Refueling gun and refueling equipment

A fueling gun and equipment technology, applied in special dispensing devices, packaging, dispensing devices, etc., can solve the problems of affecting the refueling operation, increasing the frictional resistance between the sealing ring and the shaft sleeve, and the short life, so as to improve the use feeling and reduce the Effects of frictional resistance and life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

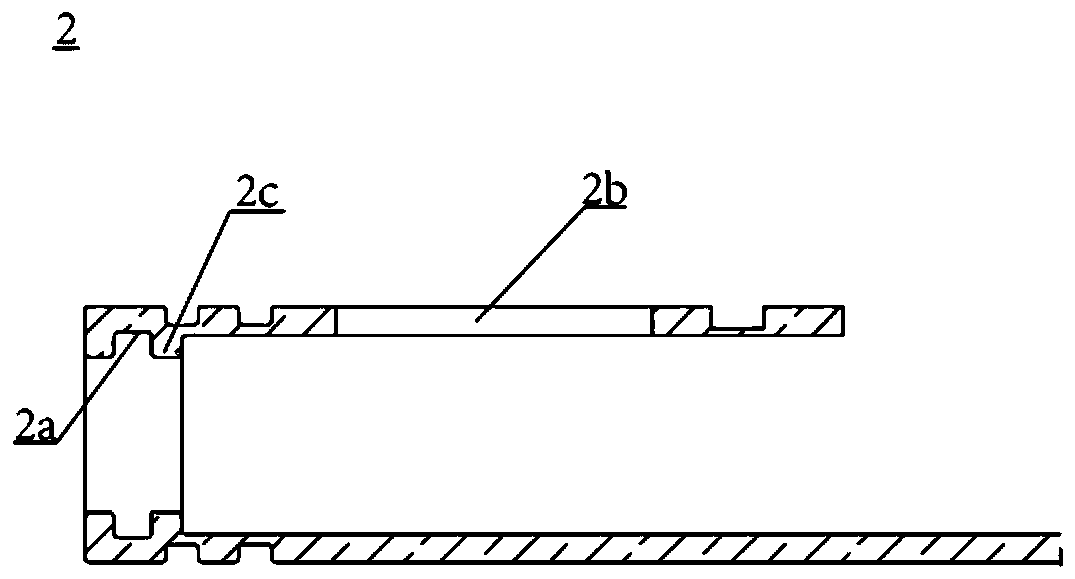

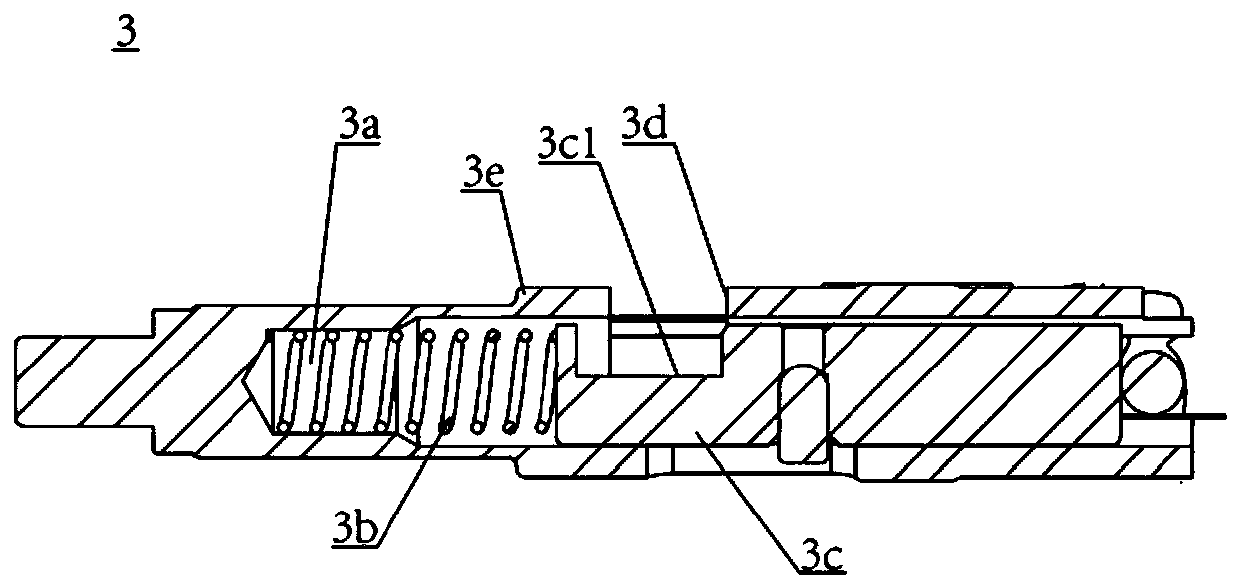

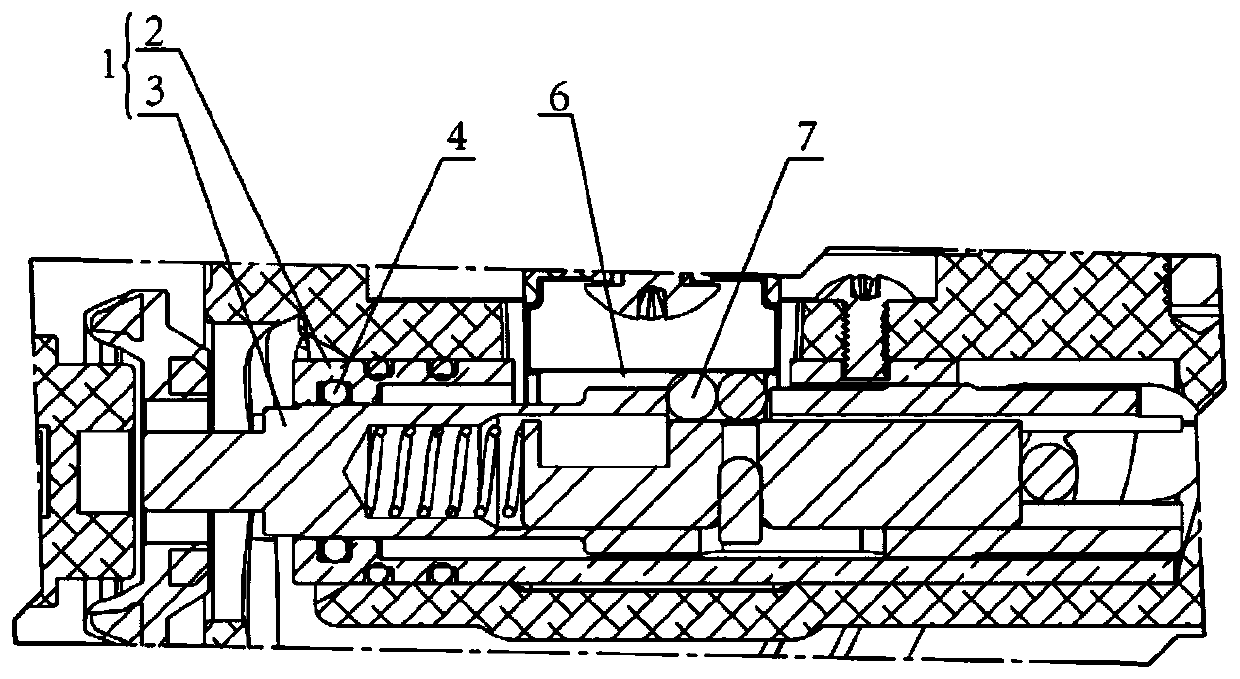

[0037] The first embodiment of the present invention provides a refueling gun 8 , including a switch shaft assembly 1 for controlling the opening or closing of the refueling gun 8 . see figure 1 , figure 2 and Image 6 As shown, the switch shaft assembly 1 includes an outer shaft 3 and an outer shaft sleeve 2 . Wherein, the outer shaft 3 can reciprocate in the outer shaft sleeve 2, which is characterized in that a rod-type seal is adopted between the outer shaft 3 and the outer shaft sleeve 2, and the outer shaft sleeve 2 includes an inner wall and an outer wall of the outer shaft 3. seals (not shown). The axis of the switch shaft assembly 1 and the axis of the main shaft are arranged on the same straight line.

[0038] By arranging the switch shaft assembly 1 and the main shaft on the same straight line, it can be ensured that the main shaft can be triggered when the switch shaft assembly 1 is working, so as to control the opening or closing of the oil gun 8 .

[0039] ...

Embodiment approach 2

[0051] The second embodiment of the present invention provides a fuel gun 8, this embodiment is a further improvement on the first embodiment, the main improvement is that, in this embodiment, see figure 2 with image 3 As shown, the surface roughness of the outer wall of the outer shaft 3 is in the range of Ra0.2-Ra1.2.

[0052] The inventors of the present invention found that when the surface roughness of the outer side wall of the outer shaft 3 is greater than Ra1.2, the wear on the contact surface of the sealing ring 4 is very serious, which not only affects the use feel of the oil gun 8, but also seriously affects the sealing ring 4. service life. And when the surface roughness of the outer shaft 3 is less than Ra0.2, not only will the cost of machining the surface of the outer shaft 3 be greatly increased, but at the same time, because the surface of the outer shaft 3 is too smooth, the sealing ring 4 may adhere to the outer shaft 3, when the outer shaft 3 moves, it ...

Embodiment approach 3

[0056] The third embodiment of the present invention provides a fuel gun 8. This embodiment is a further improvement on the first and second embodiments. The main improvement is that in this embodiment, see figure 1 with figure 2 As shown, a first boss portion 2c is formed on the outer wall of the outer shaft 3, and a second boss portion 3e is provided on the outer sleeve 2, and the first boss portion 2c can abut against the second boss portion 3e. .

[0057] Specifically, in this embodiment, one end of the outer shaft sleeve 2 is formed with a second boss portion 3e, wherein the second boss portion 3e extends inward from the inner wall of the outer shaft sleeve 2 and forms a ring shape, and the sealing groove 2a is arranged on the side wall of the second boss portion. Correspondingly, a first boss portion 2c capable of abutting against it is formed on the outer wall of the outer shaft 3, wherein the first boss portion 2c is formed by extending outward from the outer side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com