A vacuum packaging process

A vacuum packaging and process technology, which is applied in decorative arts, processes for producing decorative surface effects, metal material coating processes, etc. Expensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

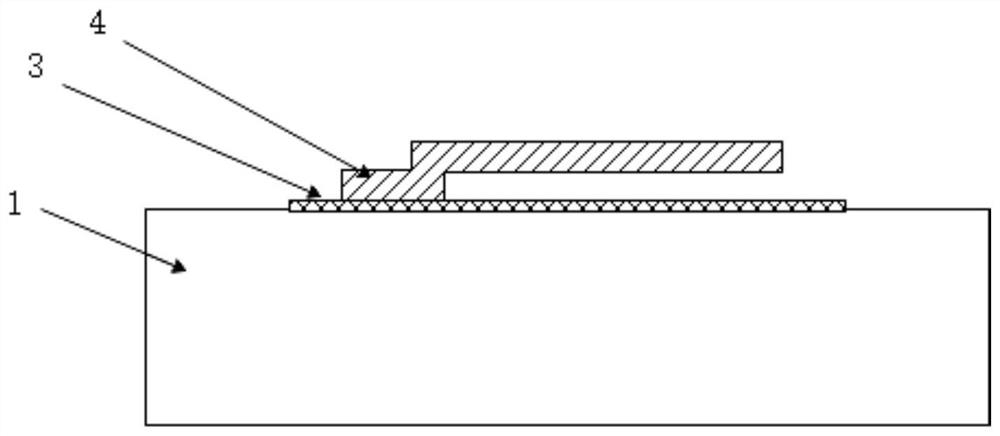

[0031] The vacuum encapsulation process according to the present invention includes: fabricating structures or devices requiring vacuum encapsulation on silicon wafers or glass wafers. According to a preferred embodiment of the present invention, a sensitive movable structure 4 is made on a silicon wafer 1, which is connected to the silicon wafer 1 through an insulating layer 3, such as figure 1 shown. The sensitive movable structure 4 can be fabricated by using conventional MEMS technology, and will not be repeated here. It should be understood that the insulating layer 3 can also be omitted.

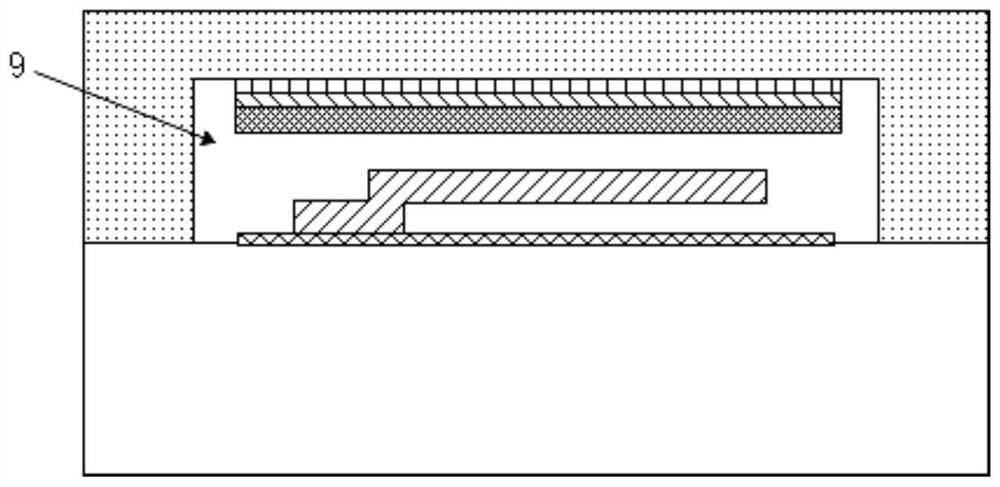

[0032] The vacuum packaging process according to the present invention includes: making an open groove on a glass wafer or a silicon wafer and a metal layer located in the groove. In the present embodiment, groove 5 is made on glass wafer 2, as figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com