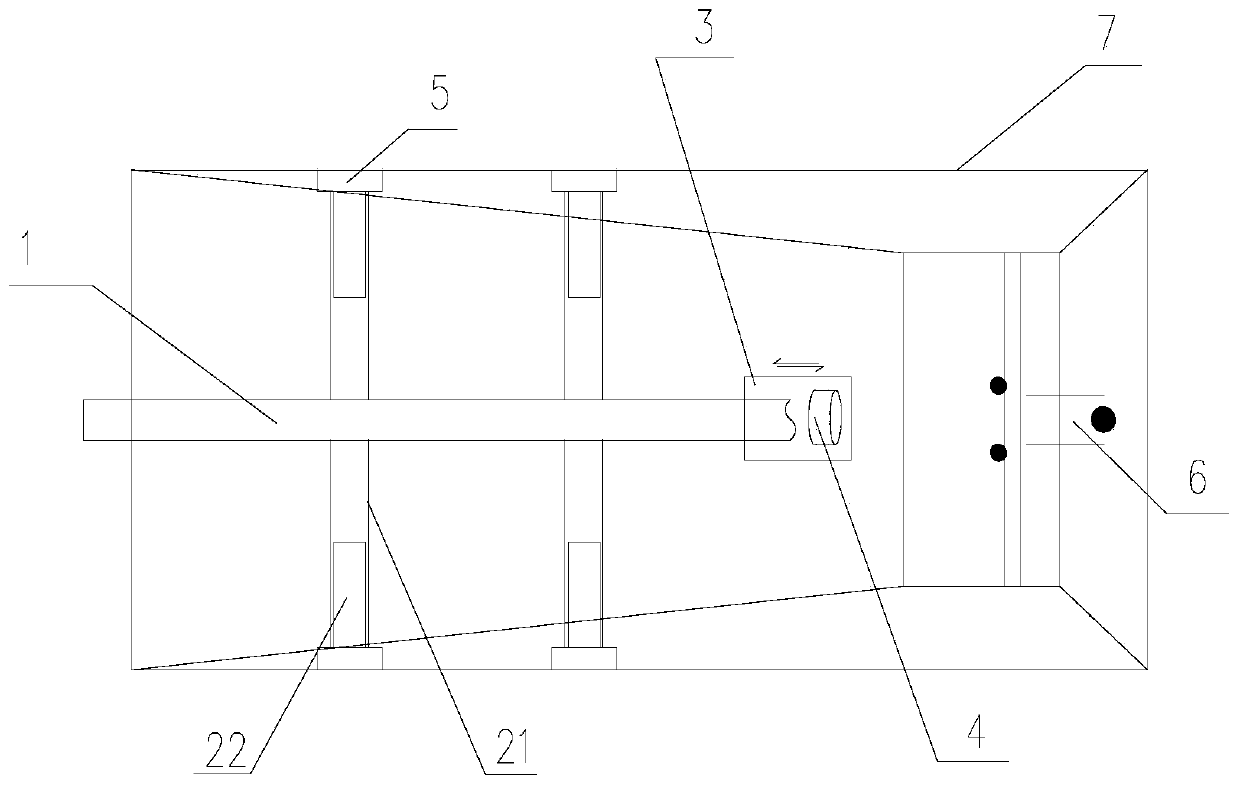

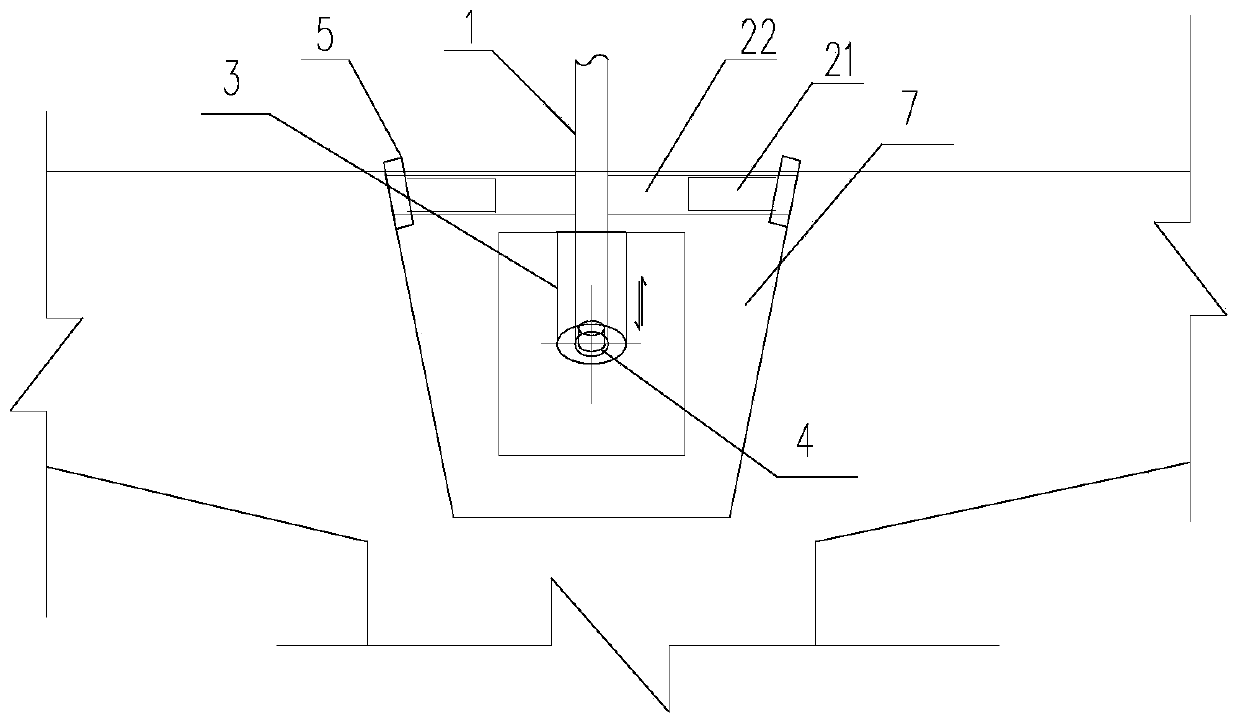

[0031] The auxiliary installation device for the threading end of the prestressed steel strand includes a longitudinal sliding system for clamping and fixing the threading end of the steel strand 9 and completing the movement, and a horizontal adjustment system for supporting and adjusting the longitudinal sliding system;

[0032] The lateral adjustment system includes multiple groups of lateral adjustment devices 2 arranged laterally between the groove walls along the installation groove 7 of the steel strand 9; each group of lateral adjustment devices...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com