Method for producing a stator, and teeth stack for a stator

A technology of tooth stack and stator, applied in the field of tooth stack, can solve the problems of high production force, loss of motor characteristics and/or efficiency, and high cost of stator production, and achieve the effect of rapid assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

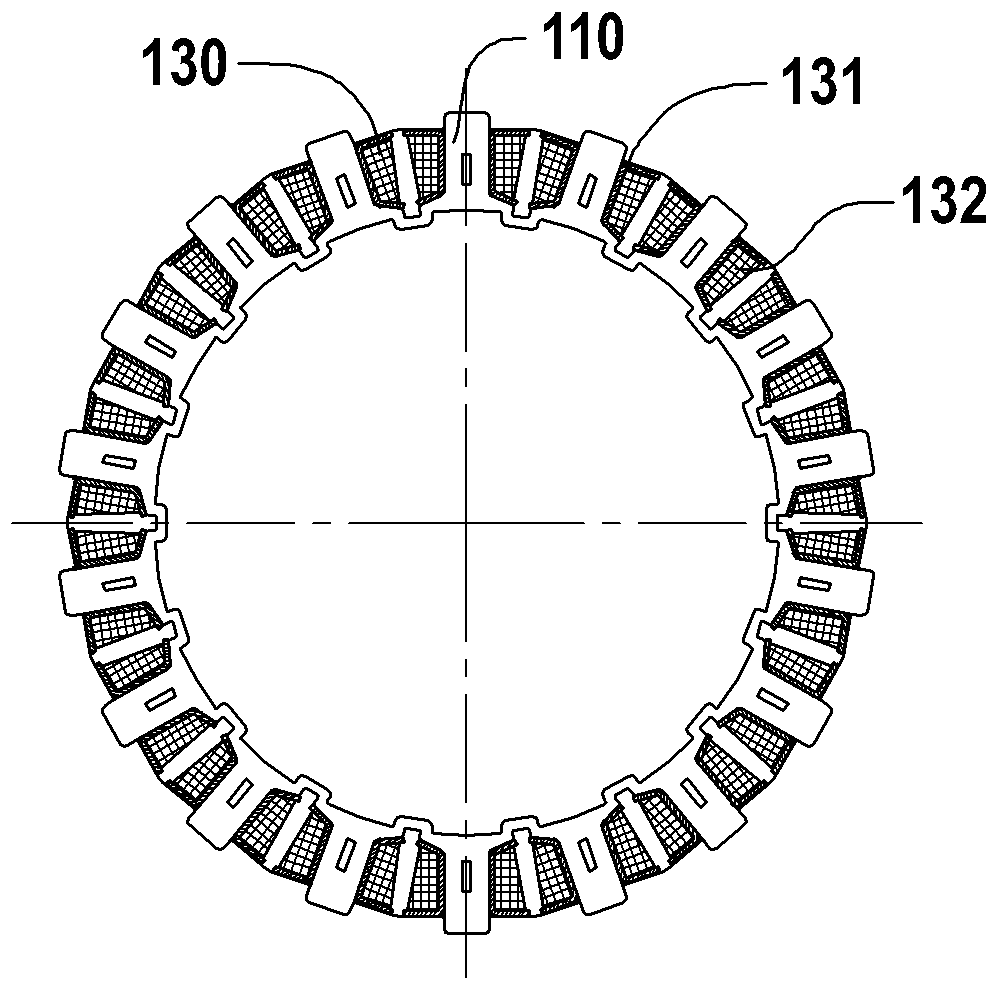

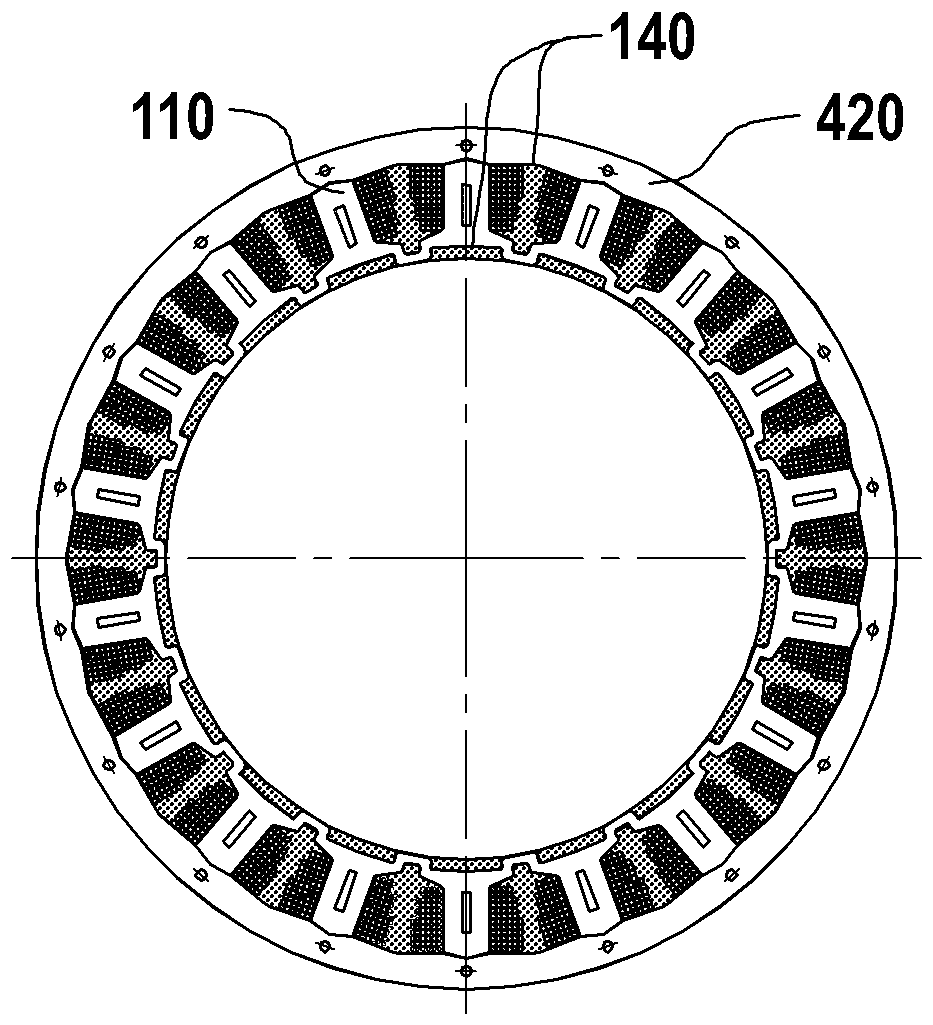

[0068] Figure 2A to Figure 2F Several steps of the production method of the stator 100 according to the first preferred embodiment are schematically depicted. Such as Figure 2A As shown, a tooth lamination 110 is provided in a first step, wherein the tooth lamination 110 is provided as a laminated tooth lamination.

[0069] The tooth lamination 110 comprises several teeth 111 which are pressed into sheets and arranged such that the tooth lamination 110 forms a circular structure, wherein the teeth 111 are arranged radially with respect to the center 1000 of the circular structure. direction. The teeth 111 each comprise interlocking or interlockable elements 112 for attaching several tooth laminations 110 together one above the other.

[0070] Furthermore, each tooth 111 comprises a root end 113 and an inner end 115, wherein the root end 113 is arranged in a radially outward direction, ie away from the center 1000, and wherein the inner end 115 is arranged radially inwardl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com