Washing method of washing system

A washing method and washing chamber technology, applied in the field of kitchen washing, can solve problems such as reducing user experience, affecting washing efficiency, and inability to use with peace of mind, and achieve the effects of improving predictability, improving washing efficiency, and improving user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

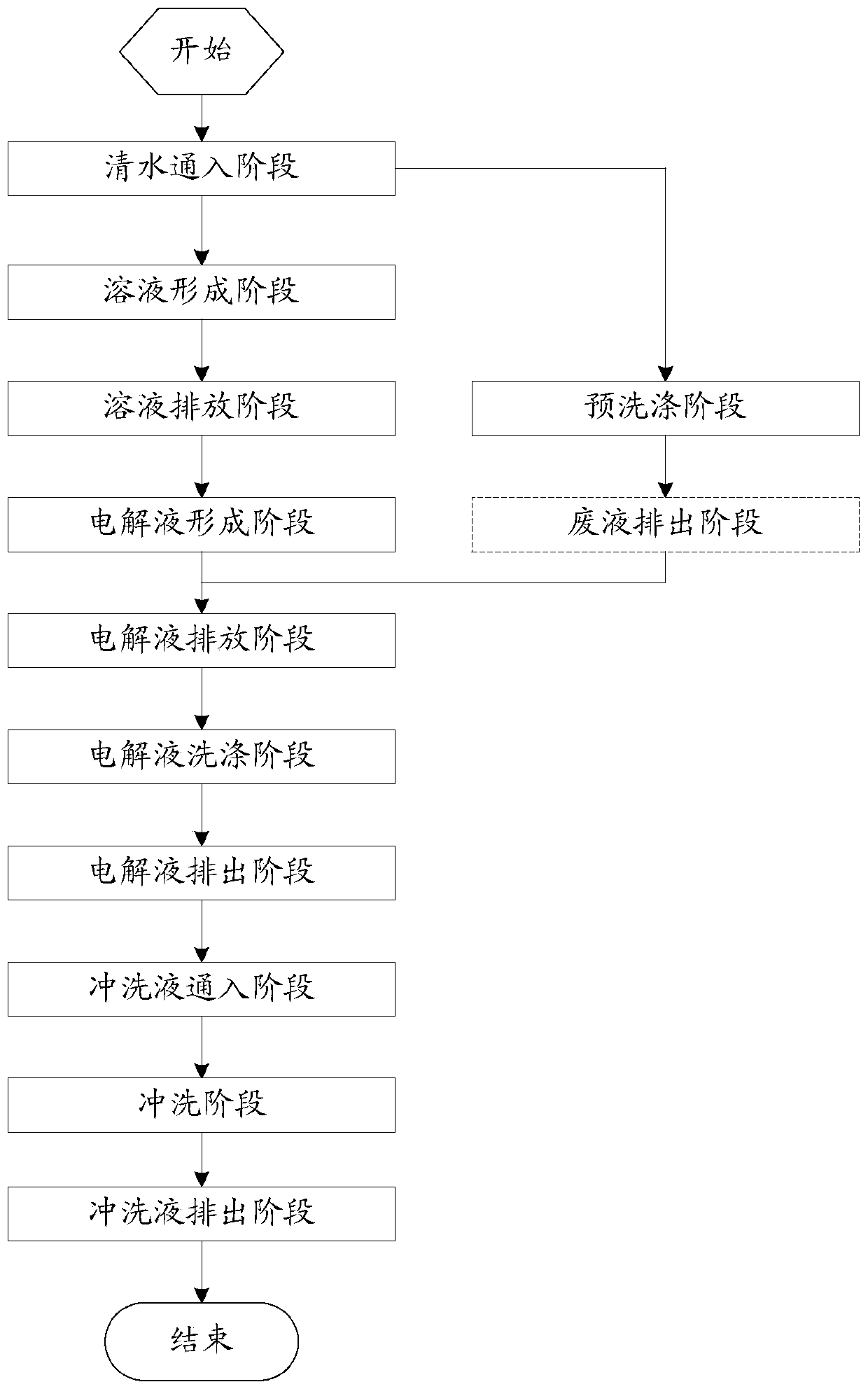

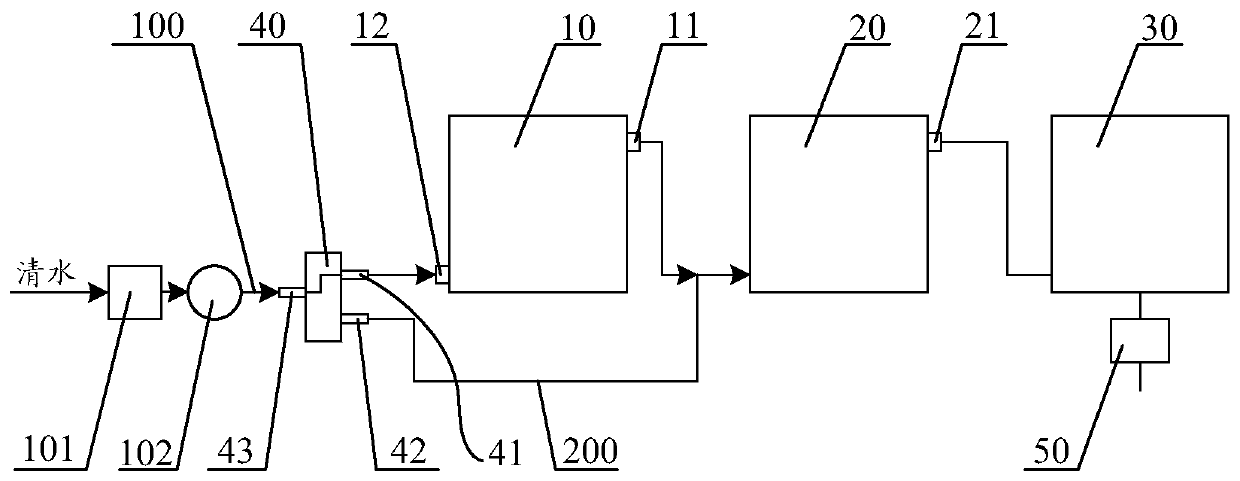

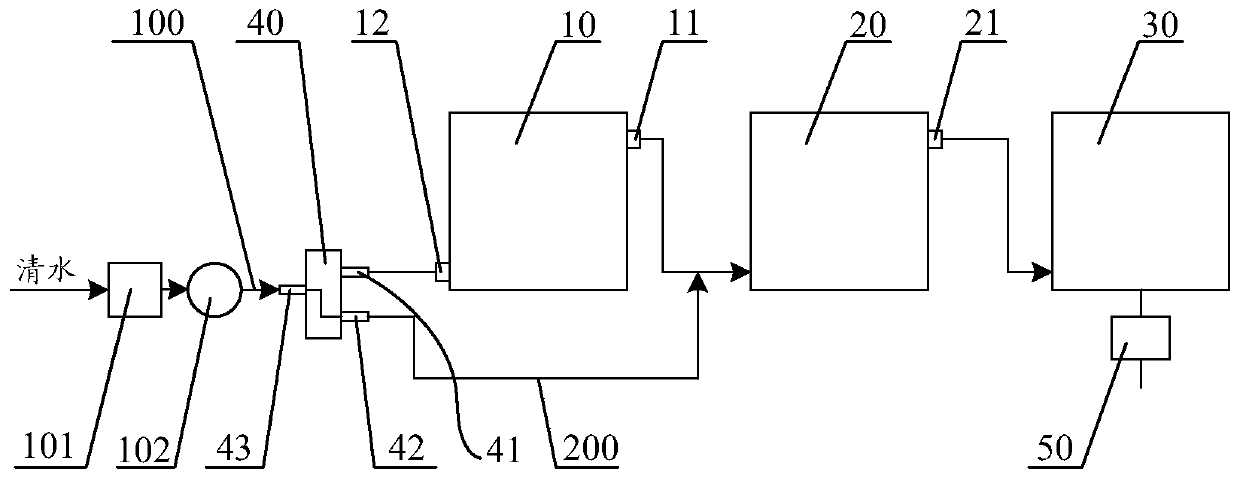

[0050] figure 1 It is a schematic flowchart of the washing method of the washing system according to the first embodiment of the present invention. figure 2 It is a structural schematic diagram of the washing system in the first embodiment of the present invention. combine figure 1 and figure 2, The washing system includes a dissolution chamber 10 , an electrolysis chamber 20 and a washing chamber 30 . The dissolving chamber 10 is used for containing solute and dissolving the solute to form an electrolyte solution. An electrolysis electrode is arranged in the electrolysis chamber 20, and the electrolysis chamber 20 is used to electrolyze the electrolyte solution to form an electrolyte solution. Items to be washed are contained in the washing cavity 30 , and the items are washed in the washing cavity 30 . The dissolution chamber 10 communicates with the electrolysis chamber 20 , and the electrolysis chamber 20 communicates with the washing chamber 30 . The washing metho...

no. 2 example

[0090] Figure 4 It is a schematic flowchart of the washing method of the washing system according to the second embodiment of the present invention. Different from the first embodiment, in this embodiment, if Figure 4 As shown, in the pre-washing process, the clean water feeding stage and the pre-washing stage are circulated successively for at least two rounds. During the electrolyte washing process, at least two rounds of the solution forming stage, the solution discharging stage, the electrolyte forming stage, the electrolyte discharging stage and the electrolyte washing stage are sequentially cycled. During the rinsing process, the rinsing solution passing phase and the rinsing phase are sequentially circulated for at least two rounds.

[0091] In order to further save washing time, in the pre-washing process, the solution formation stage, solution discharge stage and electrolyte formation stage can be carried out at the same time as the last round of pre-washing stage...

no. 3 example

[0096] Figure 5 It is a schematic diagram of liquid flow in the electrolyte discharge stage in the third embodiment of the present invention. The difference from the first embodiment is that in this embodiment, the drainage aid pipeline includes a dissolution chamber 10, the drainage aid fluid includes an electrolyte solution, and the electrolyte discharge stage is specifically:

[0097] The water injection pipeline 100 feeds clean water into the dissolving chamber 10 through the water inlet 12, so that the dissolving chamber 10 feeds the electrolytic solution into the electrolytic chamber 20, and then the electrolytic chamber discharges the electrolyte to the washing chamber.

[0098] In this embodiment, after the electrolyte discharge stage, the water injection pipeline 100 needs to pass clean water into the washing chamber through the clean water pipeline 200 and the electrolysis chamber 20, so as to cooperate with the electrolyte to complete the electrolyte washing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com