A dual-temperature refrigeration system and its control method

A technology of refrigeration system and control method, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., and can solve the problems of low refrigeration efficiency cycle performance coefficient and restricted application, so as to improve suction pressure, flexible application scenarios, and improve system Effect of volumetric cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

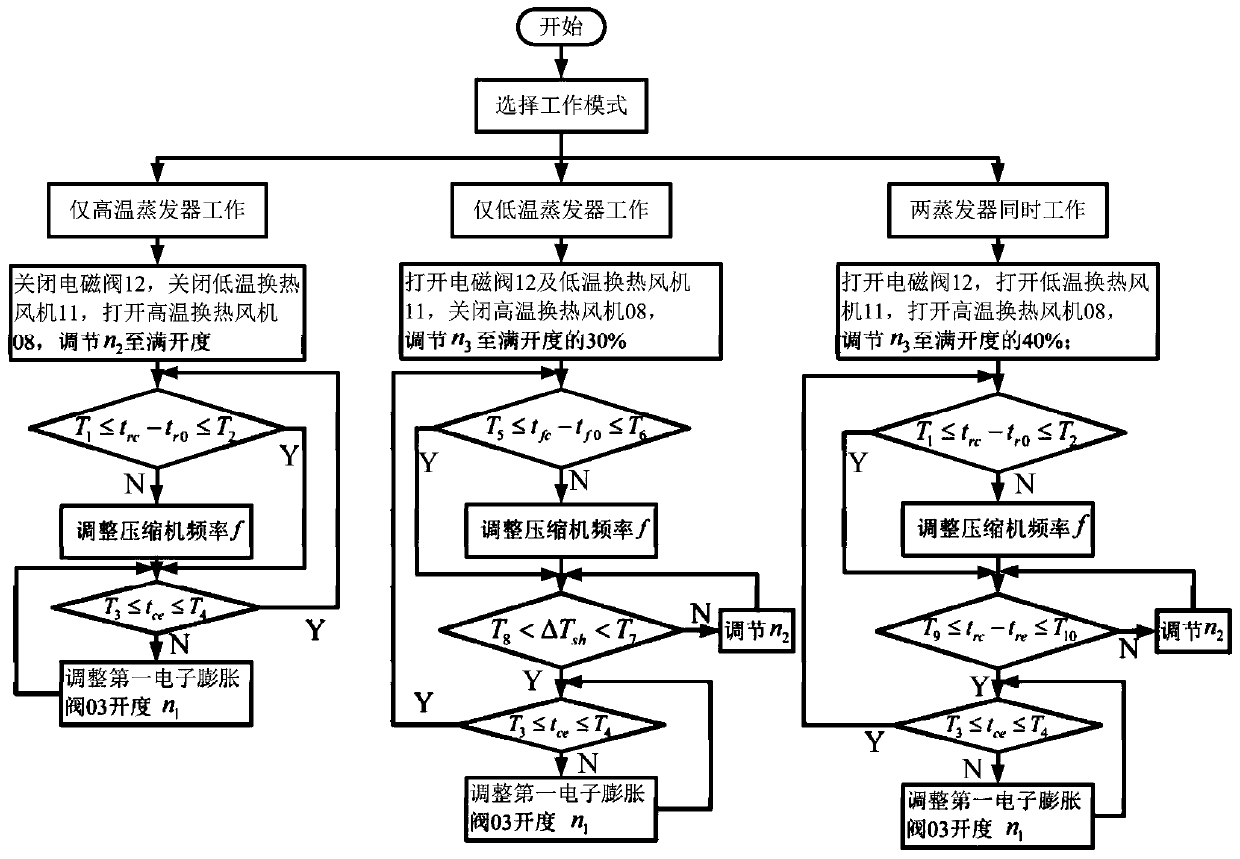

[0032] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

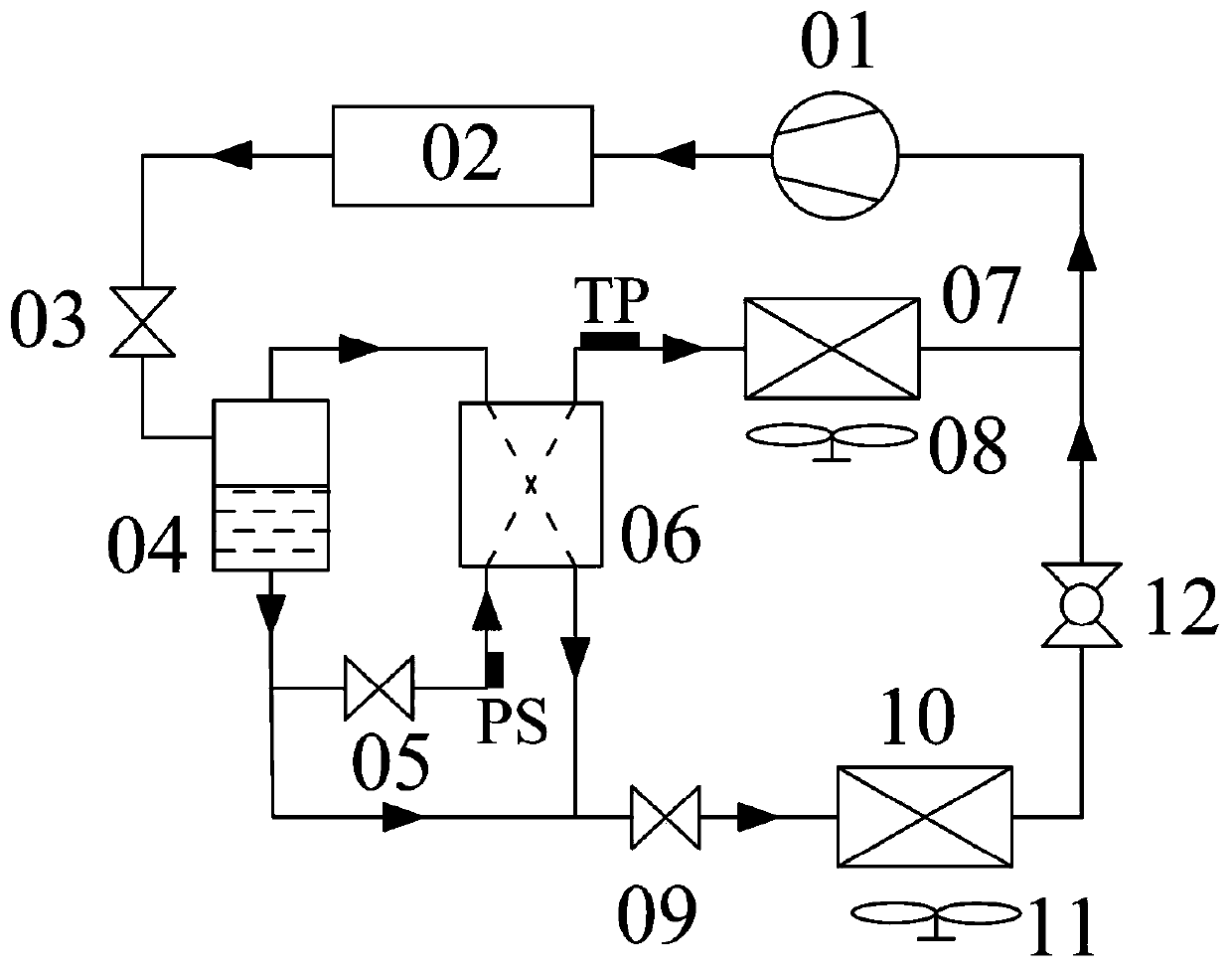

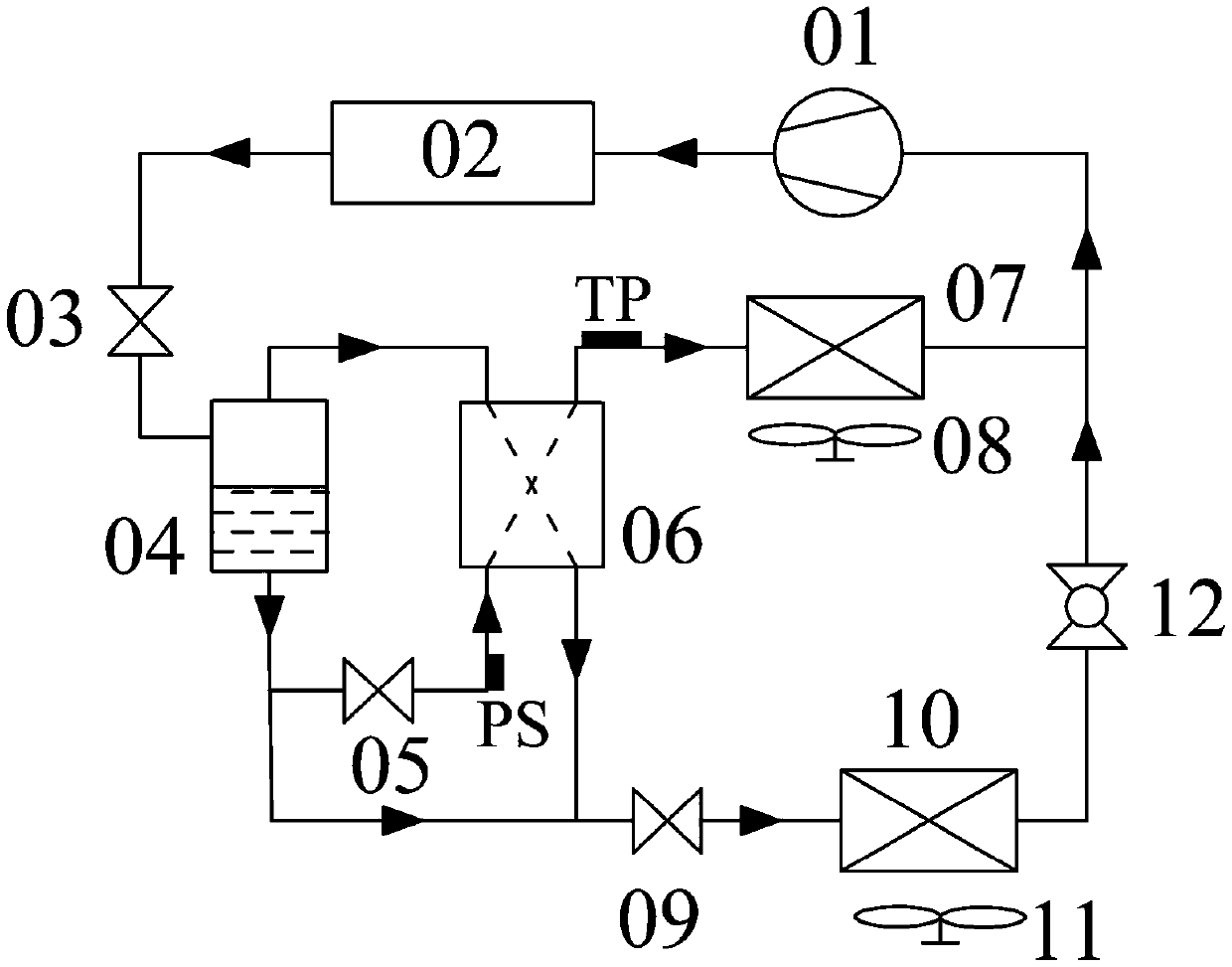

[0033] Such as figure 1 As shown, the dual-temperature refrigeration system of the present invention adopts a binary non-azeotropic mixed working medium, and the high-temperature and high-pressure gas-phase refrigerant compressed by the compressor 01 enters the condenser 02 to condense and be supercooled; the supercooled refrigerant is passed through The first electronic expansion valve 03 throttles and enters the gas-liquid separator 04. The refrigerant realizes component separation in the gas-liquid separator 04. The gas-phase refrigerant is rich in low-boiling point refrigerant, and the liquid-phase refrigerant is rich in high-boiling point refrigerant. ; After the gas-phase refrigerant flows out through the gas-phase outlet of the gas-liquid separator 04, it enters the cascade heat exchanger 06 to be completely condensed and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com