Slurry filtering device and method

A technology of filtering device and discharging device, which is applied in the fields of filtering and separation, separation method, chemical instrument and method, etc., can solve the problems of high equipment cost, blockage of blanking port, complicated operation, etc., and achieve the effect of improving quality and production speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following are preferred embodiments of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can also be made, and these improvements and modifications are also considered as the present invention. protection scope of the invention.

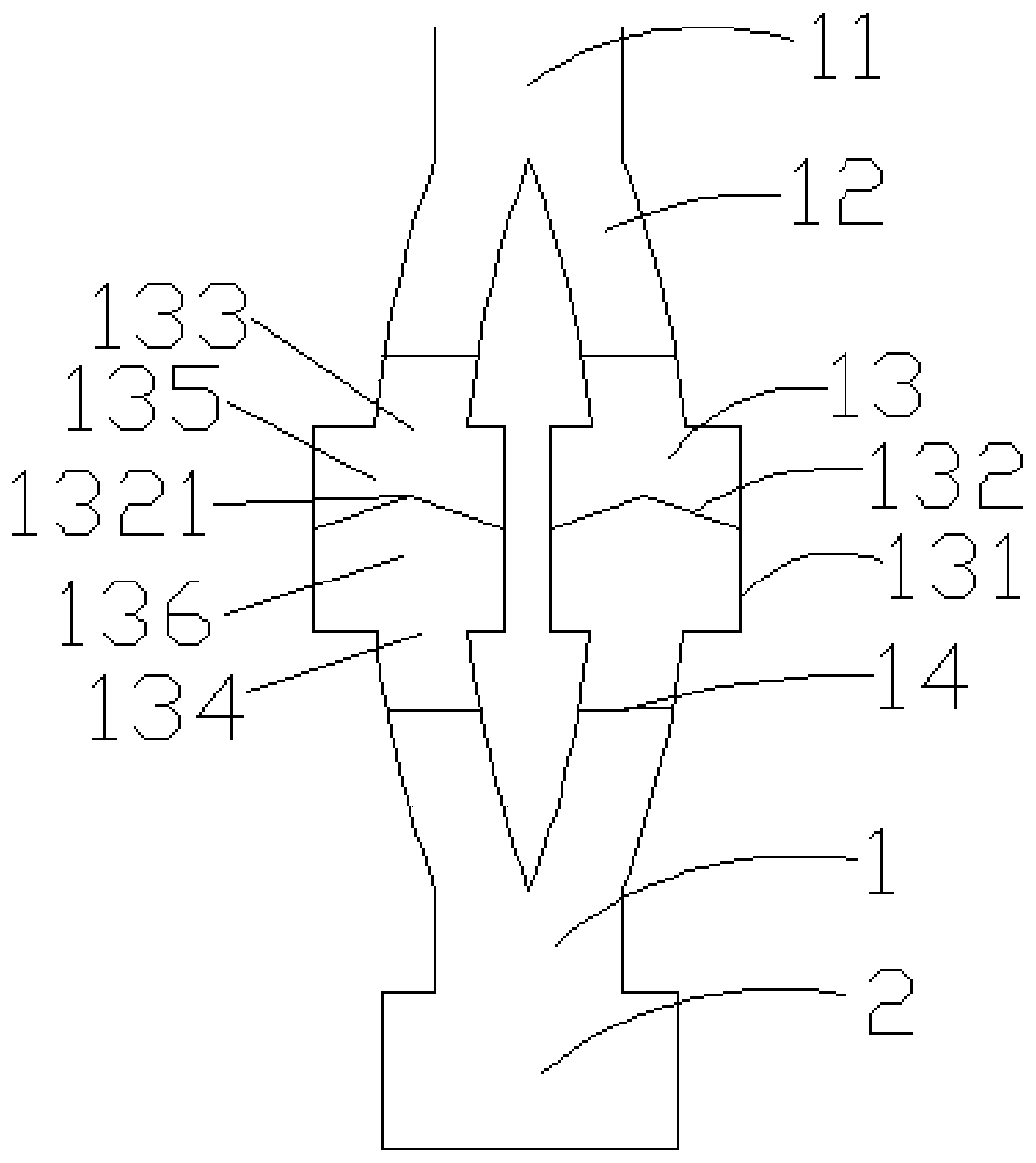

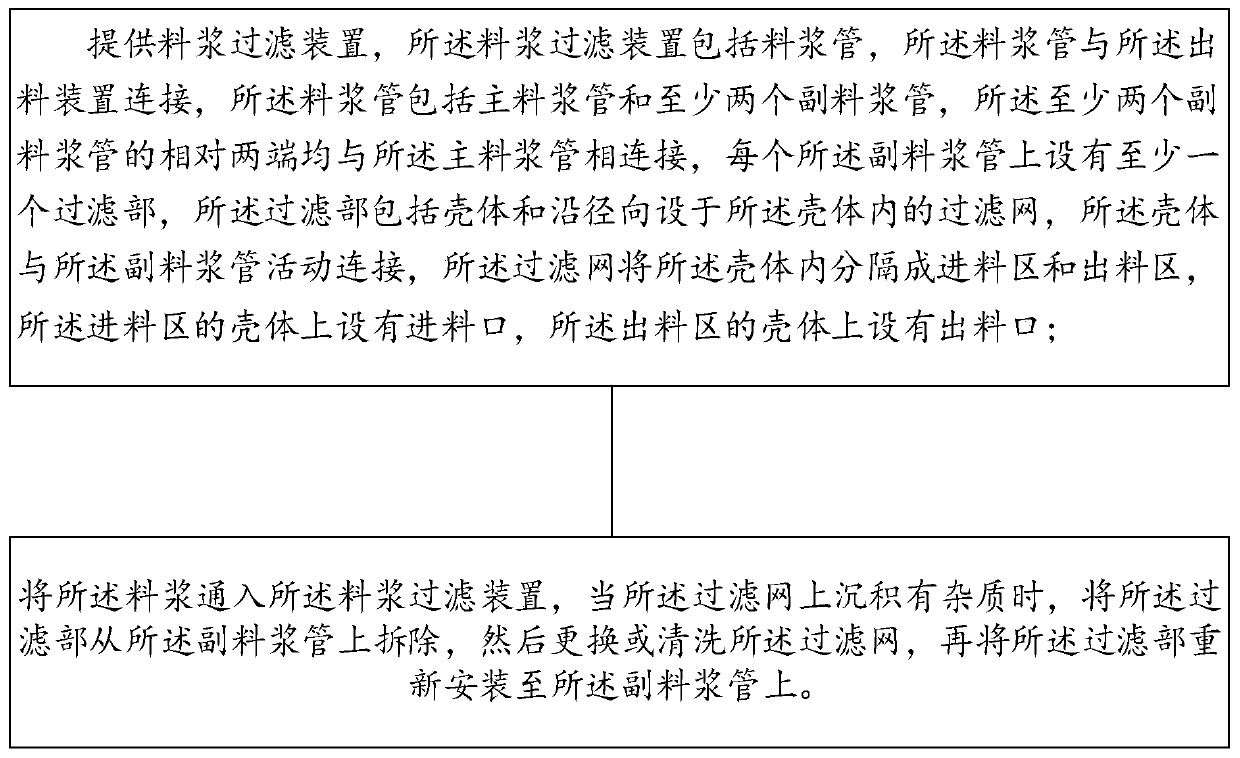

[0023] Please refer to figure 1 , a kind of slurry filtering device provided by the embodiment of the present invention, comprises slurry pipe 1, and described slurry pipe 1 is connected with described discharging device 2, and described slurry pipe 1 comprises main slurry pipe 11 and at least two A secondary material slurry pipe 12, the opposite ends of the at least two secondary material slurry pipes 12 are connected to the main material slurry pipe 11, and each of the secondary material slurry pipes 12 is provided with at least one filter part 13 , the filter part 13 includes a housing 131 and a filter scr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com