Ultrasonic C-scan automatic detecting system

An automatic detection, ultrasonic technology, applied in the direction of material analysis, measurement device, instrument, etc. using sonic/ultrasonic/infrasonic waves, can solve the left and right drift of surface echo, large workpiece clamping error, axial runout and The radial runout cannot meet the requirements, etc., to achieve the effect of high precision, suppression of agitation, and avoidance of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

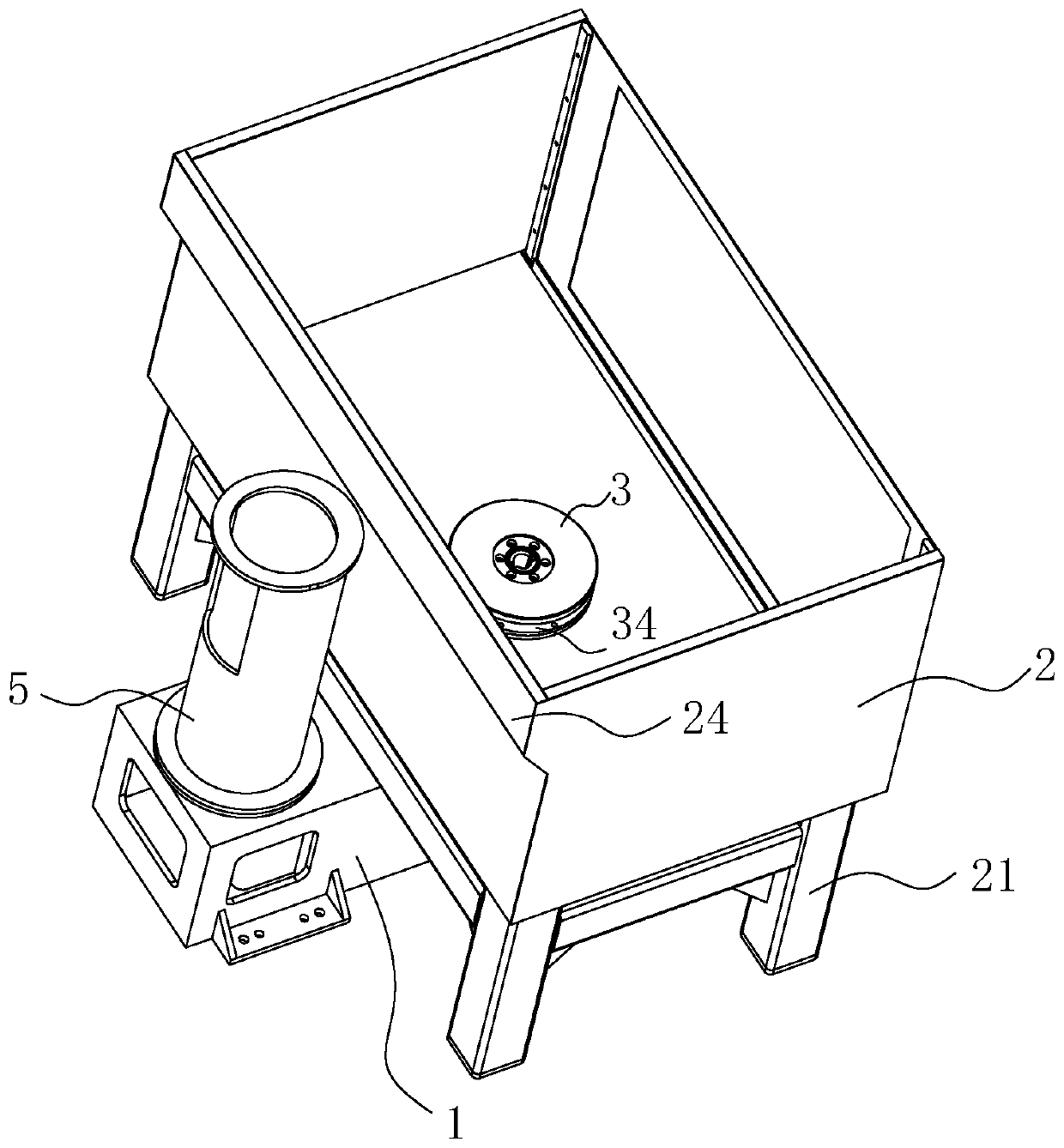

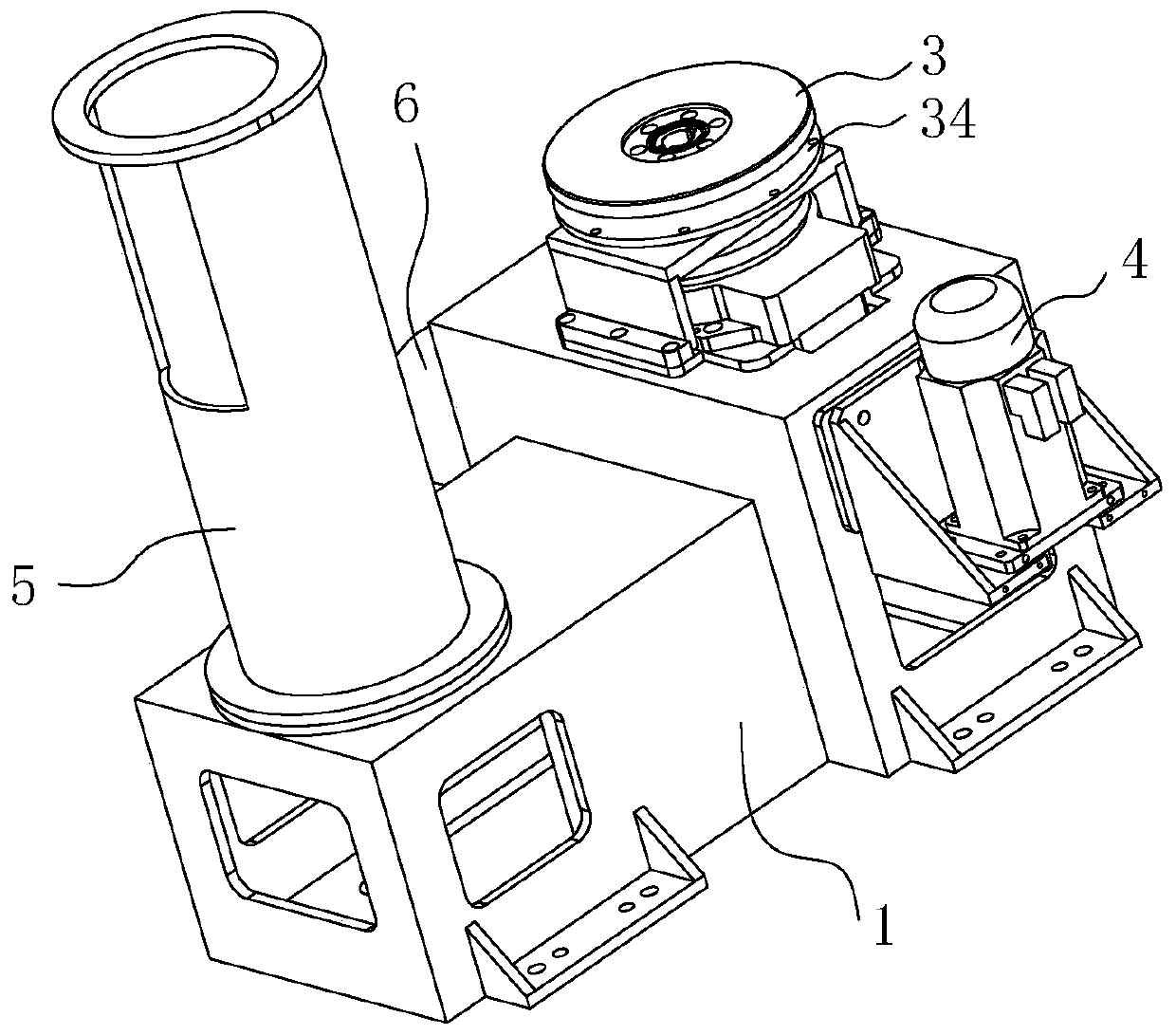

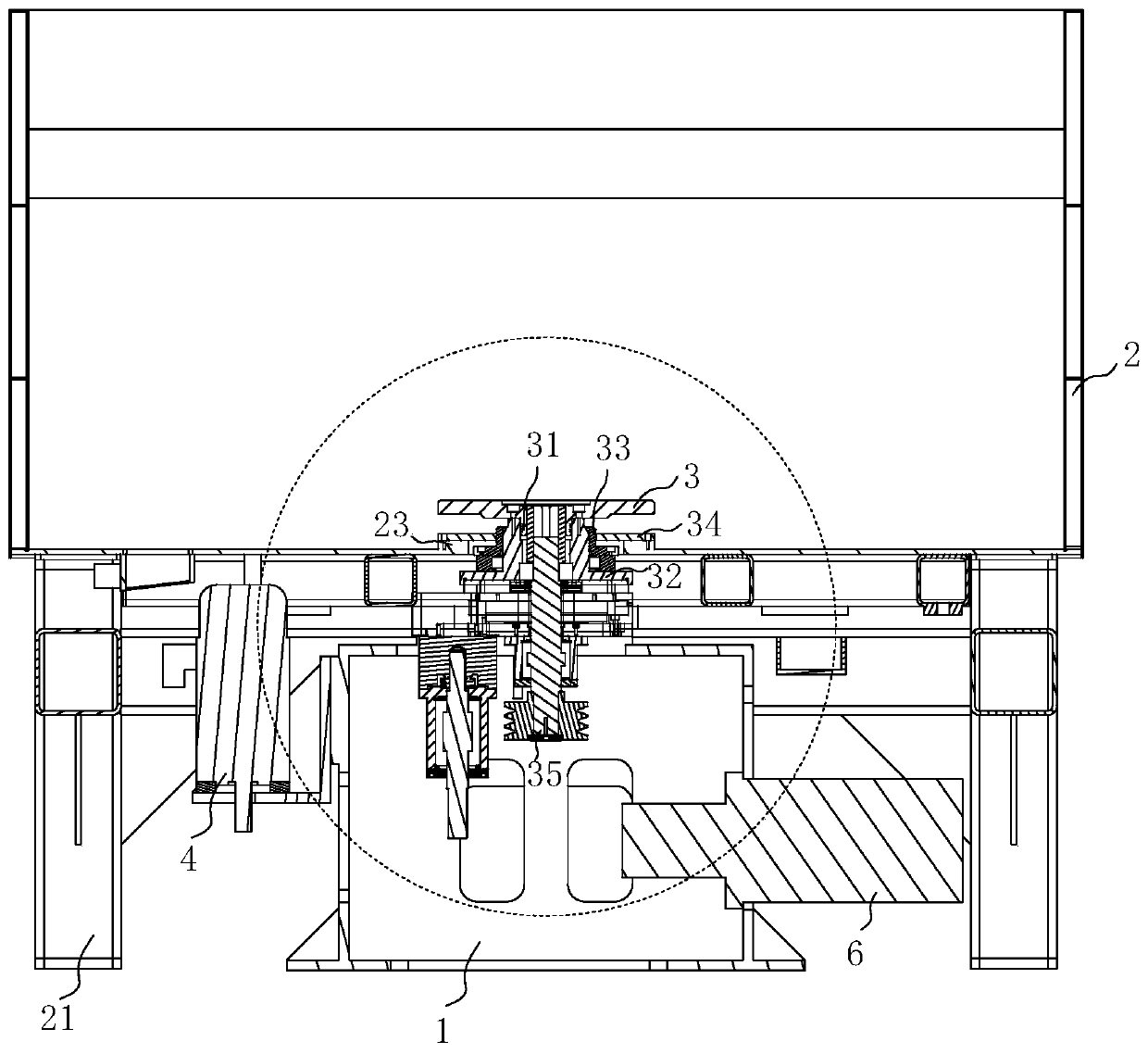

[0023] refer to Figure 1 to Figure 5 As shown, this preferred embodiment provides an automatic ultrasonic C-scan detection system, including a first base 1, an industrial robot (only partially shown) located on the first base 1, a water tank 2, for supporting The second base 21 of the water tank 2 and the turntable 3 arranged inside the bottom of the water tank 2 .

[0024] In this technical solution, the turntable 3 is fixed by the first base 1, and the water tank is fixed by the second base 21. The first base 1 and the second base 21 are set independently of each other, and the second base 21 is erected on the second base. On a base 1, and the first base 1 is independently supported on the bottom surface by foot bolts, and the second base 21 is also independently supported on the bottom surface.

[0025] In this preferred embodiment, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com