A method for efficient utilization of old heat exchange equipment for improving industrial heat exchange network

A heat exchange network and heat exchange equipment technology, applied in heat exchange equipment, lighting and heating equipment, complex mathematical operations, etc., can solve problems such as energy and resource waste, reduce investment costs, avoid irrationality, and increase area The effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to reflect the effectiveness and superiority of the present invention in practical application, the method is now described in detail through specific cases.

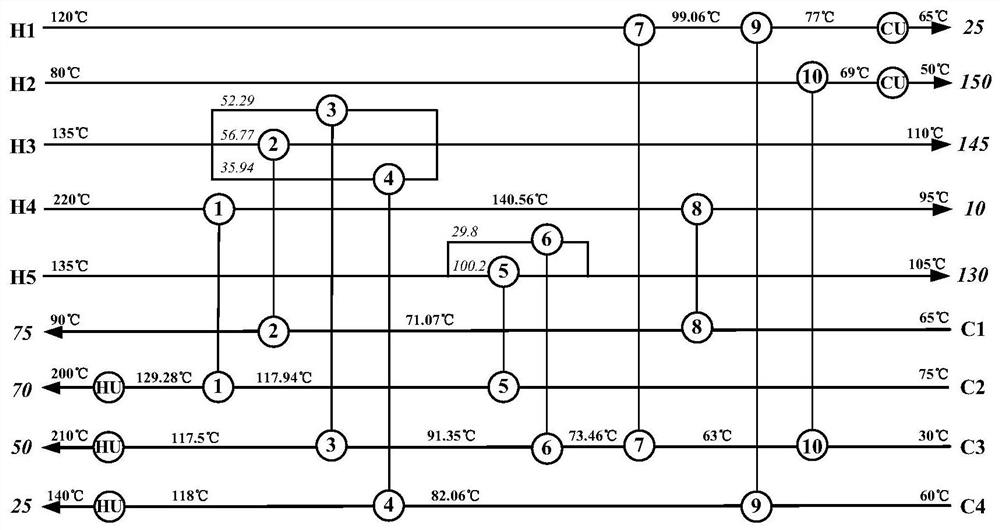

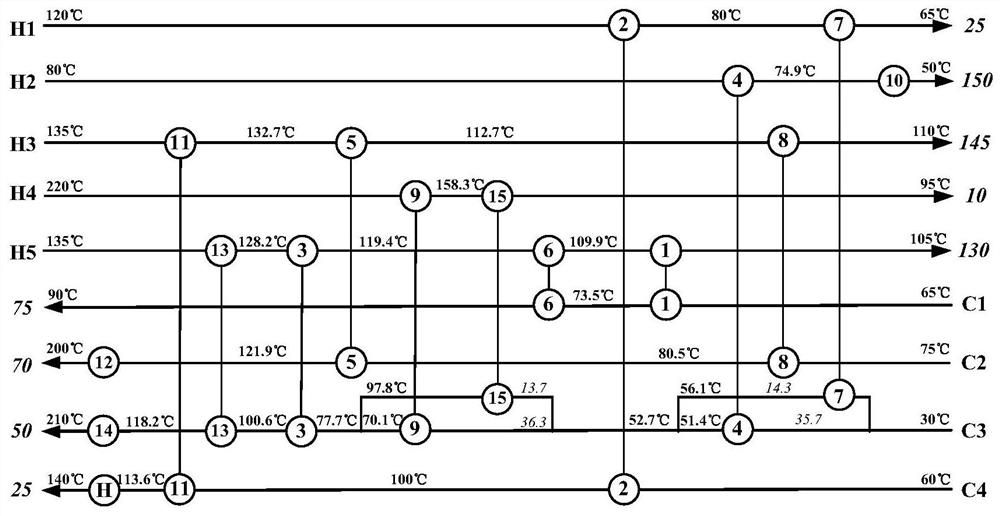

[0035] refer to Figure 1 ~ Figure 4 , a method for efficient utilization of old heat exchange equipment to improve the industrial heat exchange network. This case includes 5 hot streams, 4 cold streams, 1 hot utility and 1 cold utility. The logistics data and heat exchanger cost calculation formula are shown in Table 1, and the heat exchanger data are shown in Table 2. The existing heat exchange network structure is as follows figure 2 shown. The annual operating cost of the existing heat exchange network is 1.145×10 6 $ / y, the service life of the equipment is 6 years, and the annual interest rate is 10%; see Table 2 for the heat exchange area requirements of the transformed network.

[0036]

[0037] Table 1

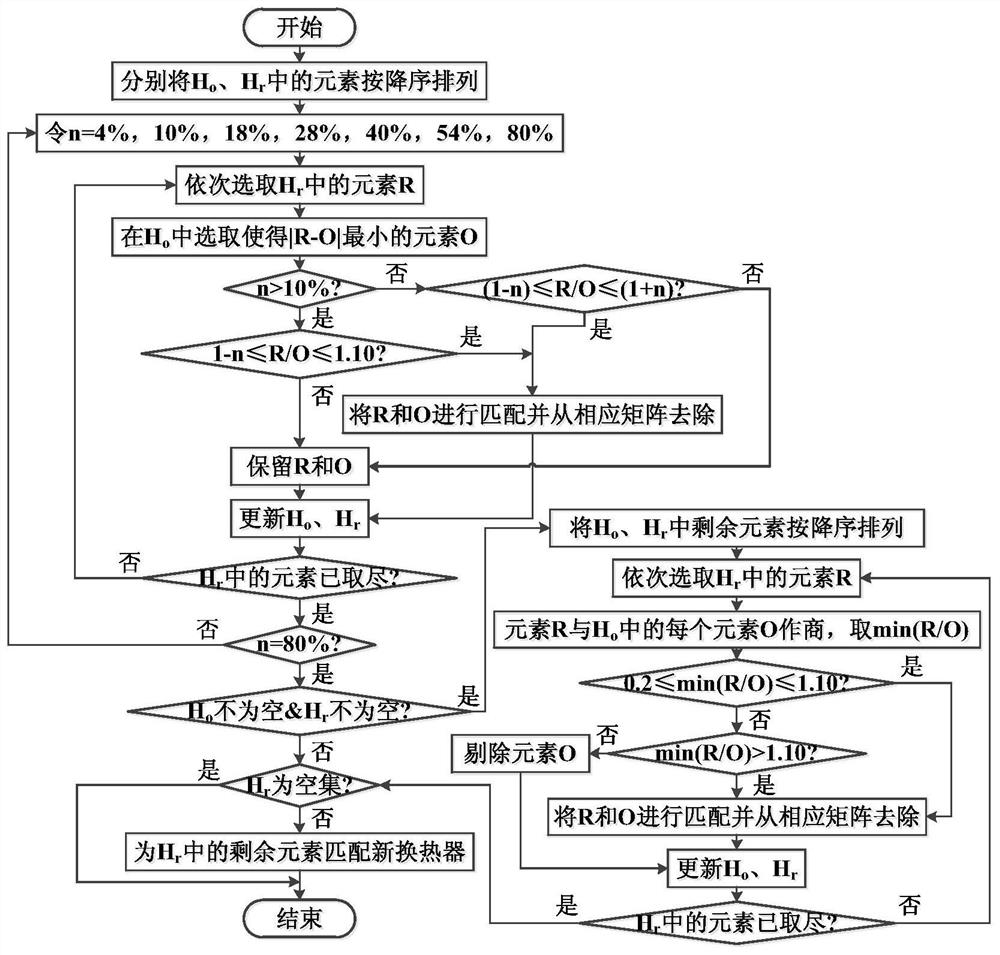

[0038] combine figure 1 As shown in the old equipment reuse flow chart, the implemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com