Pot clay brick for gas-permeable environmentally-friendly plazas

An environmentally friendly, clay-based technology, applied in the field of building materials, can solve the problems of long production cycle and easy cracking, and achieve the effects of consistent drying speed, good air permeability, and mitigation of heat island effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

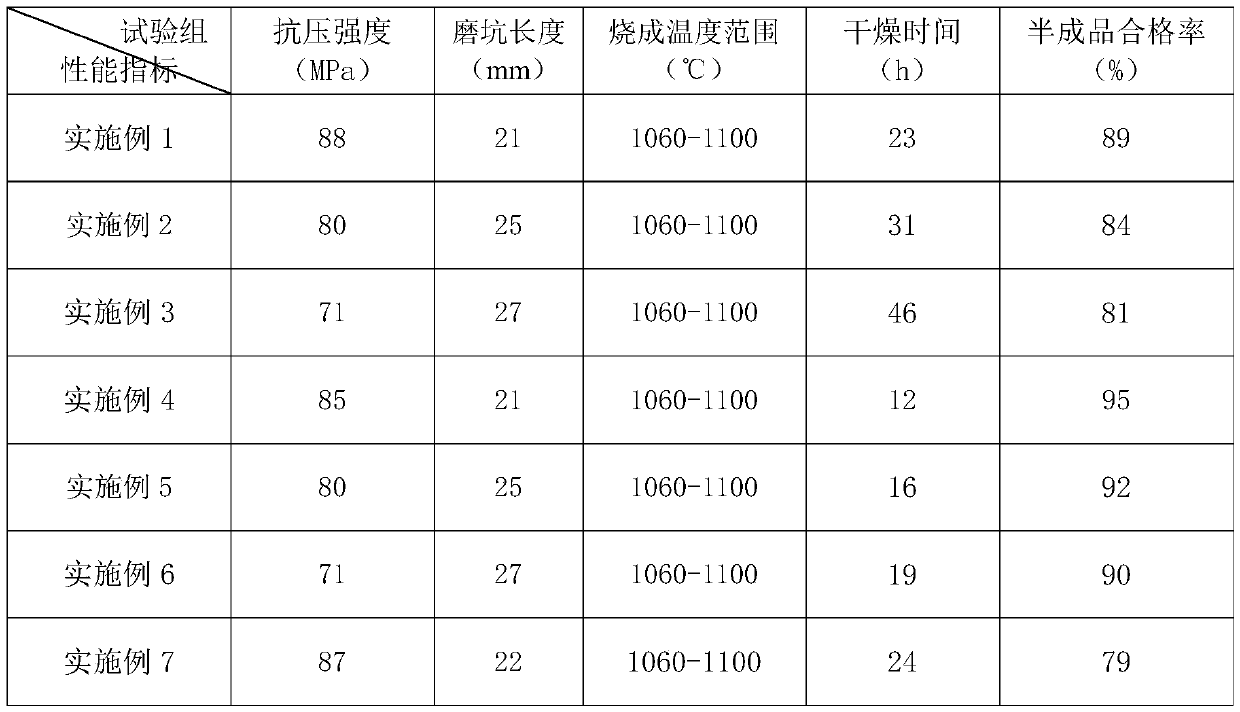

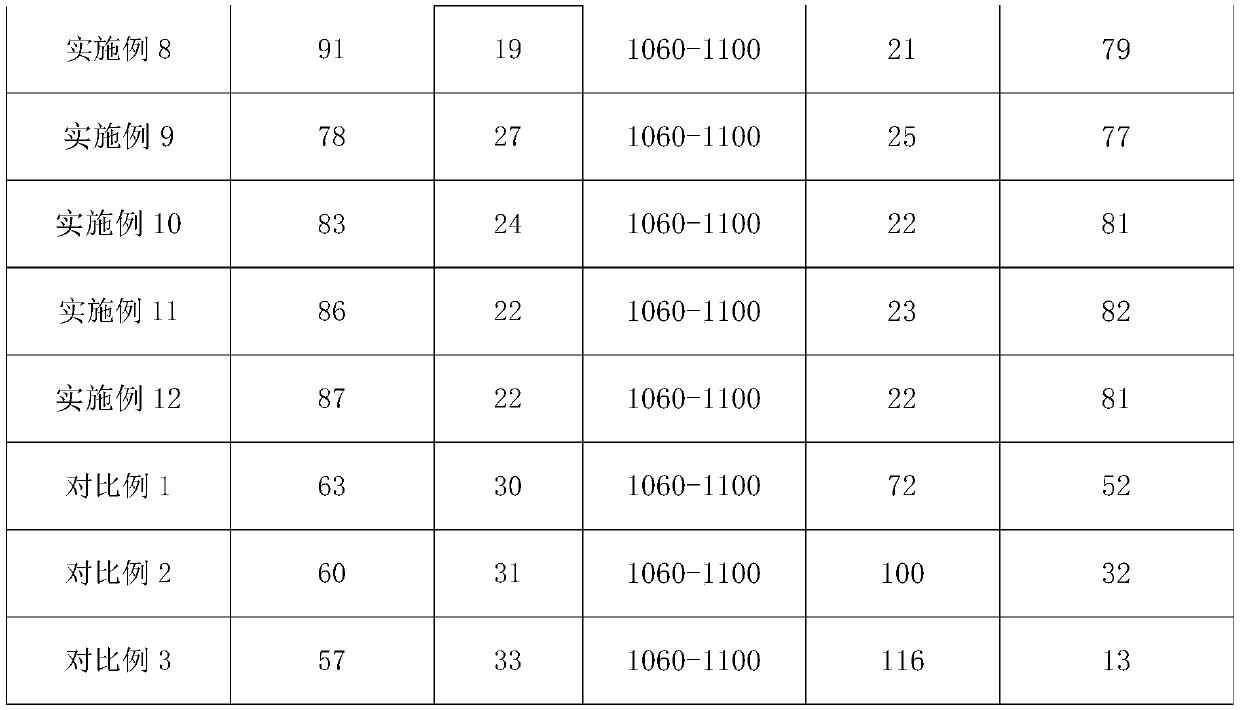

Embodiment 1

[0052] This embodiment discloses a breathing-type environment-friendly clay brick for squares, which includes the following raw materials: Chongqing clay, Renshou clay, Guihua town clay and sintered clay, and the weight ratio of the Chongqing clay, Renshou clay and Guihua town clay is 32 %; the mass ratio of the Chongqing pottery clay, Renshou pottery clay and Guihua Town pottery clay is 1:1:2.

[0053] The preparation of above-mentioned breathable environment-friendly plaza with clay brick comprises the following steps:

[0054] (1) Prepare the following raw materials: Chongqing pottery clay, Renshou pottery clay, Guihua town pottery clay and sintered pottery clay;

[0055] (2) above-mentioned raw material is carried out crushing, the particle diameter of raw material is controlled below 50mm;

[0056] (3) Carry out ball milling to raw material, the particle diameter of raw material is controlled at 200 orders, and water content is controlled at 48%;

[0057] (4) squeeze mu...

Embodiment 2

[0063] This embodiment discloses a breathing environment-friendly clay brick for squares, which includes the following raw materials: Chongqing clay, Renshou clay, Guihua Town clay and sintered clay, and the weight ratio of the Chongqing clay, Renshou clay and Guihua Town clay is 40% %; the mass ratio of the Chongqing pottery clay, Renshou pottery clay and Guihua Town pottery clay is 1:0.8:2.1.

[0064] The preparation of above-mentioned breathable environment-friendly plaza with clay brick comprises the following steps:

[0065] (1) Prepare the following raw materials: Chongqing pottery clay, Renshou pottery clay, Guihua town pottery clay and sintered pottery clay;

[0066] (2) above-mentioned raw material is carried out crushing, the particle diameter of raw material is controlled below 50mm;

[0067] (3) Carry out ball milling to raw material, the particle diameter of raw material is controlled at 200 orders, and water content is controlled at 48%;

[0068] (4) squeeze mu...

Embodiment 3

[0074] This embodiment discloses a breathing environment-friendly clay brick for squares, including the following raw materials: Chongqing clay, Renshou clay, Guihua town clay and sintered clay, the weight ratio of Chongqing clay, Renshou clay and Guihua town clay is 45% %; the mass ratio of the Chongqing pottery clay, Renshou pottery clay and Guihua Town pottery clay is 0.8:1:2.1.

[0075] The preparation of above-mentioned breathable environment-friendly plaza with clay brick comprises the following steps:

[0076] (1) Prepare the following raw materials: Chongqing pottery clay, Renshou pottery clay, Guihua town pottery clay and sintered pottery clay;

[0077] (2) above-mentioned raw material is carried out crushing, the particle diameter of raw material is controlled below 50mm;

[0078] (3) Carry out ball milling to raw material, the particle diameter of raw material is controlled at 200 orders, and water content is controlled at 48%;

[0079] (4) squeeze mud dehydration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Grinding pit length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com