Welding robot capable of moving in all directions

A welding robot, omnidirectional moving technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. To move the function, meet the needs of use, the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

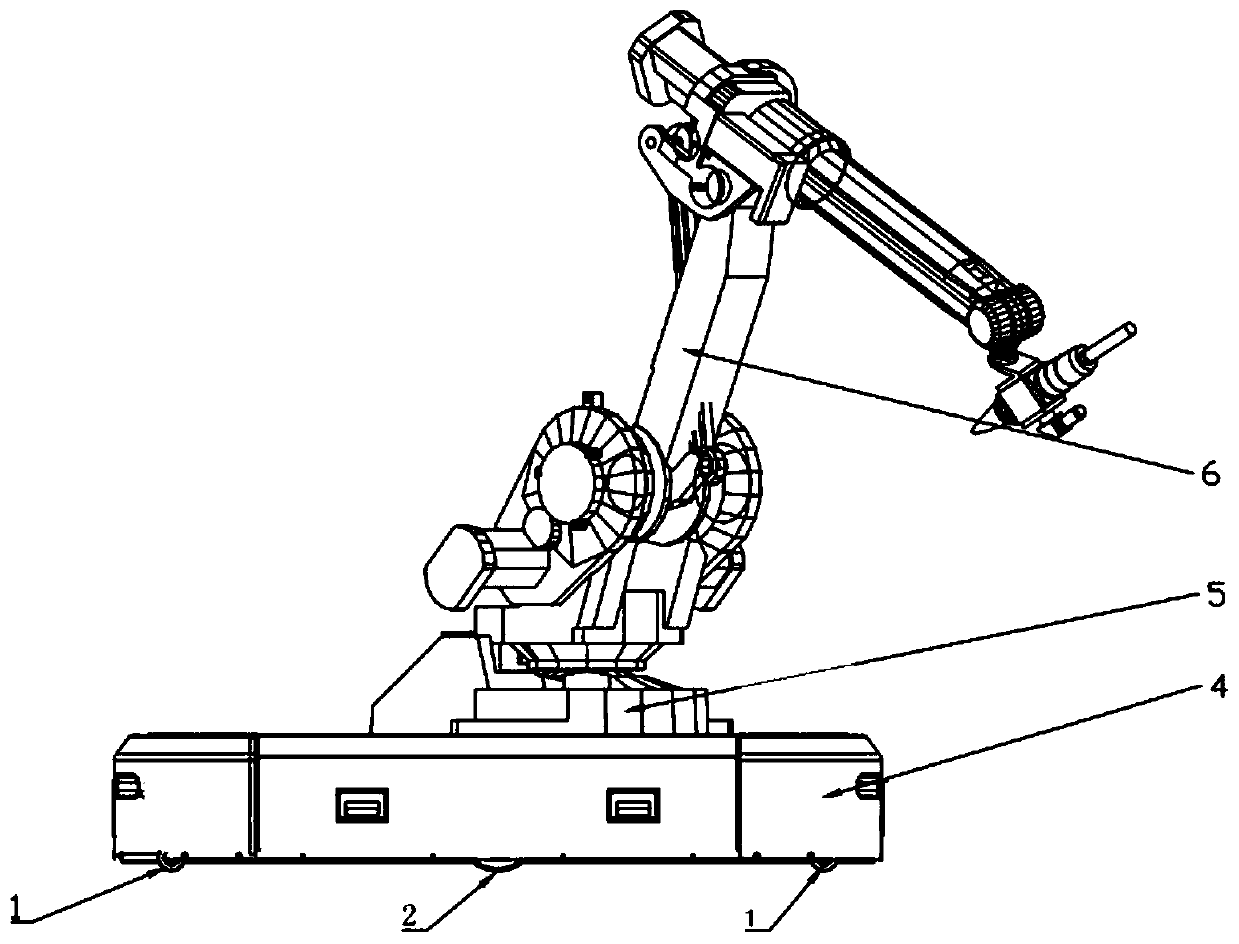

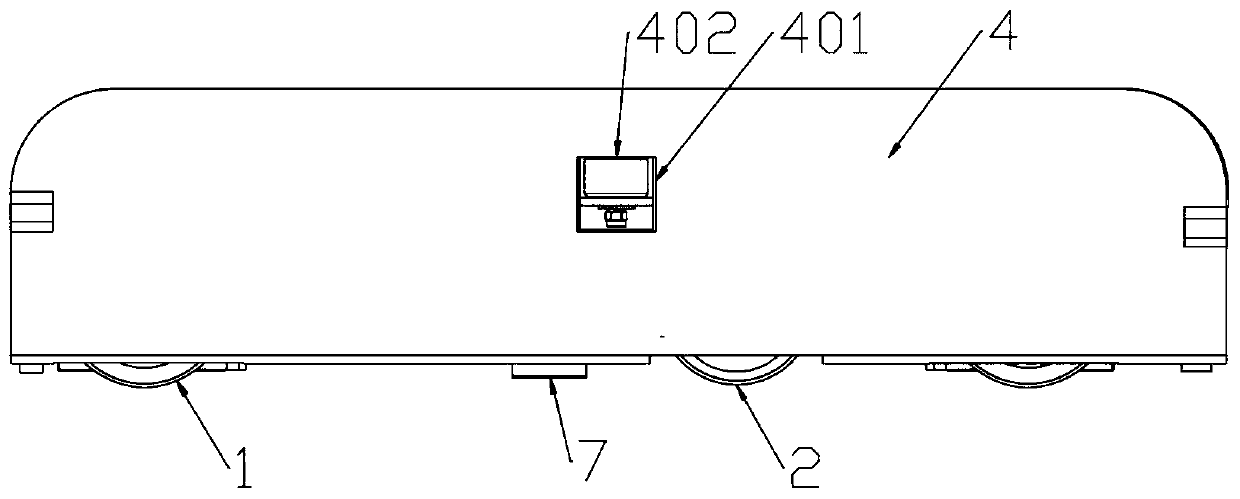

[0029] Such as figure 1 , figure 2 as well as image 3 As shown, a welding robot that can move in all directions includes a vehicle body and a welding robot assembly 6 installed on the vehicle body. The bottom of 4 is provided with chassis 3, and this chassis 3 is provided with driving wheel assembly 2 and driven wheel assembly 1, and described chassis 3 is also provided with first driving motor 101, second driving motor 201, first driving motor The output shaft of 101 is connected with a gear 102, and the gear 102 is meshed with a rack 103, and the rack 103 is movably connected on the chassis 3. Specifically, a slide rail may be set on the chassis, a slider is arranged at the lower end of the rack, and the slider is placed On the slide rail, connecting blocks 104 are fixed at both ends of the rack 103, and each connecting block 104 is movably connected with a first connecting rod 105, and one end of the first connecting rod 105 is fixed to the connecting block 104 through ...

Embodiment 2

[0035] This embodiment is further optimized on the basis of Embodiment 1. Specifically, the differential 204 includes a fixed piece 2041 and four idler gears that mesh with each other and form a square structure, which are respectively the first idler gear 2044 and the second idler gear 2044. Idling gear 2043, the 3rd idler gear 2046 and the 4th idler gear 2045, described first idler gear 2044 is fixed on described drive shaft 205 one end place that is fixed with from gear 203, the 3rd idler gear 2046 is fixed on opposite other On the driving shaft of the driving wheel assembly 1, the second idler gear 2043 and the fourth idler gear 2045 are connected by setting a driven shaft 2042, and the driven shaft 2042 is fixed on the fixing member 2041, and the fixing member 2041 is movably connected On the drive shaft 205; the function of speed regulation is realized. When the output shaft of the second drive motor 201 drives the main gear 202 to rotate, thereby driving the slave gear ...

Embodiment 3

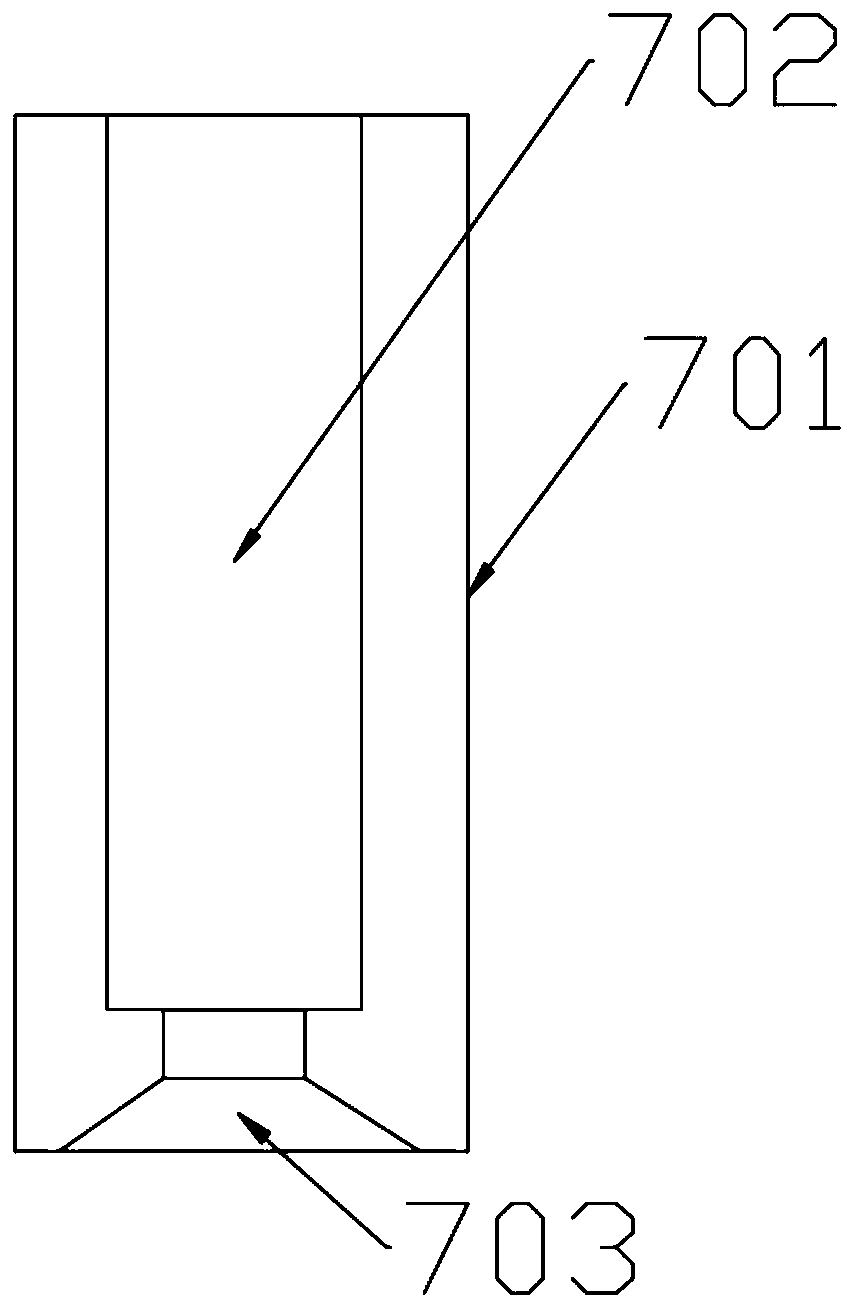

[0037]This embodiment is further optimized on the basis of Embodiment 2. Specifically, the bottom of the chassis 3 is also provided with a support leg 7. The support leg 7 includes a hollow fixed column 701, and a hydraulic cylinder is arranged inside the hollow fixed column 701. 702, one end of the telescopic rod of the hydraulic cylinder 702 is fixed with a support plate 703. In practice, the height of the hollow fixed column 701 is smaller than the height of the driving wheel assembly 2; specifically, the bottom of the support plate 703 is set With rubber pads.

[0038] Because during positioning welding, the movement of the vehicle body may occur, so this setting can use supporting legs for positioning during positioning, which is more conducive to welding and improves welding quality. The setting of rubber pads can also serve the purpose of anti-skid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com