A fully flexible bidirectional torsional actuator

A fully flexible actuator technology, applied in the direction of program control manipulators, manufacturing tools, manipulators, etc., can solve the problems of limited movement flexibility and inability to realize two-way torsion, and achieve the effect of simple production, flexible torsion and flexible movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

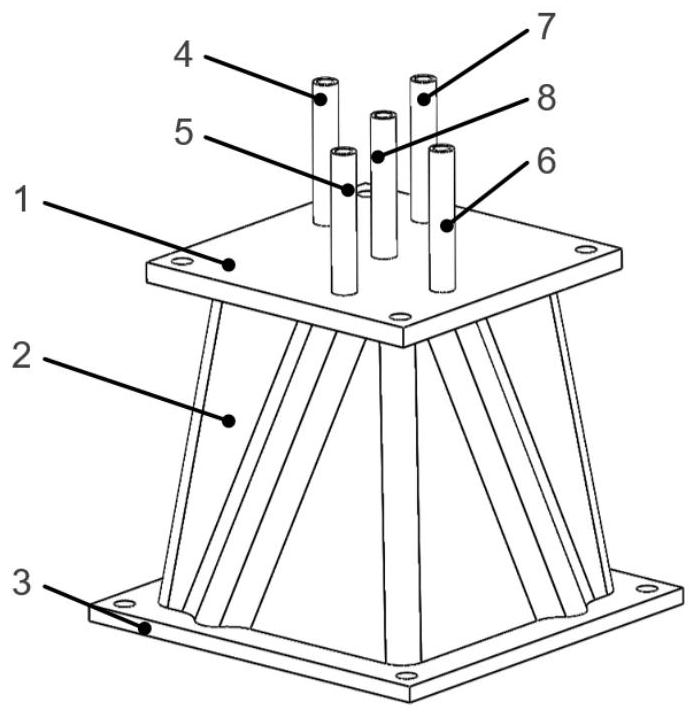

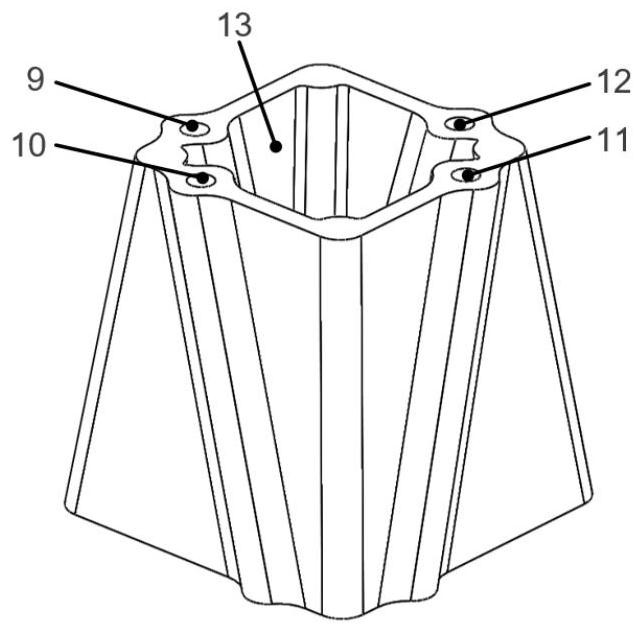

[0024] like figure 1 As shown, the side curved surface 2 is sealed and connected between the upper bottom surface 1 and the lower bottom surface 3, so that the torsion actuator forms a sealed main air chamber 13. The side curved surface 2 is mainly composed of four sides, and each side has a The through cylindrical cavity is used as a control air chamber, and each control air chamber is inclined along one of the diagonal lines of its respective side, that is, each control air chamber is inclined clockwise or counterclockwise on the side curved surface 2 . The inclination directions of the control air chambers on the two adjacent sides are opposite, that is, opposite in the clockwise or counterclockwise direction; the inclination directions of the control air chambers on the two opposite sides are centrally symmetrical, that is, in the same clockwise or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com