A straight gear meshing stiffness calculation method considering a complex matrix and a crack propagation path

A technology of crack propagation and meshing stiffness, which can be used in calculations, special data processing applications, instruments, etc., and can solve problems such as errors, difficult operation, and many interference factors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

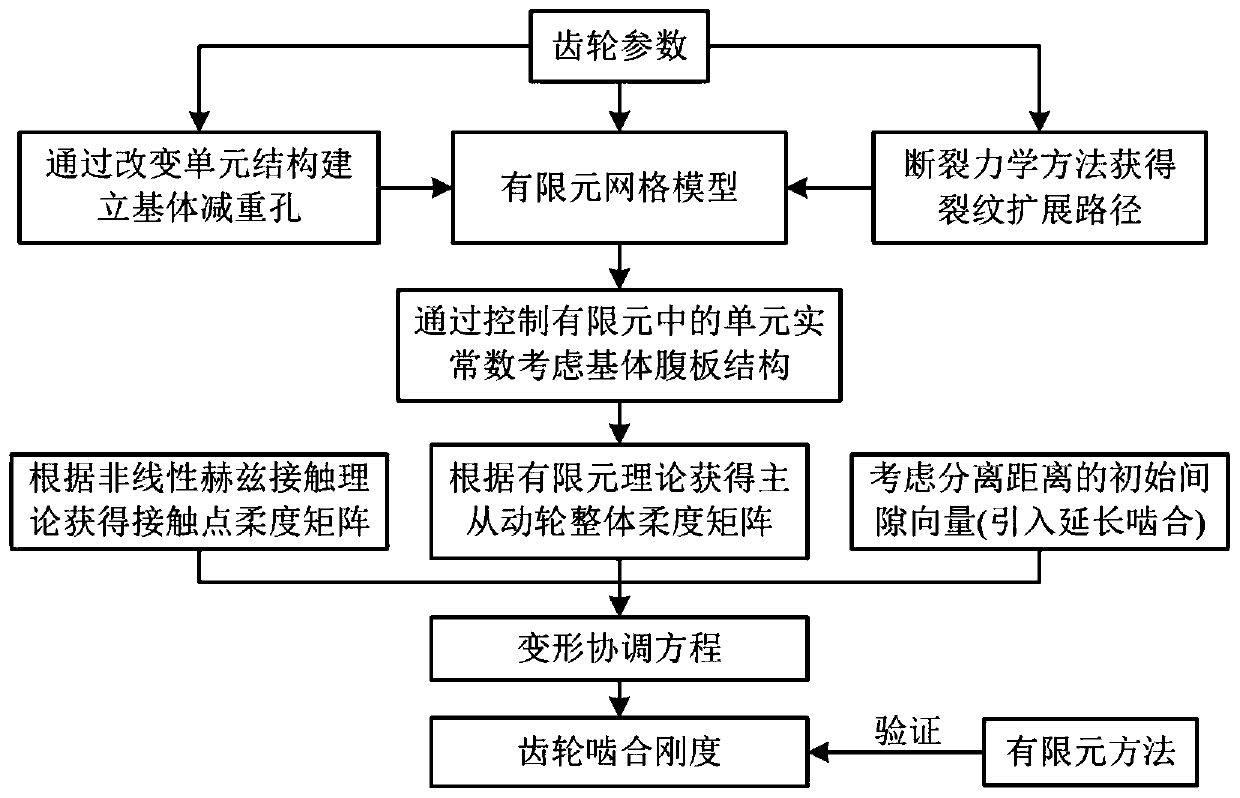

[0084] A method for calculating meshing stiffness of spur gears considering complex matrix and crack propagation path, such as figure 1 As shown, it mainly includes the following steps: Step 1: Determine the basic parameters of the spur gear pair, web parameters, weight-reducing hole parameters and initial crack parameters;

[0085] Step 2: Determine the initial crack parameters and simulate the crack propagation path. The specific steps are as follows:

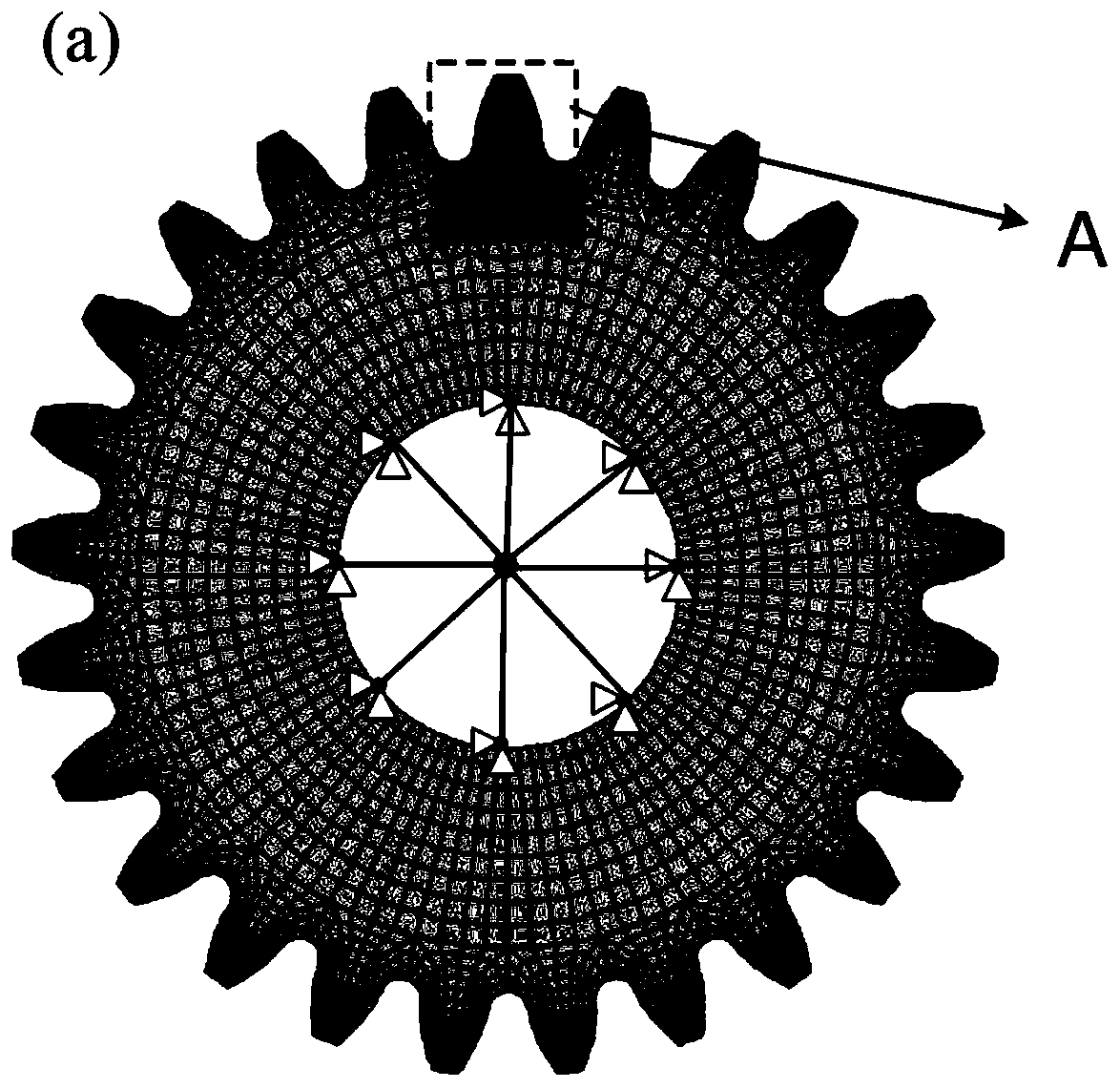

[0086] Step 2.1: According to the spur gear pair parameters determined in step 1, a finite element model with initial cracks is established in ANSYS software, and the finite element model with singular elements is established as Figure 2a Shown

[0087] Step 2.2: Use ANSYS software to perform stress intensity factor K I And K II The solution. Based on the stress intensity factor K obtained in ANSYS I And K II , According to the maximum tangential stress fracture criterion, the crack propagation angle θ n The calculation method...

Embodiment 2

[0130] A method for calculating the meshing stiffness of a spur gear considering the complex matrix and crack propagation path. This embodiment is based on the first embodiment and includes the following steps:

[0131] Step 1: Determine the basic parameters of the spur gear pair and the position of the web and the parameters of the weight reduction hole;

[0132] Step 2: Determine the initial crack parameters and simulate the crack propagation path. For details, please refer to Step 2 of the Summary of the Invention;

[0133] Step 3: Based on the finite element theory and the load-bearing gear tooth contact analysis method, calculate the compliance matrix of the driving and driven gear with complex matrix and cracks. For specific implementation methods, refer to step 3 in the summary of the invention;

[0134] Step 4: Use deformation coordination equation and Hertz contact theory to carry out static transmission error x s , And then calculate the gear meshing stiffness k considering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com